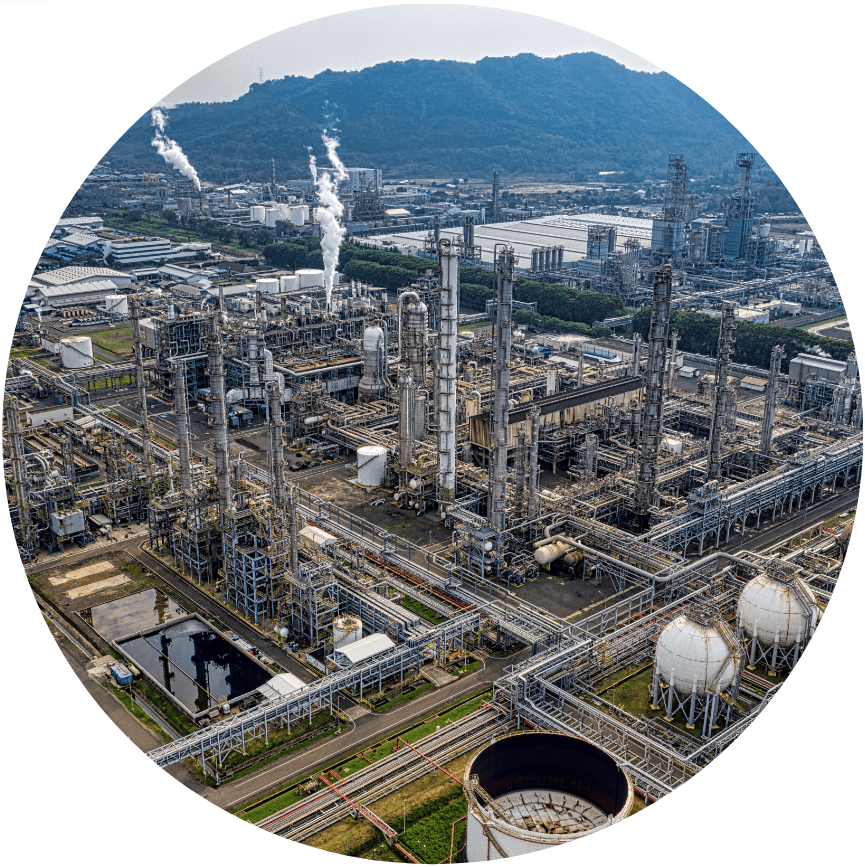

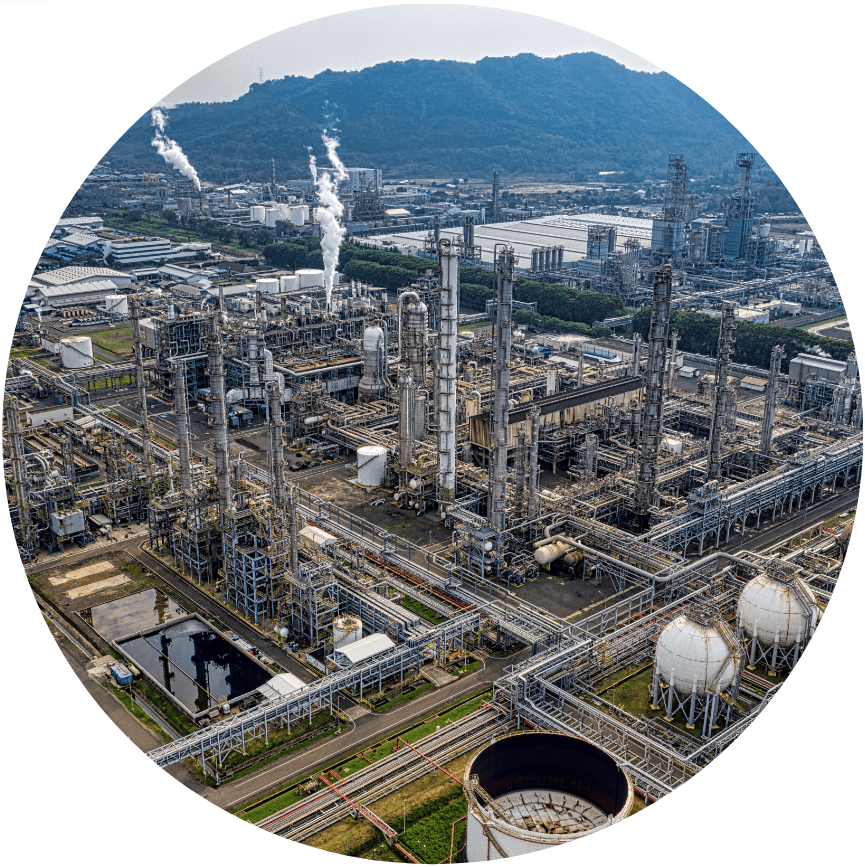

With an enviable reputation in tank storage knowledge and technical expertise, tank breather valves have always been a core product supply for Assentech. With increased focus on the environment and the risks associated with emissions from the biogas and chemical industries, our mission is to support operators with measuring, monitoring and reducing plant emissions to demonstrate best practices, and evidence a duty of care to the workforce and environment. By using a Best Available Technique (BAT) to identify leak points, ie, breather valve leakage, is key criterion for Regulation 61 compliance and supporting the biogas industry to reach Net Zero. The failure to mitigate risks impacts so many departments of any business, ie, legal, quality, environmental, engineering, procurement, finance and insurance.

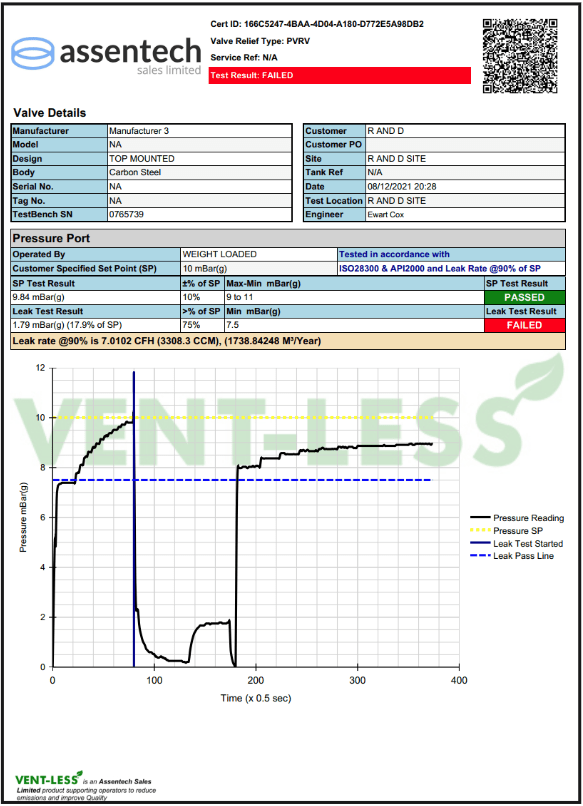

Over 80% of the valves installed from new or maintained at tank storage facilities have not been supplied with a leak test certification and aligned to the international standards – API2000 / ISO 28300. It’s not surprising that environmental breaches, criminal investigations and litigation claims have increased for excessive emissions and the failure by tank storage facilities to mitigate risk and demonstrate a responsibility to prevent exposure.

With individual breather valves being uncertified (ie not tested in accordance to the test protocol of API2000), valves leaking at the digester’s operating pressure ranges from 4-50 cubic feet per hour (CFH) you can understand the impact this is having on operating profits, the environment and the health staff and neighbours working in close proximity to the site. Please take a look at our emission calculation programme below to understand the financial, environmental and safety risks associated.

“Evidence your Duty of Care and Corporate Social Responsibility by using these vital measurables for ESG and Environmental Reporting”

The Environment Agency, ADBA and many other committees and organisations routinely request input from Assentech in the development of best practice guidance for operators in the tank storage and biogas industries.

Our Service Engineers have amassed an extensive array of knowledge and practical experience dealing with a diverse range of breather valve applications. This spans from biogas digesters and chemical storage facilities to pharmaceutical operations and oil and gas industries. We boast a profound understanding of the entire application spectrum, recognising the implications of fill/empty rates and the accurate designation of valve set pressures. Our expertise enables us to optimise operating pressures and curtail emissions, thereby ensuring the maximum efficiency and sustainability of your operations.

Emissions Case Study

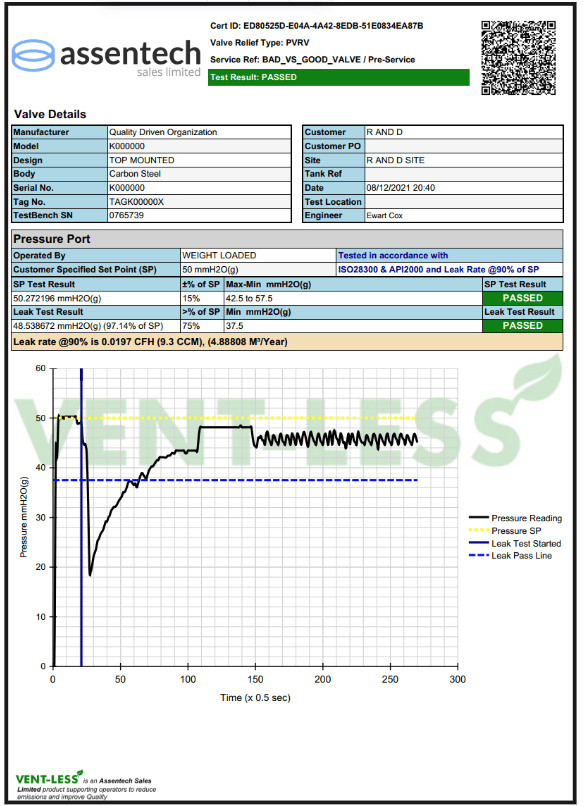

We can supply, test and calibrate valves that will keep your Biogas facility safe, compliant and profitable by ensuring valves are individually tested on the pressure and vacuum ports and meet the acceptable leakage rate to less than 0.1 CFH.

To demonstrate both the financial and environmental impact of breather valve leakage, our Engineers recently attended a biogas facility and reduced leakage/emissions from one 12” breather valve from 161 tonnes GWP to just 158 kg per year (equivalent to 118 double-decker buses to 11% of one) by using best available techniques of ageing plant.

By purchasing through us, you have complete peace of mind knowing you have procured an asset that will protect yourself, your facility and our environment attributing to your Net Zero journey whilst maximising profitability and demonstrating your duty of care.

Our Guarantee

- Minimise harmful vapour emissions for a cleaner atmosphere.

- Enhance your business profitability through extended lifespan, reduced downtime, improved sealing.

- Foster healthier workspaces for your employees to prevent litigation claims.

- Optimise nitrogen usage to promote sustainability and improve profitability.

- Retain valuable, toxic and flammable substances within your tanks effectively.

- Safeguard the environment and local communities from potential hazardous, toxic, and combustible emissions.

- Ensure total adherence to international standards for seamless operation.

- Supply comprehensive, documented proof of optimal functional performance.

- Offer industry-leading technical advice tailored to your needs.

- Assist in maintaining cordial relations with regulatory bodies.

- Collaborate closely with our clients to develop customised plans that envisage a prosperous future

We Won’t

- Compromise on product quality for optimal safety and adherence to regulations

- Ignore the varied performance across different tank valves

- Promote cheaper alternatives which often lack individual leakage or API2000 capacity testing

- Ignore the potential risks associated with inferior quality valves on expensive processes

- Put a price on environmental health, staff safety, and neighbour well-being

- Stop pushing for high-quality valves with regular servicing, providing long-term value exceeding initial savings on cheaper devices

- Promote batch certification of multiple devices which isn’t sufficient.

Our Guarantee

- Minimise harmful vapour emissions for a cleaner atmosphere.

- Enhance your business profitability through extended lifespan, reduced downtime, improved sealing.

- Foster healthier workspaces for your employees to prevent litigation claims.

- Optimise nitrogen usage to promote sustainability and improve profitability.

- Retain valuable, toxic and flammable substances within your tanks effectively.

- Safeguard the environment and local communities from potential hazardous, toxic, and combustible emissions.

- Ensure total adherence to international standards for seamless operation.

- Supply comprehensive, documented proof of optimal functional performance.

- Offer industry-leading technical advice tailored to your needs.

- Assist in maintaining cordial relations with regulatory bodies.

- Collaborate closely with our clients to develop customised plans that envisage a prosperous future

We Won’t

- Compromise on product quality for optimal safety and adherence to regulations

- Ignore the varied performance across different tank valves

- Promote cheaper alternatives which often lack individual leakage or API2000 capacity testing

- Ignore the potential risks associated with inferior quality valves on expensive processes

- Put a price on environmental health, staff safety, and neighbour well-being

- Stop pushing for high-quality valves with regular servicing, providing long-term value exceeding initial savings on cheaper devices

- Promote batch certification of multiple devices which isn’t sufficient.

“All of our parts are sourced from quality suppliers, instrumentation is guaranteed for accuracy offering full traceability to national standards 9001”

Get in Contact with the team to discuss your organisation’s needs