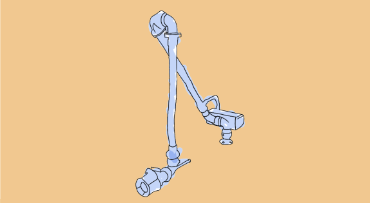

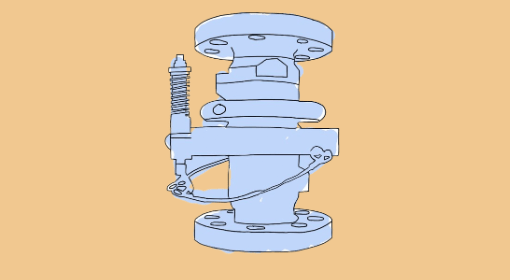

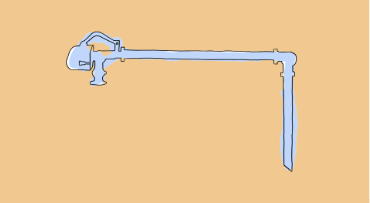

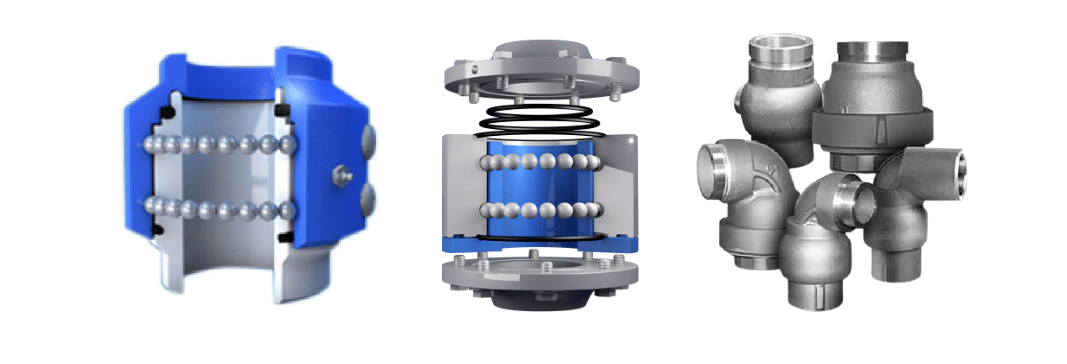

At Assentech, we proudly distribute OPW’s wide range of swivel joints, extensively employed across numerous industries including chemical, petroleum, petrochemical, refining, mining, distilling, brewing, as well as ink and paint sectors, not forgetting farm irrigation and fertilisation. Design, plant, and maintenance engineers commonly utilise OPW’s swivel joints in applications such as flexible piping systems, loading arms, hose reels, sewer rodding, and wastewater treatment equipment, among various types of process machinery. Their use extends to machine tool coolant transfer, drum filling tasks, and a multitude of in-plant fluid and dry bulk transfer applications.

The key to OPW swivel joints is their versatility. They facilitate the use of rigid metal piping for the loading and unloading of fluids and dry products under pressure or vacuum, removing the complications or risks associated with managing hefty, unwieldy hoses.

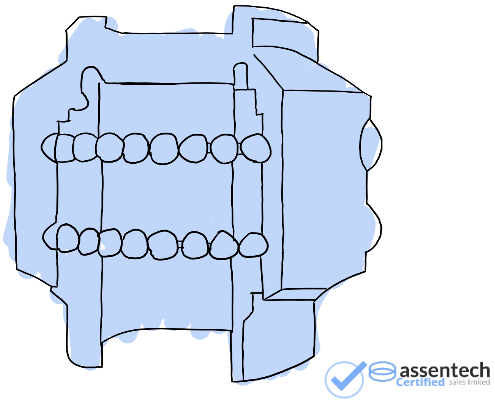

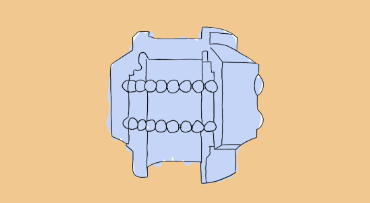

Noteworthy features of Swivel Joint Design include:

- Secure Seals

- Shielded Bearing Chamber

- Long-lasting Bearings

- Straightforward Lubrication

- Absence of Field Adjustment

- Safety-oriented Design

OPW swivel joints are durable, reliable, and easy to operate and maintain. They are available in a wide range of materials, including stainless steel, cast steel, fabricated steel, ductile iron, aluminium or bronze, enabling us to cater to your most stringent specifications. We also have special capabilities, such as split flange, jacketed, lined, and coated designs.

Types of Swivel Joints we Supply

- General Purpose Swivel Joints – 3000 Series: Offering a vast selection of materials such as Aluminium, Bronze, Carbon Steel, and more, with sizes from 3/4″ to 12″, a variety of seals, and multiple end connection options, our product range caters to almost any application need.

- 8000 Series Endura Split Flange Swivels: Designed for transferring hazardous materials like acids, solvents, and petrochemicals, sets the standard in Loading Arm Swivel performance, offered in standard sizes of 2, 3, and 4 inches, various materials and seals, and multiple end connection options.

- Hose Reel Swivel: Integral to many hose reel applications, come in a range of designs specifically for Hose Reels, with customisation options available to suit specific application requirements.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

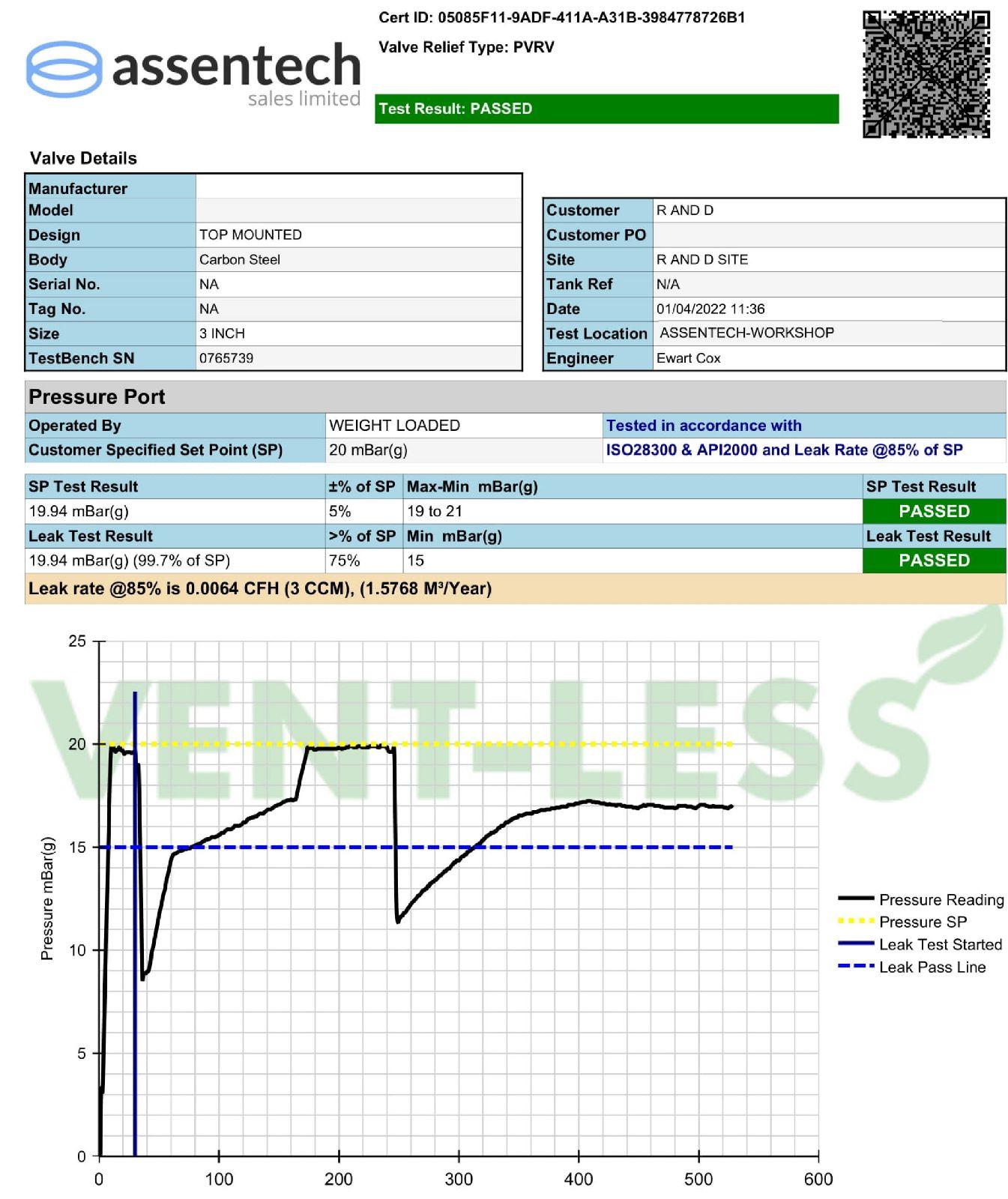

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

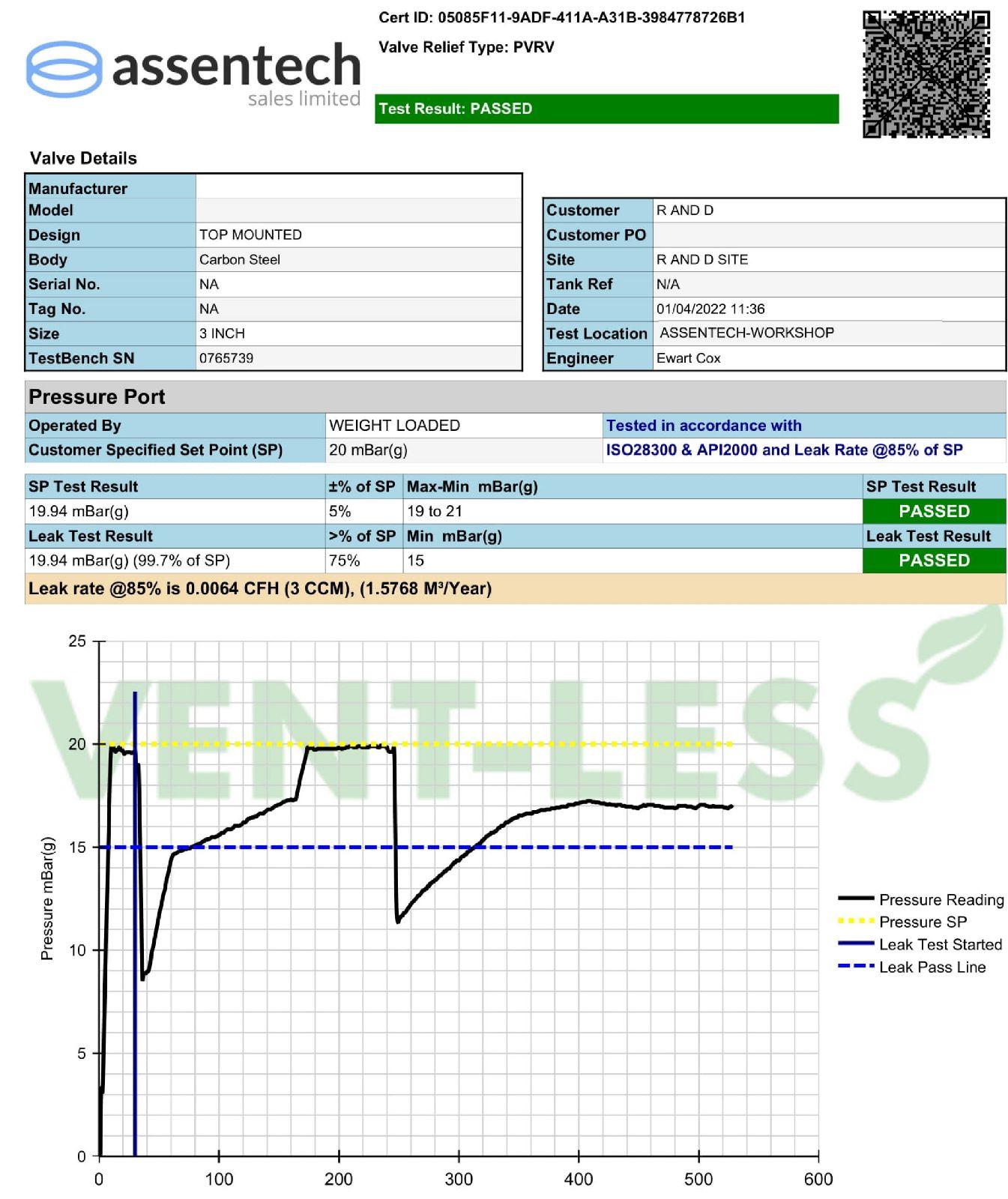

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Top Loading Arms

Swivels

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact