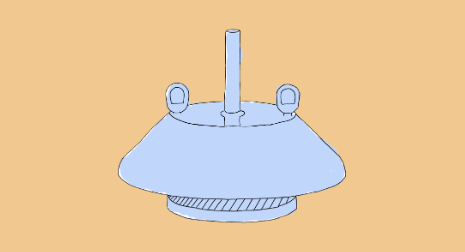

Flame arresters are specialised mechanical devices designed to permit the flow of air or fluid while preventing the progression of a flame. They are strategically installed to halt the movement of flames through pipelines (in-line) and into containers (end-of-line). Their operation hinges on two key principles: firstly, they eliminate the oxygen within a flame, effectively extinguishing it, and secondly, they reduce the flame’s temperature below its auto-ignition point. Flame arresters are indispensable in environments where flammable liquids and gases are prevalent. This includes but is not limited to, fuel terminals, chemical plants, distilleries, and pharmaceutical plants.

Flame arresters play a crucial role in limiting the damage caused by ignition. They can inhibit a fire from spreading from one area of a facility to another and prevent a flame from penetrating a vessel and igniting vapour. These devices are designed to curb flame propagation in gas piping systems and safeguard low-pressure tanks containing flammable liquids. By protecting low flash point liquids from external heat and ignition sources, flame arresters enhance fire protection and safety.

Types of Flame Arresters we Supply

- Deflagration Flame Arresters: Deflagration describes a subsonic combustion process that propagates through heat transfer, where hot burning material heats the next layer of cold material and ignites it. This type of combustion is commonly observed in everyday fires and explosions.

- Detonation Flame Arresters: Detonation, on the other hand, is a supersonic combustion process that propagates through shock. It involves a supersonic exothermic front accelerating through a medium that eventually drives a shock front propagating directly in front of it. Detonations are typically observed in conventional solid and liquid explosives, as well as in reactive gases. Gaseous detonations usually occur in confined systems but can occasionally be observed in large vapour clouds. They are often associated with a gaseous mixture of fuel and oxidant of a composition slightly below conventional flammability limits.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation/Certification List

Individual Documentation/Certification can be requested from the following list as applicable

- API2000 Production Functionality Test Report to section 5.4 including Set pressure and leak rate with traceability to EN 10204.3.1. Not available for spare parts

- Volume Leak Rate Test report at customers specified operating pressure between 65% < 90% of set point. Suitable for LDAR reporting.

- Pre-Commissioning Safety and Functionality Report

- Emissions Quantification LDAR Survey and report on installed valves

- Facilitating Inspection and/or witness test

- Certificate of Conformance

- GA Drawing & Parts List for Information

- Certified Drawings

- Material Test Report acc to EN 10204.3.1

- Certificate of Origin (if required - attested by Local Chamber of Commerce).

- Inspection and Test Plan (ITP).

- Manufacturer Record Book

- Works Inspection Certificate 3.1

- Material Inspection Certificate 3.1

- Casing Pressure Test for Integrity

- Installation & Operation Manual

- ATEX certificate of conformity

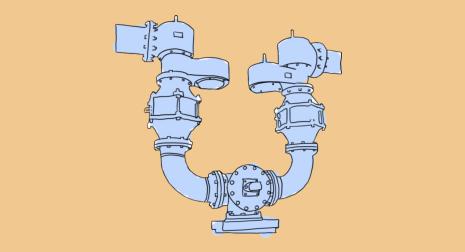

End-of-Line vs. In-Line Flame Arresters

The difference between End-of-Line and In-Line Flame Arrester products is defined by ISO 16852.

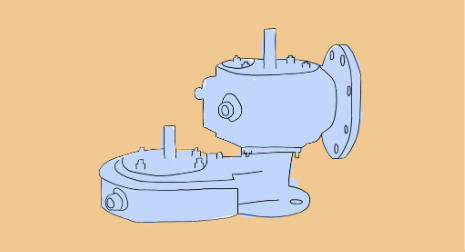

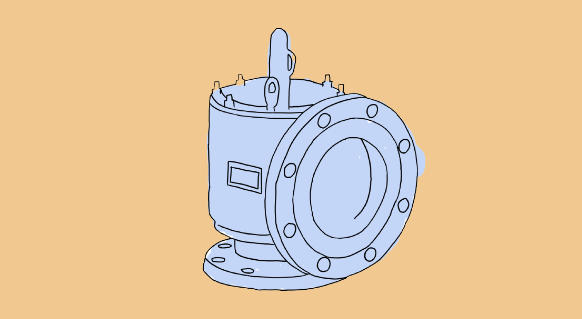

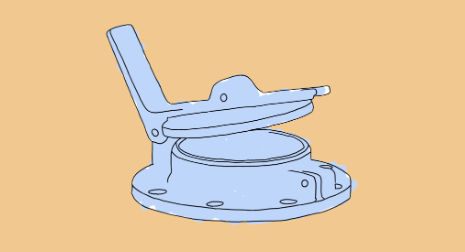

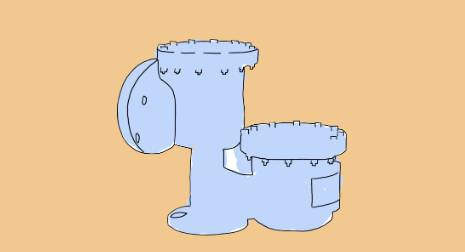

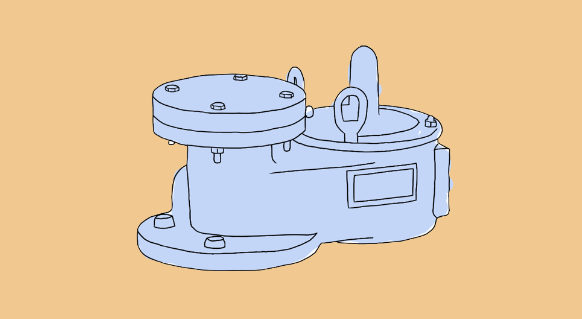

End-of-Line Flame Arrester (ISO 16852 section 3.21): This type of flame arrester is fitted with one pipe connection only. Eccentric

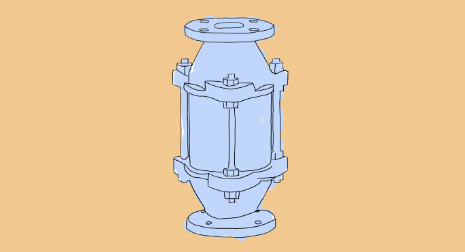

In-Line Flame Arrester (ISO 16852 section 3.22): This type of flame arrester is fitted with two pipe connections, one on each side of the flame arrester. Concentric

