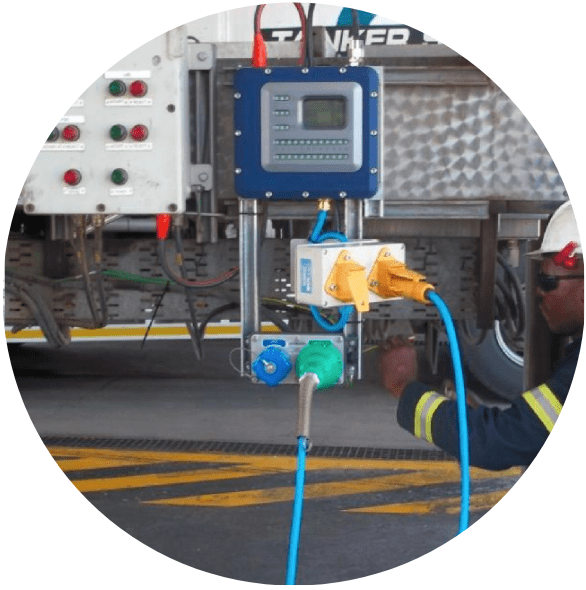

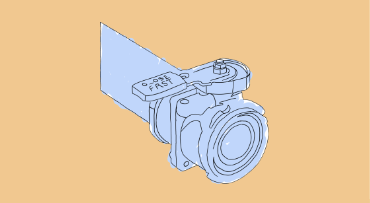

At Assentech Sales Limited, we are proud to offer the OPW Model 3205E ROM (Retain Overfill Monitoring) system. This advanced secondary overfill prevention solution is designed specifically for tank truck loading operations. The system not only monitors retained product, but also provides indicators for wet/dry conditions, wire short cuts, grounding conditions, and shorted sensors, using LED indicators and a separate display for clear and immediate status updates.

Since the shift from top to bottom loading in the early 1980s, ‘rack’ monitors like the OPW Model 3205E ROM have become commonplace in tank loading bays around the world. This transition to bottom loading has revolutionised safety levels during tanker filling by eliminating the risks associated with working at height, exposure to volatile organic compounds (VOCs), and flashover. The term ‘rack monitor’ is a general term for ground verification overfill monitors that are designed to comply with EN 13922 standards. As a trusted intermediary, we ensure you receive this high-quality equipment to enhance the safety and efficiency of your operations.

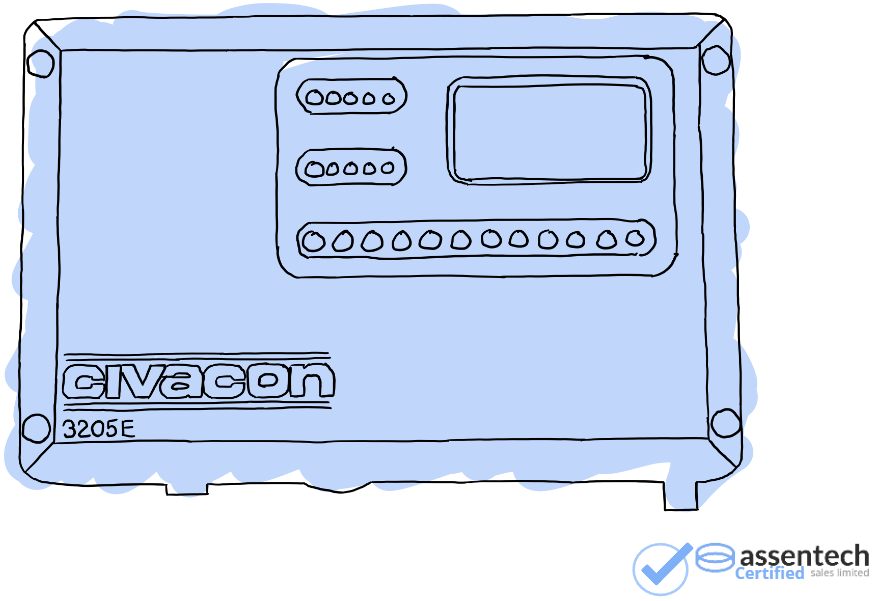

- Complies with ATEX standards

- Combines compartment empty and overfill detection into a single unit

- Interoperable with all standard industry sensors and rack monitors

- Includes a safety feature that prevents loading from proceeding without activating the reset circuit after system alerts

- Features a reset circuit specifically for bottom sensors

- Equipped with a bottom retain sensor override timer that cancels override timing when the plug is removed from the socket

- The ROMII Plus monitor, if connected, automatically closes bottom valves for added security

- Supports up to 8 compartment tankers using 2-wire optic overfill and bottom sensors

- Can accommodate up to 12 compartments using 5-wire optic overfill sensors

- Automatically configures the number of installed sensors at the time of installation

- Includes a timer with a progress indicator infrared function key

- Provides individual LED indication for each input device

- Displays LED indication for each compartment and status symbols

- LED socket connection status ensures proper connection

- Operates in a wide temperature range from -40°C to + 70°C

- Complies with ATEX standards

- Combines compartment empty and overfill detection into a single unit

- Interoperable with all standard industry sensors and rack monitors

- Includes a safety feature that prevents loading from proceeding without activating the reset circuit after system alerts

- Features a reset circuit specifically for bottom sensors

- Equipped with a bottom retain sensor override timer that cancels override timing when the plug is removed from the socket

- The ROMII Plus monitor, if connected, automatically closes bottom valves for added security

- Supports up to 8 compartment tankers using 2-wire optic overfill and bottom sensors

- Can accommodate up to 12 compartments using 5-wire optic overfill sensors

- Automatically configures the number of installed sensors at the time of installation

- Includes a timer with a progress indicator infrared function key

- Provides individual LED indication for each input device

- Displays LED indication for each compartment and status symbols

- LED socket connection status ensures proper connection

- Operates in a wide temperature range from -40°C to + 70°C

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

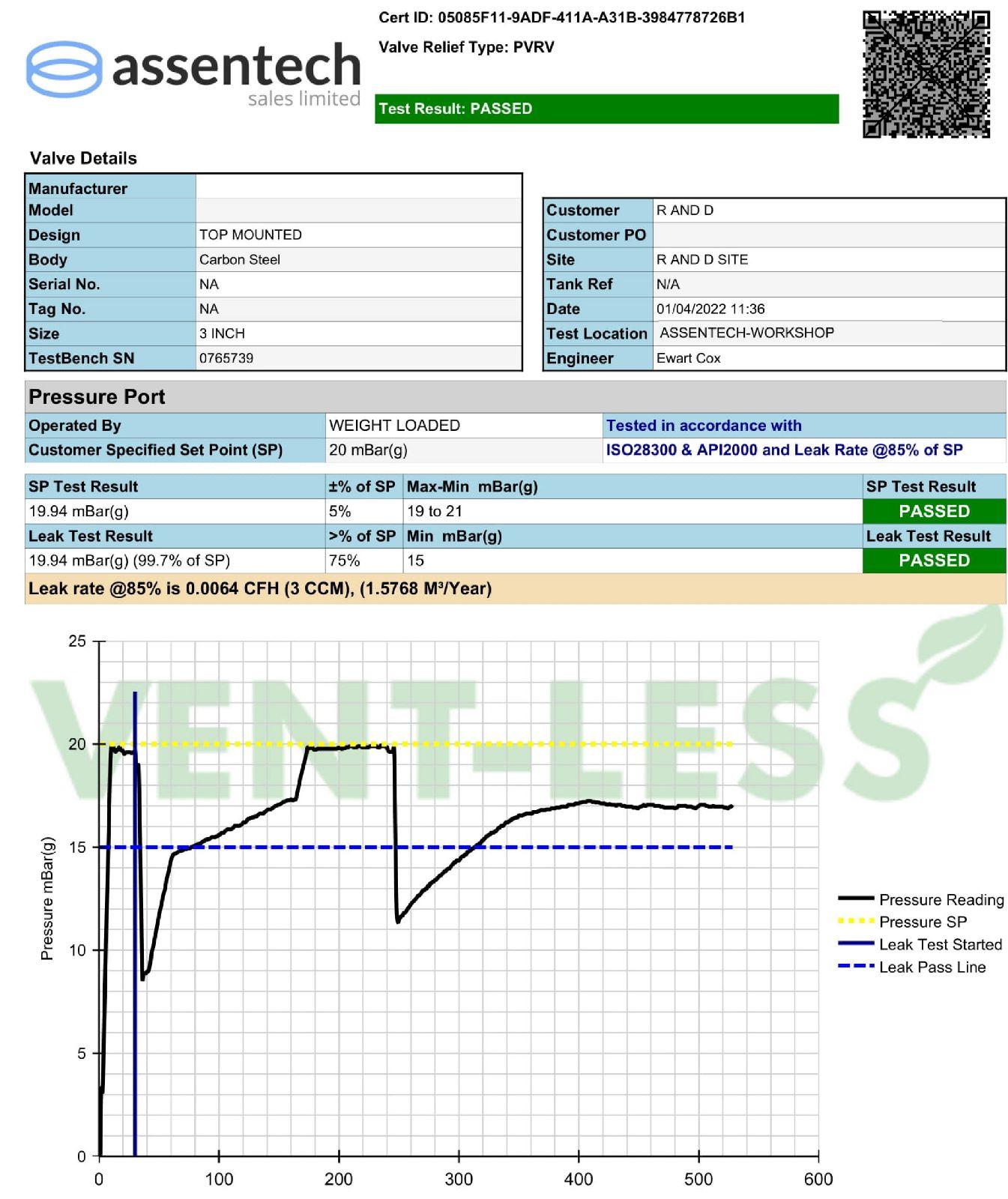

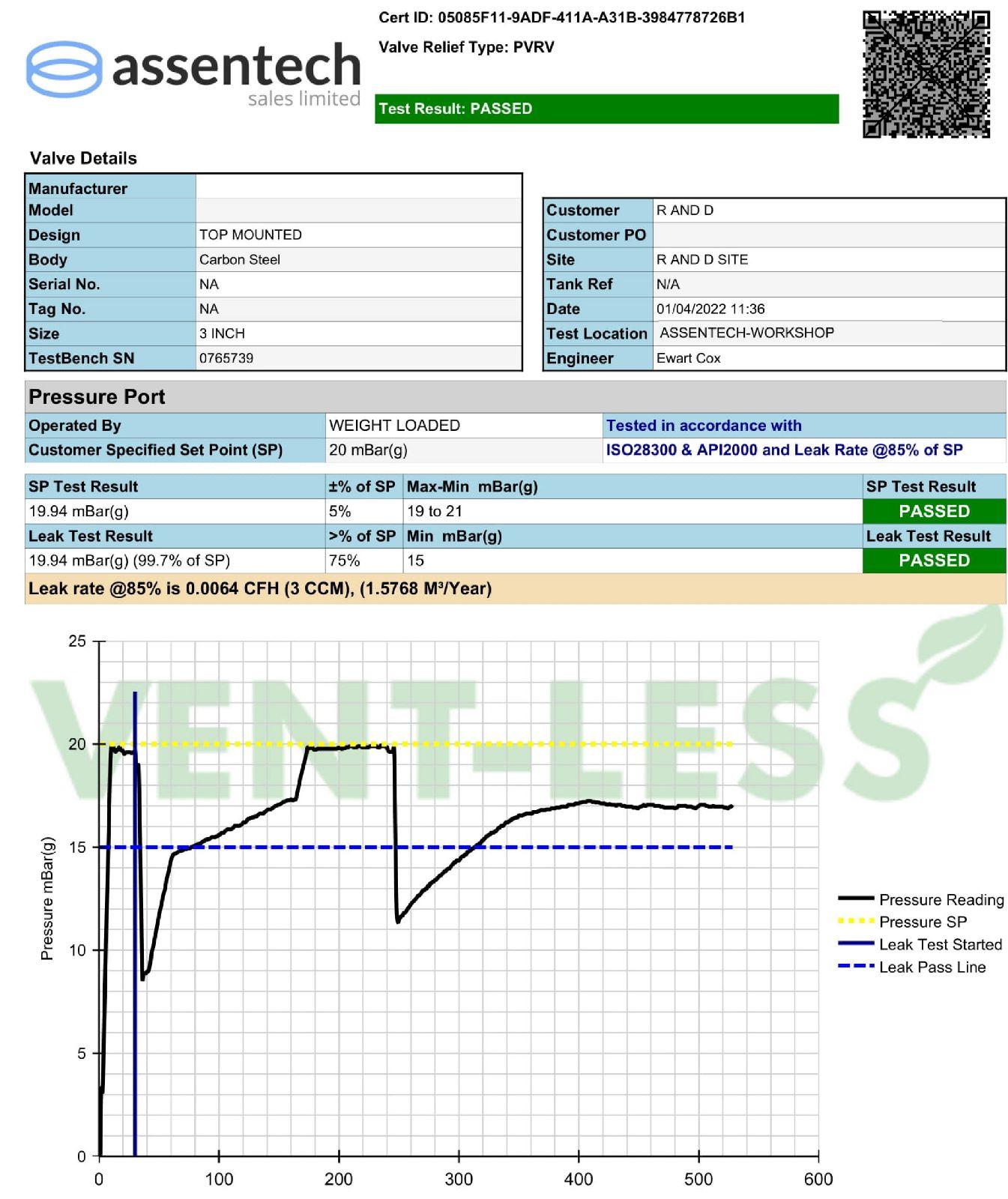

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Bottom Loading Arms

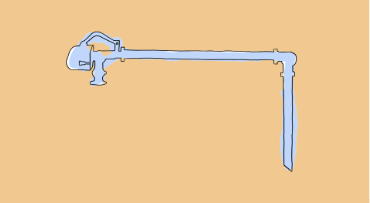

Top Loading Arms

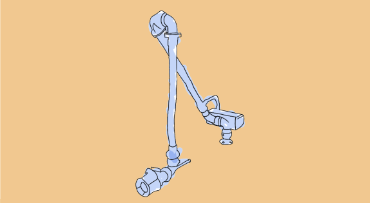

Swivels

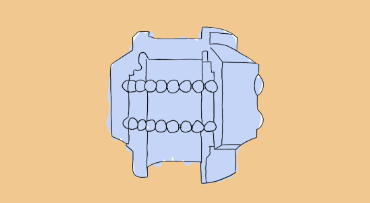

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Couplers and Adaptors

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact