Heavy Duty Aluminum Skin and Pontoon Internal Floating Roof

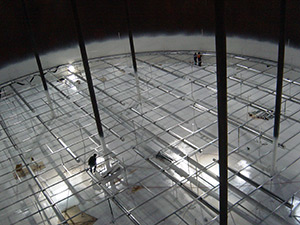

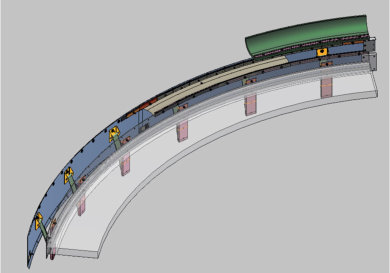

The Matrix Applied Technologies heavy-duty Internal Floating Roof comprises 5 core elements, a central frame, a deck, pontoons, landing legs and rim seal. The deck sits on top of the pontoons which allow it to float clear of the product surface. When the tank is emptied, the IFR lowers onto legs which prevent it from fouling on the tank floor or in-tank equipment such as inlets and stirrers.

When investing in an IFR, there is never 100% certainty of what the future holds for the tank. It may in the future be subject to a change of duty, be modified or require additional gauge poles and these factors need to be considered on purchase. Many of the IFR’s offered by our competitors have structural integrity which relies upon the collective strength of the integral components. This is not a long term solution as it makes future repairs or modifications impossible – after all, you should be able to change your windows at home without the house falling down.

The Matrix Applied Technologies Heavy Duty pontoon type IFR is different – the strength core is provided by a rigid central frame, to which the pontoons, landing legs, rim seal and deck are fastened. This means that in years to come, repairs or modifications can be made to the deck, pontoons or seal without requiring total replacement of the IFR.

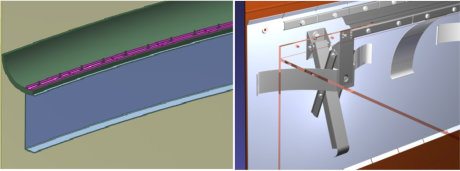

This is not the only part of the design where Matrix Applied Technologies think differently – for instance – Matrix Applied Technologies floatation pontoons are hung below the deck on custom-designed straps which spread stress evenly over the pontoon, making it independent of the structure. Many competitor designs incorporate the pontoon within the structure – this is a shortcut because although it means less metal and less cost up front, pontoons are not a structurally able to cope with cycling stresses and almost always result in cracking of the ends. This leads to leaking pontoons, a sinking deck and problems with de-gassing.

These are just two design choices which set Matrix Applied Technologies apart. There are many other which we would happy to discuss including;

- Heavy duty as standard – sturdier construction than most other types

- Landing Legs are not connected to the pontoons

- Easy assembly – quicker and cheaper installation

- Extruded rim allows fitting a shoe seal without rim reinforcement

- Coil type anti-static/earth connection eliminates fouling problems

- Heavy duty Shoe seal offered as standard (other seal types available on request)

- Deck sheeting is fastened from the top making it accessible and easy to modify in the future

- 0.6mm (0.024”) thick main deck sheeting as standard – it will not puncture or tear easily

- All fasteners are stainless steel

- 1000lb/ft² load capability – the majority of decks will just about cope with the API standard of 500lb/ft2

- We can coat and anodise our IFRs to suit your particular requirement

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.