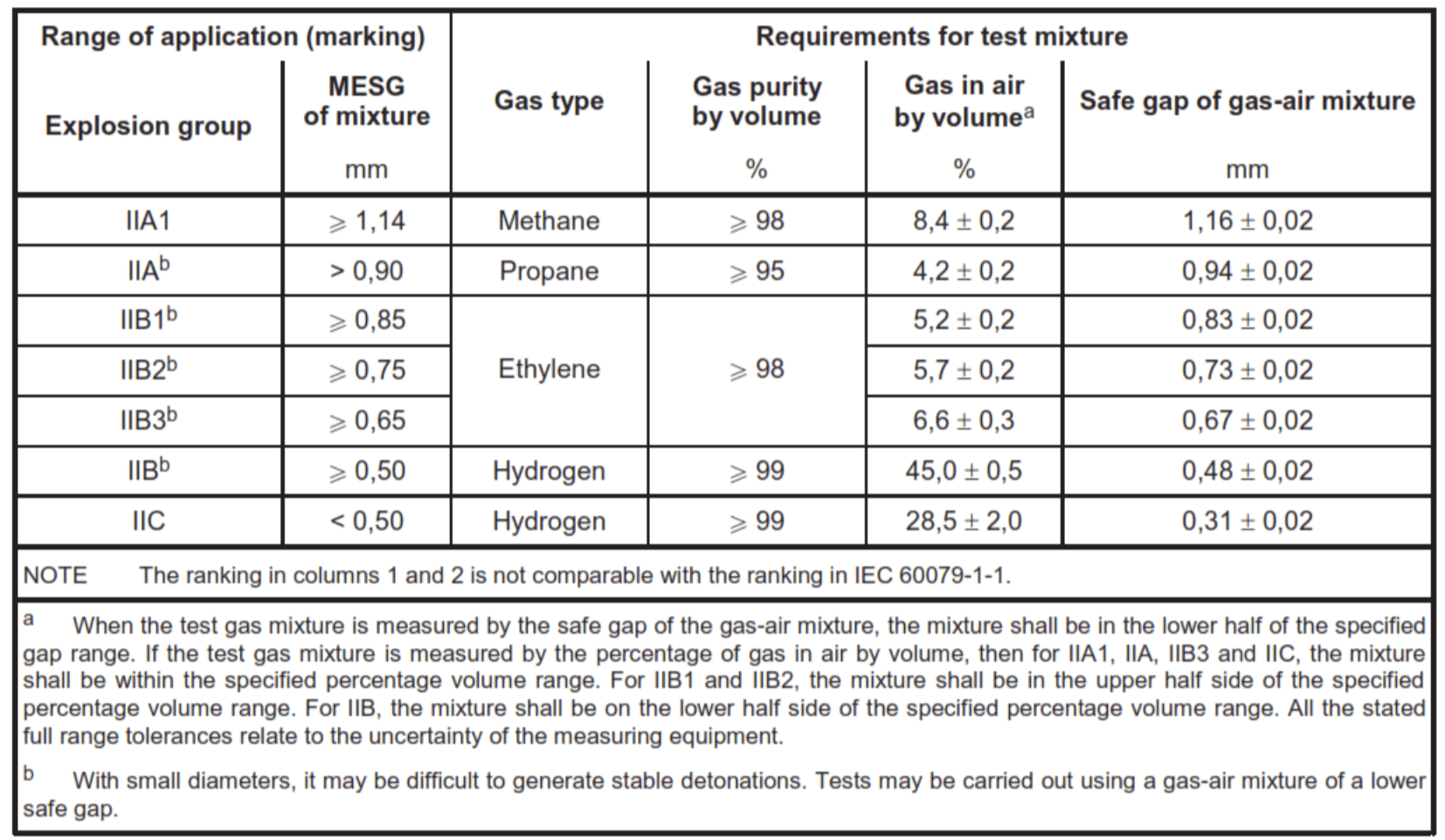

Specification of Gas-Air Mixtures for Deflagration and Detonation Tests. This comprehensive diagram illustrates the diverse Gas Groups associated with Flame/Detonation Arresters, providing a clear guide to understanding the varying parameters for effective flame and detonation control in different gas environments. Ensure optimal safety and performance by choosing the appropriate Flame Arrester for your specific gas group.

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

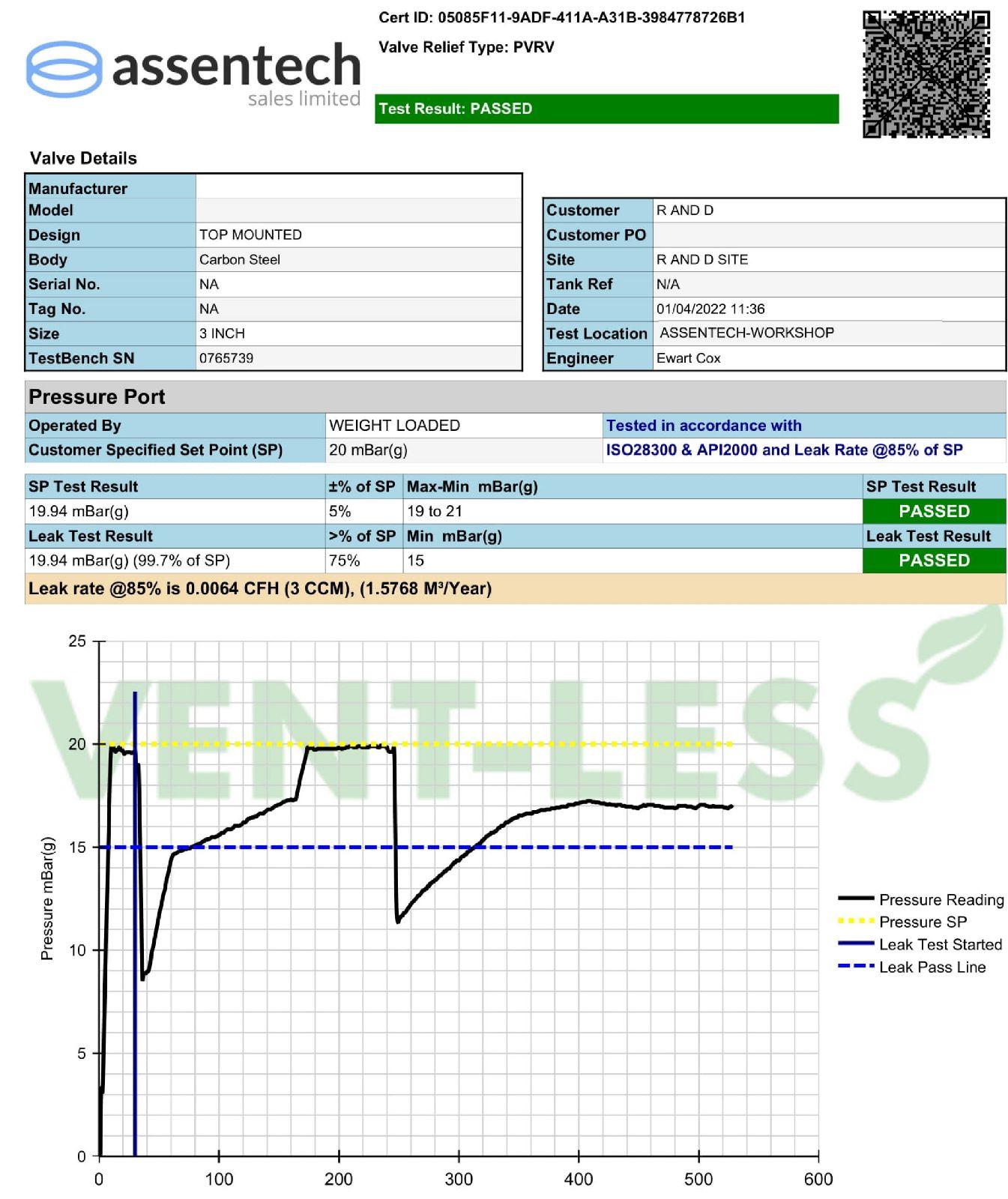

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.

Venting Equipment Product Range

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Assentech Academy - Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact