Vapour Recovery Systems/Units (VRU)

The prevailing method of vapour recovery globally is, and has been for decades, adsorption of the VOCs (volatile organic compounds which are chemicals that have high vapour pressure like Petrol, Diesel, Methanol, Crude Oil, Benzene, paints and coatings..etc) onto activated carbon. Following adsorption, the activated carbon is regenerated by applying vacuum to these, the so-called pressure swing adsorption principle.

Vapour Recovery Benefits

– Economical Benefits :

- Up to 1% Vol. of the liquid, evaporates and is lost from crude oil extraction to the end-user driving the vehicle if no means of emission prevention is taken

- Typical payback period of one to two years for vapour recovery equipment.

-Safety Benefits:

- Potentially explosive environments are avoided in storages, loading facilities and service stations when VOC vapour is captured and treated

– Environmental Benefits:

- VOCs form ground-level ozone and smog affecting lung elasticity and ability to resist diseases, ageing lungs prematurely, and damages green leaves tissue, affecting the plants’ ability to grow

- Some VOCs are carcinogenic, mutagenic and teratogenic in nature.

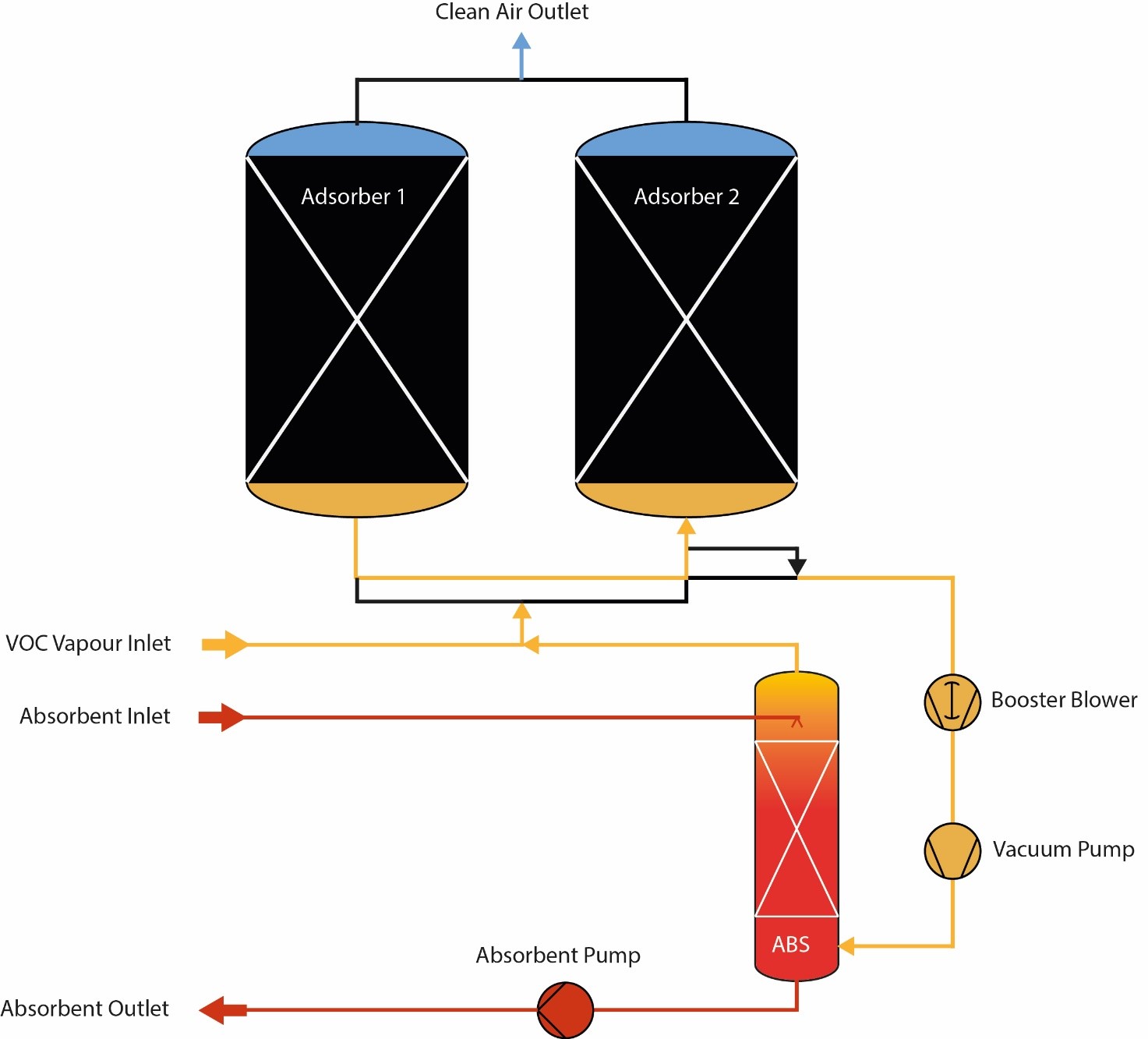

The mixture of air and VOC vapour is lead to a carbon filter, where the VOC is retained by adsorption on the carbon, and the clean air passes through the vent to the atmosphere.

After a period of typically 15 minutes, the carbon is saturated with hydrocarbons, and the VOC emission increases slightly.

The vacuum is applied to the filter and strips off the recovered VOC vapour from the carbon. The stripped off VOC vapour is then lead to an absorption column, where the VOC is condensed in a stream of gasoline. While one filter is being regenerated, the other filter is receiving the mixture of air and VOC vapour.

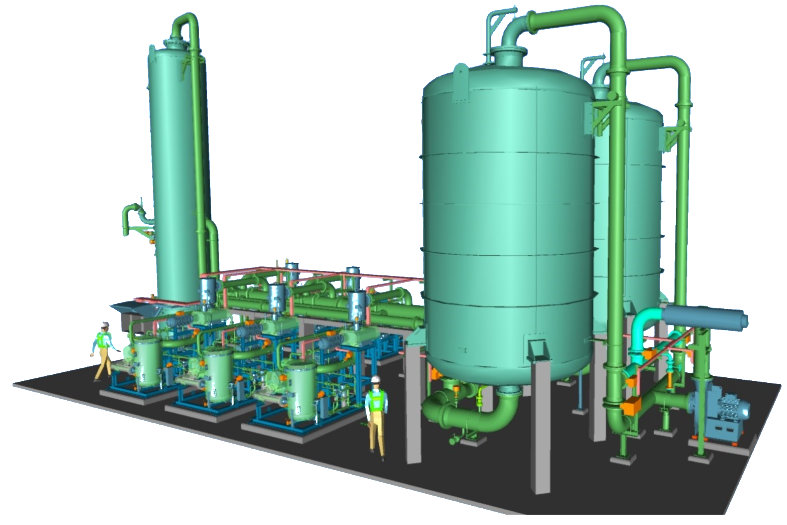

Assentech and VOCZero are your partner in Vapour Recovery (VRU) and Volatile Organic Compounds (VOC) Vapour Treatment.

We offer a range of Vapour Recovery Systems (VRU) for recovery of volatile organic compounds from vapours.

The process is based on the well-known technology of adsorption on activated carbon and regeneration of the activated carbon by vacuum. This technology has proven to be the best available for applications like storage, truck, rail, barge and ship loading operations.

The design and selection of parts are made to achieve a durable, safe and efficient process plant, and are based on international standards recognised in the oil and gas industry, such as ASME VIII, ASME B31.3, EN 60079 & EN 1127.

The VRU’s are designed to meet the stringent health and safety requirement set out by European ATEX and Machinery directives.

The typical vapours to be treated are:

• Petrol

• Diesel

• E5-E100 Gasohol (Ethanol)

• Methanol

• Benzene

• Toluene

• Xylene

• MTBE

• ETBE

• Naphtha

• Crude Oil

• Gas Condensate

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.