Industrial Hose Testing and Certification

Visual Inspection, Pressure Test, Elongation Test, Durometer Recordings, Electric Continuity Test and Certification

Experience and increased focus on due-diligence has reinforced the importance to Site Managers of the necessity to inspect, service and maintain their process equipment. Thus ensuring flawless operation and keeping the plant in tiptop shape which inevitably leads to a safer working environment.

Site hoses and cargo hoses should conform to recognised standard specifications, or as recommended by OCIMF.

Hoses should be of a grade and type suitable for the service and operating conditions in which they are to be used.

A single malfunction of a hose can have the following devastating impacts on the loading/unloading fluid transfer operation:

- Unplanned outages = money and time loss.

- Media spillage/leaks which can cause general danger to personnel and additionally lead to the pollution of the surrounding environment (not to mention the labour involved in any clean-up operation).

- The direct risk to the operators handling the loading/unloading/transfer operations (especially when handling corrosive and toxic substances).

To ensure the safe and efficient loading/unloading/transfer operations;

Assentech Rapid Response and Service Limited offer the following COMPREHENSIVE INDUSTRIAL HOSE TESTING & CERTIFYING SERVICE in accordance with the maintenance and test regime specified by OCIMF AND ISGOTT.

Hoses in service will have a documented inspection at least annually to confirm their suitability for continued use. This includes:

- A visual check for deterioration/damage; where our competent engineer examines:

- The hose assembly for irregularities in the outside diameter.

- The hose cover for damaged or exposed reinforcement or permanent deformation.

- The end fittings for signs of damage, slippage or misalignment

- Pressure Test (Integrity Check): Hose assemblies will be hydrostatically examined to check their integrity (leakage, movement of end fittings etc.)

- Electrical continuity test: to test the electrical bond between the end fittings of a hose assembly to prevent a static electricity build-up within the length of the hose.

- Certification: Individual certificates detailing the results and any advisories are produced for the customer to associate with their Asset Management systems.

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.

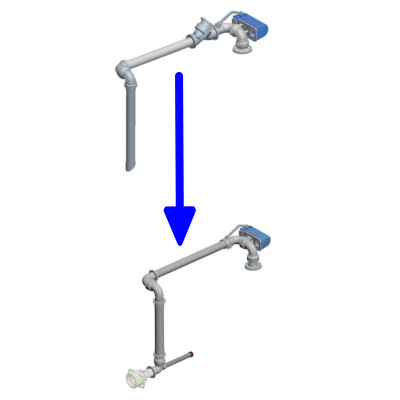

We supply a broad range of loading equipment and complete loading platforms, gantries and racks.