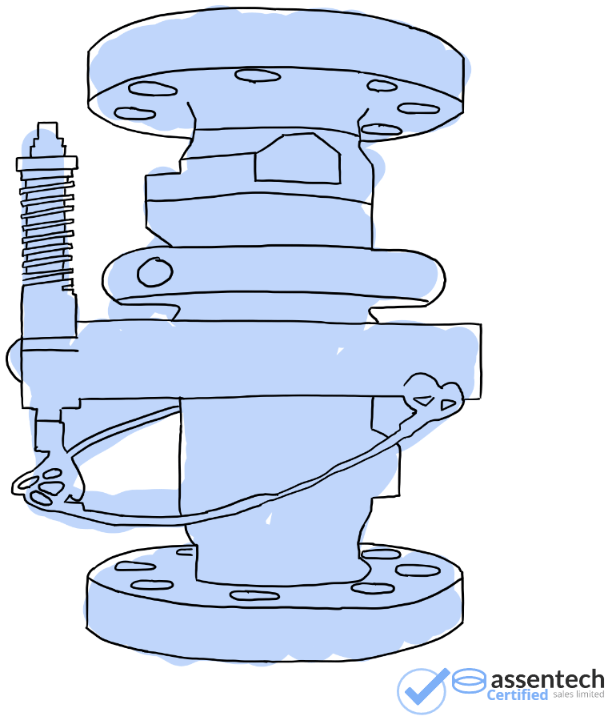

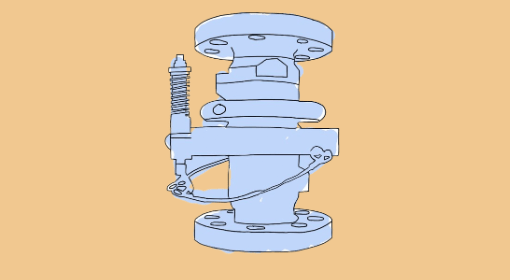

Break-away Couplers, also known as Emergency Release Couplers, are fundamental components in fluid transfer systems, designed to prevent hazardous spills and protect equipment from damage in the event of accidental drive-away or brake failure during loading operations. These devices are commonly used in locations like fuel and chemical terminals, distilleries, and gas terminals where fluid transfer lines could be at risk. They operate by separating into two halves when exposed to certain forces, causing valves to shut off and effectively stop the flow of fluid. This mechanism ensures safety and mitigates risks associated with human errors.

Assentech Sales Limited is a trusted supplier of these couplers, backed by a wealth of expertise derived from robust testing programs and field experience. Beyond providing high-quality couplers, we assist our customers in gantry stiffening, coupler installation, and product selection, tailored to individual application needs and preferences. It is worth noting that the choice of coupler, Break-away or Emergency Release, depends largely on application specifics and customer preference. The couplers we offer boast of an intelligent design that ensures 100% instant double valve shut-off, thus providing reliable product transfer protection in diverse and demanding conditions.

Types of Break-away Couplers we Supply

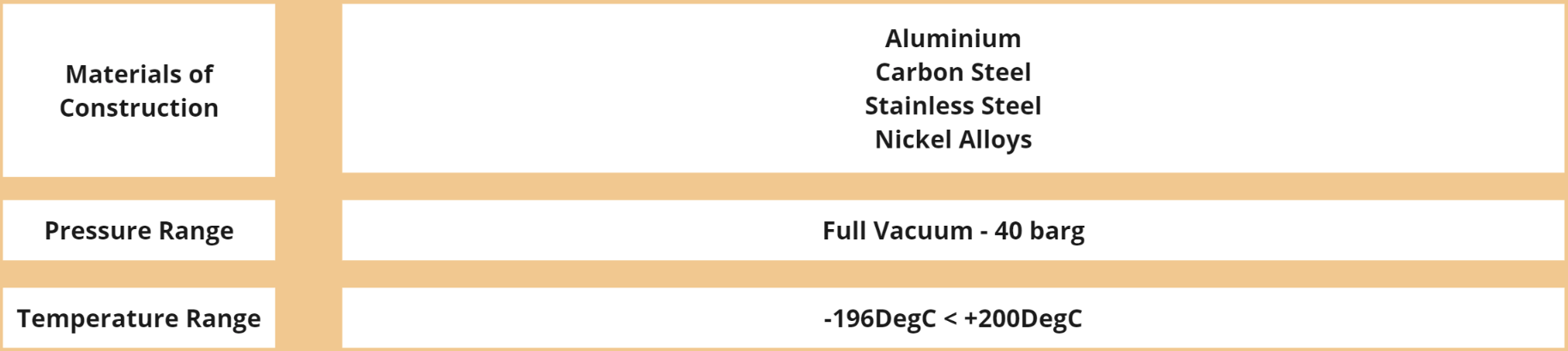

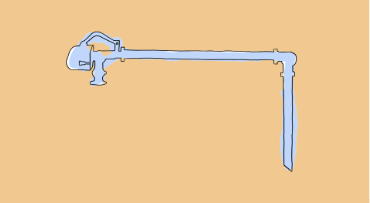

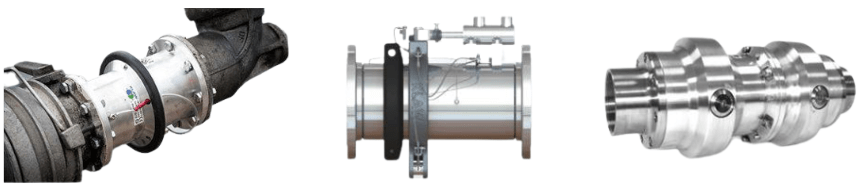

- Non-Cryogenic Industrial Break-away Coupling : With their unique design that activates under a bending moment at angles from zero to 90 degrees, offer unparalleled versatility and adaptability for all industrial product transfer installations due to their infinite material selection.

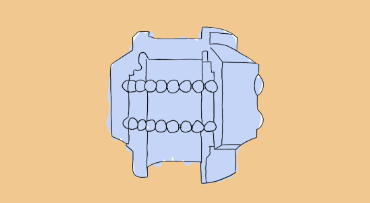

- Cryogenic Industrial Break-away Coupling : Featuring an innovative design that activates under a bending moment from zero to 90 degrees, offer proven reliability and versatility for a wide range of applications, including LNG transfer solutions and handling of substances like Liquid Oxygen, Ethylene, and Ethane, even under extreme temperatures down to -196°C (-320°F).

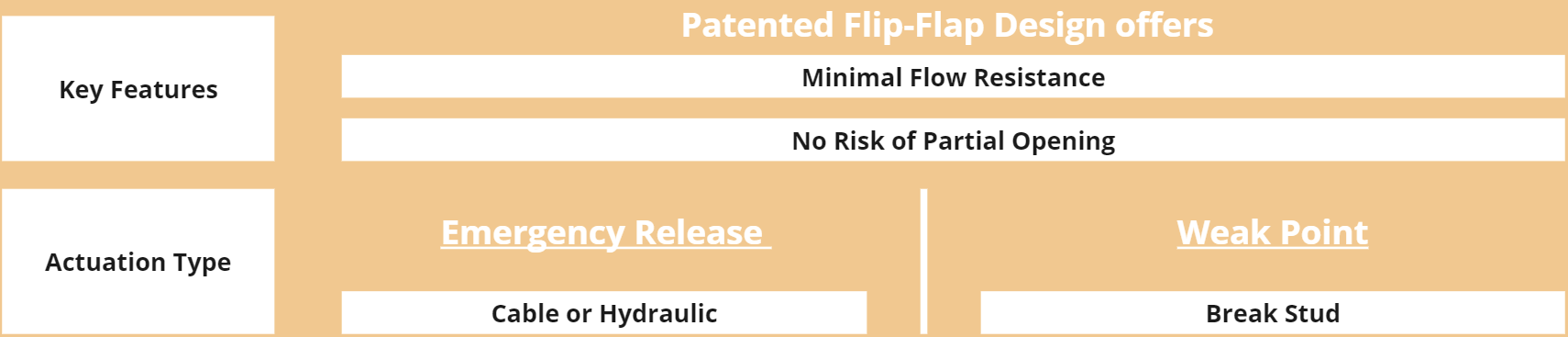

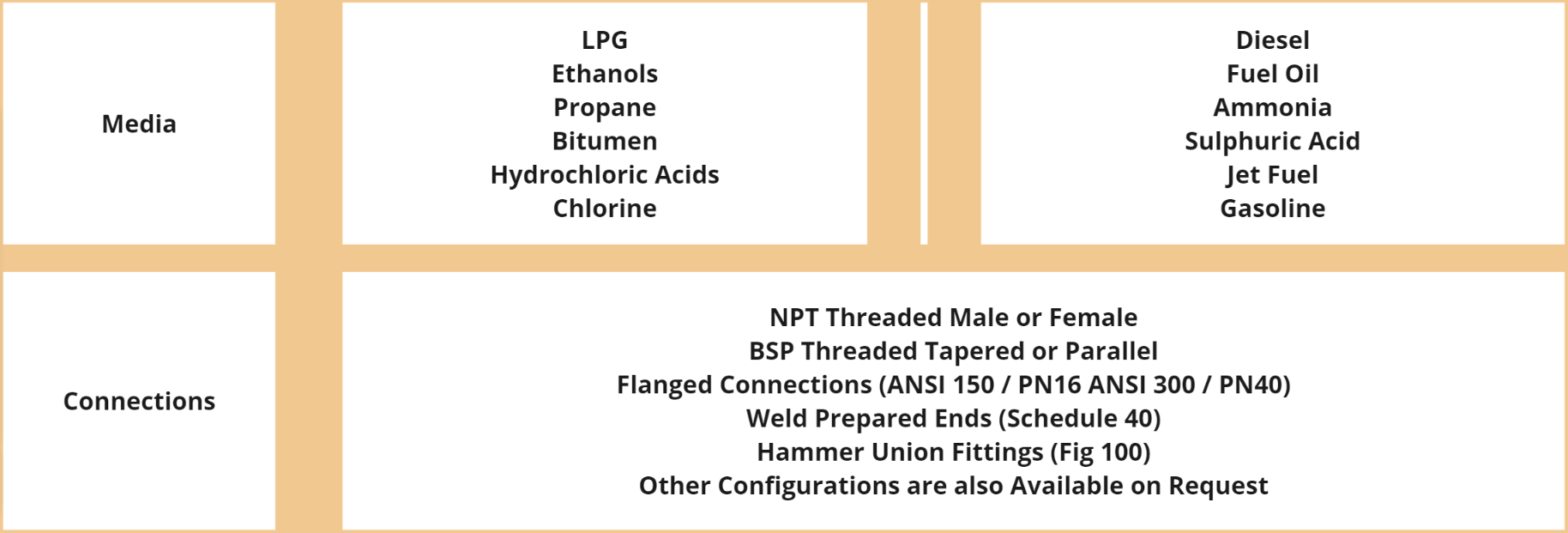

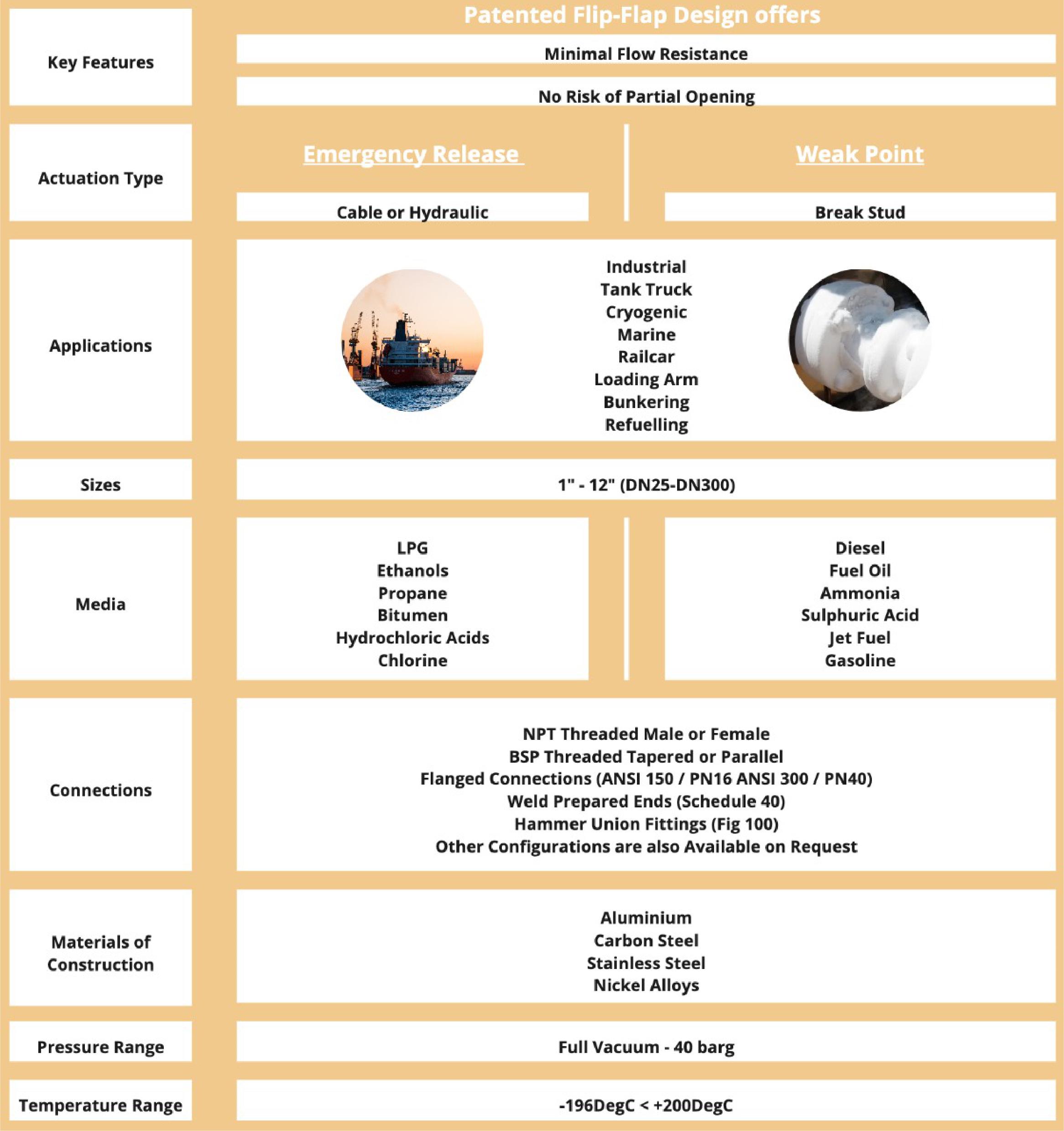

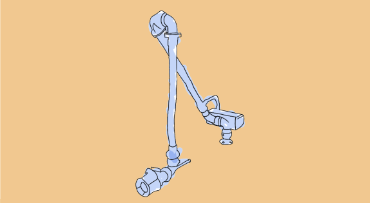

- Non-Cryogenic Emergency Release Coupling: Employ Flip-Flap technology for controlled separation of the halves using cable, hydraulic, or dual release systems, reducing stress on media transfer systems, with wide usage in LPG, fuel, and chemical transfer installations, offering optimal flow rate and closure solutions, with the choice of release method tailored to individual needs for enhanced safety and reliability.

- Cryogenic Emergency Release Coupling: Leverage Flip-Flap technology for controlled activation through cable, hydraulic, or dual release systems, providing a safe, reliable solution for cryogenic transfer applications such as bunkering, refuelling, and loading arms, with comprehensive on-site testing for the highest safety standards and versatile installation methods tailored to suit specific client requirements.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

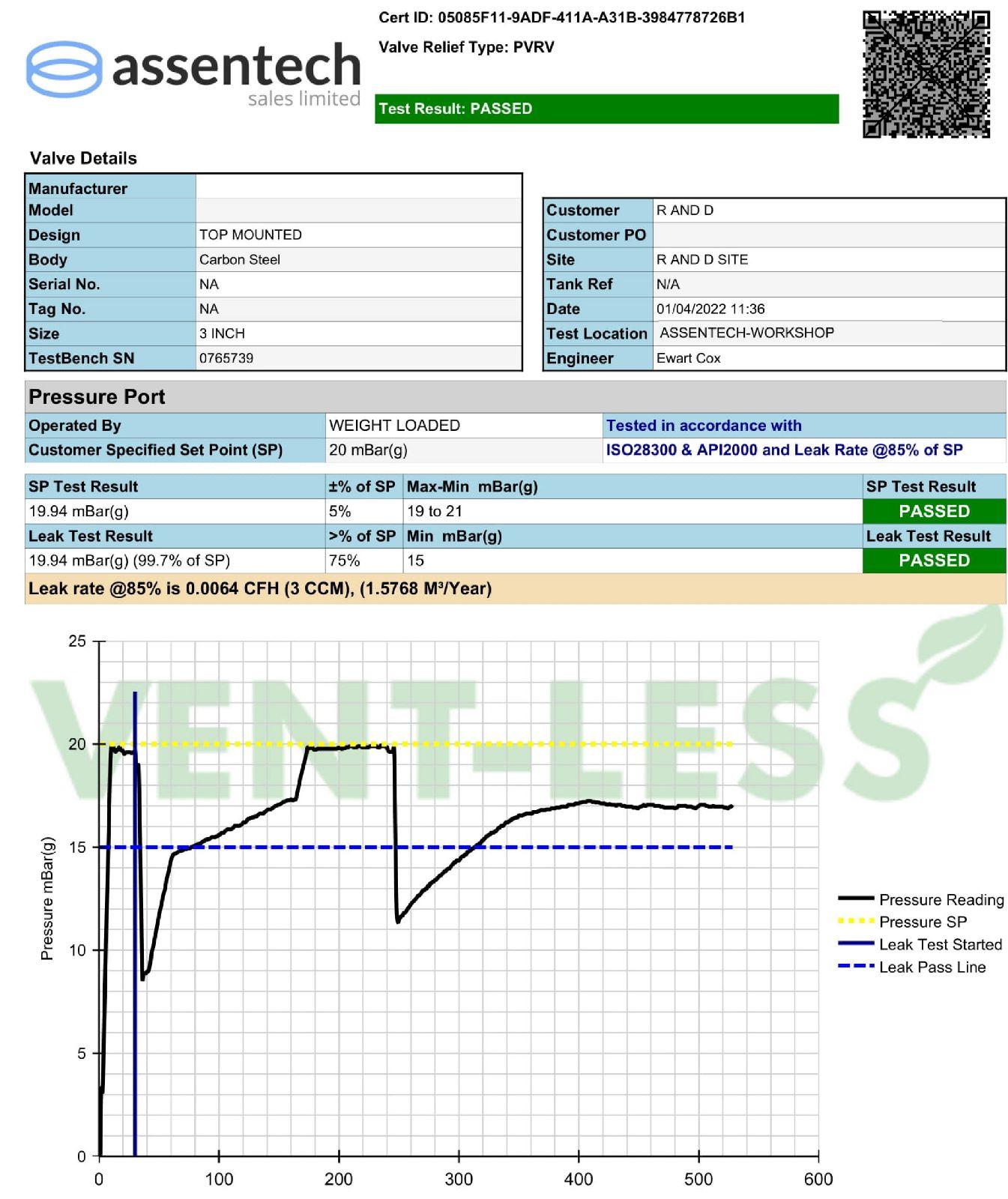

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

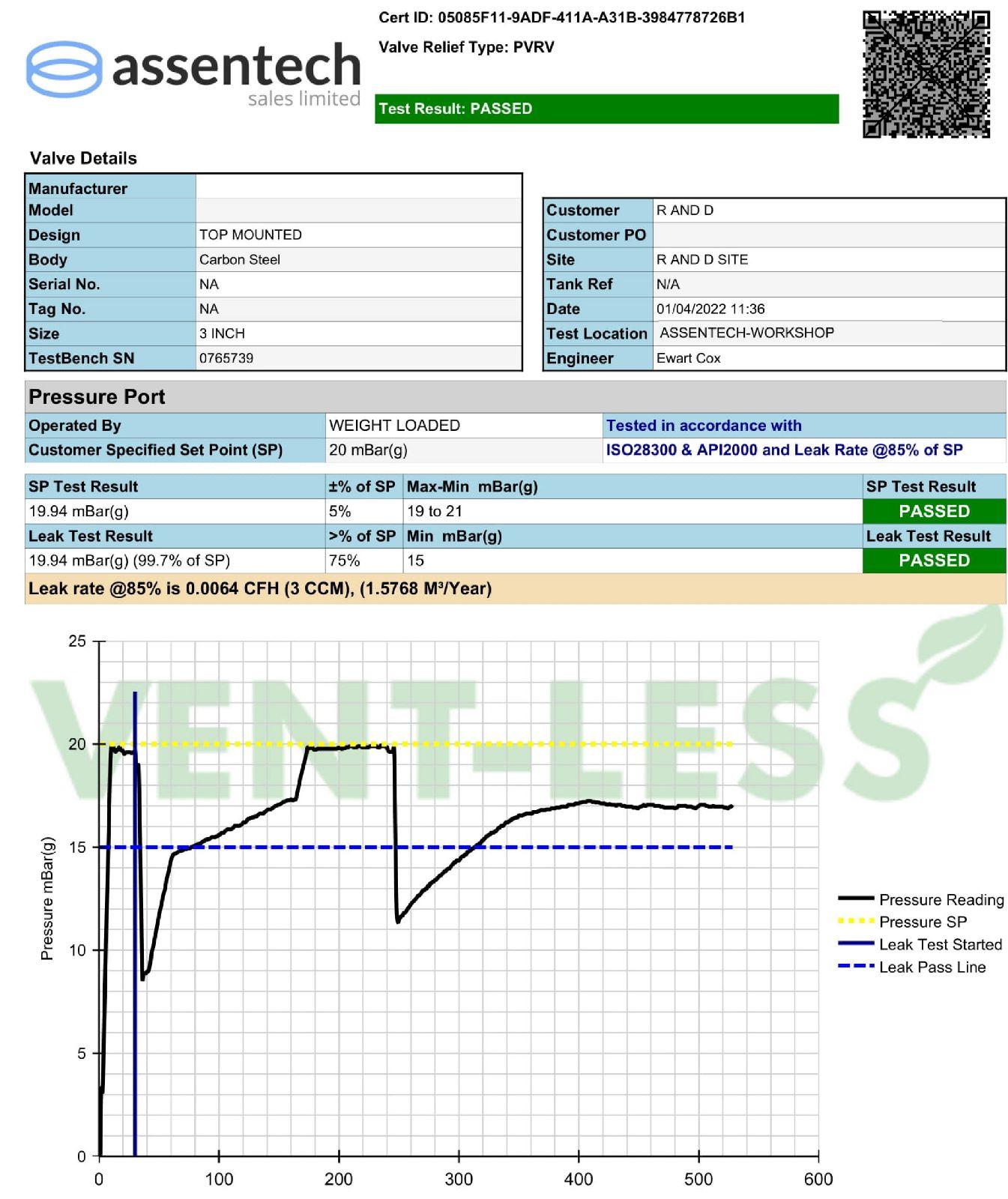

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Top Loading Arms

Swivels

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact