The use of top-loading railcars and trucks remains an efficient and economical solution in a myriad of scenarios. A crucial component of this process is an optimally configured loading system.

A competent loading system should have ample horizontal range, enabling it to access the most remote compartment without necessitating vehicle repositioning. Furthermore, it needs sufficient vertical flexibility and adequate drop-pipe lengths to cater to vehicles of varying heights.

With thoughtful design, a top-loading system can fulfil these requirements whilst also offering protection. Moreover, top-loading arms are versatile instruments that can be utilised for a plethora of applications, such as tight-fill, vapour recovery, and marine operations. They can be specifically adapted for these tasks through the incorporation of specially engineered components, like vapour plates, tapered hatch plugs, and inflatable hatch seals.

In addition, our top-loading arm designs can be supplied with a broad range of valves, fittings, and instrumentation equipment to accommodate specific needs.

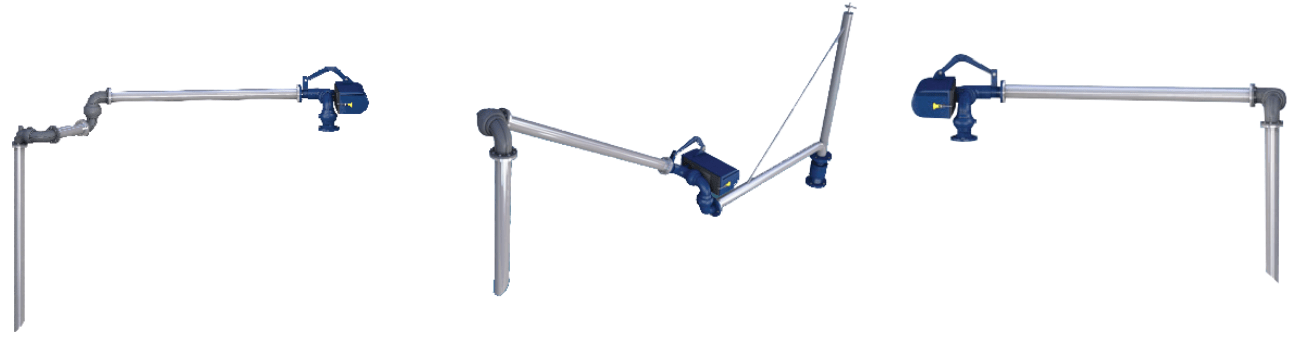

Types of Top Loading Arms we Supply

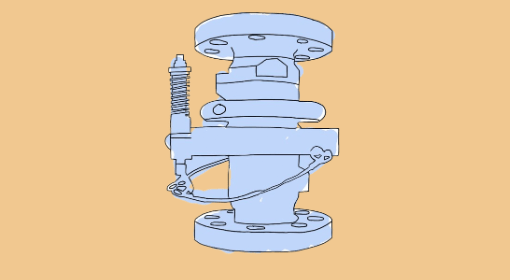

- Fixed Reach Style Top Loading Arm: This straightforward arm, designed for top-loading applications with a fixed vehicle range, integrates three swivel axes for versatile movement, accommodates internal or external valve placement to facilitate loading and reduce dripping of viscous products, and offers customisation options for tight filling or closed loading with additional swivel axes, drop hose, and necessary outboard coupling, union, or fitting.

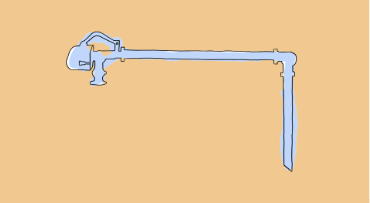

- Scissor Style Top Loading Arm: Designed primarily for loading and unloading tank trucks within a reach under 120″, this arm, optimal for top-loading installations requiring a flexible range, features a 360-degree horizontally rotating auxiliary arm for ample spotting allowance.

- Unsupported Boom Style Top Loading Arm: Boom style loading arms, offering extensive reach, unmatched flexibility, and simple operation, are ideal for applications requiring variable reach, especially with larger sizes and heavier outboard elements, and can include a support section for enhanced reach and weight handling, while also offering a practical, compact storage solution by folding back against the loading platform.

- Supported Boom Style Top Loading Arm: Boom type loading arms, ideal for tasks requiring variable reach and known for extended reach, unmatched flexibility, and straightforward operation, are particularly suitable for handling large sizes and hefty external elements, can be supplemented with a support segment to enhance reach and weight handling, and feature collapsible design against the loading platform for efficient, space-saving storage.

- Slide Sleeve Arm A-32-F: The slide sleeve model loading arm, perfect for top loading petroleum products in smaller plants, features a telescopic sliding sleeve for effortless drop tube positioning, offers a budget-friendly solution, but is limited to flow rates of up to 15 ft/sec to avoid overextending the inner tube.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

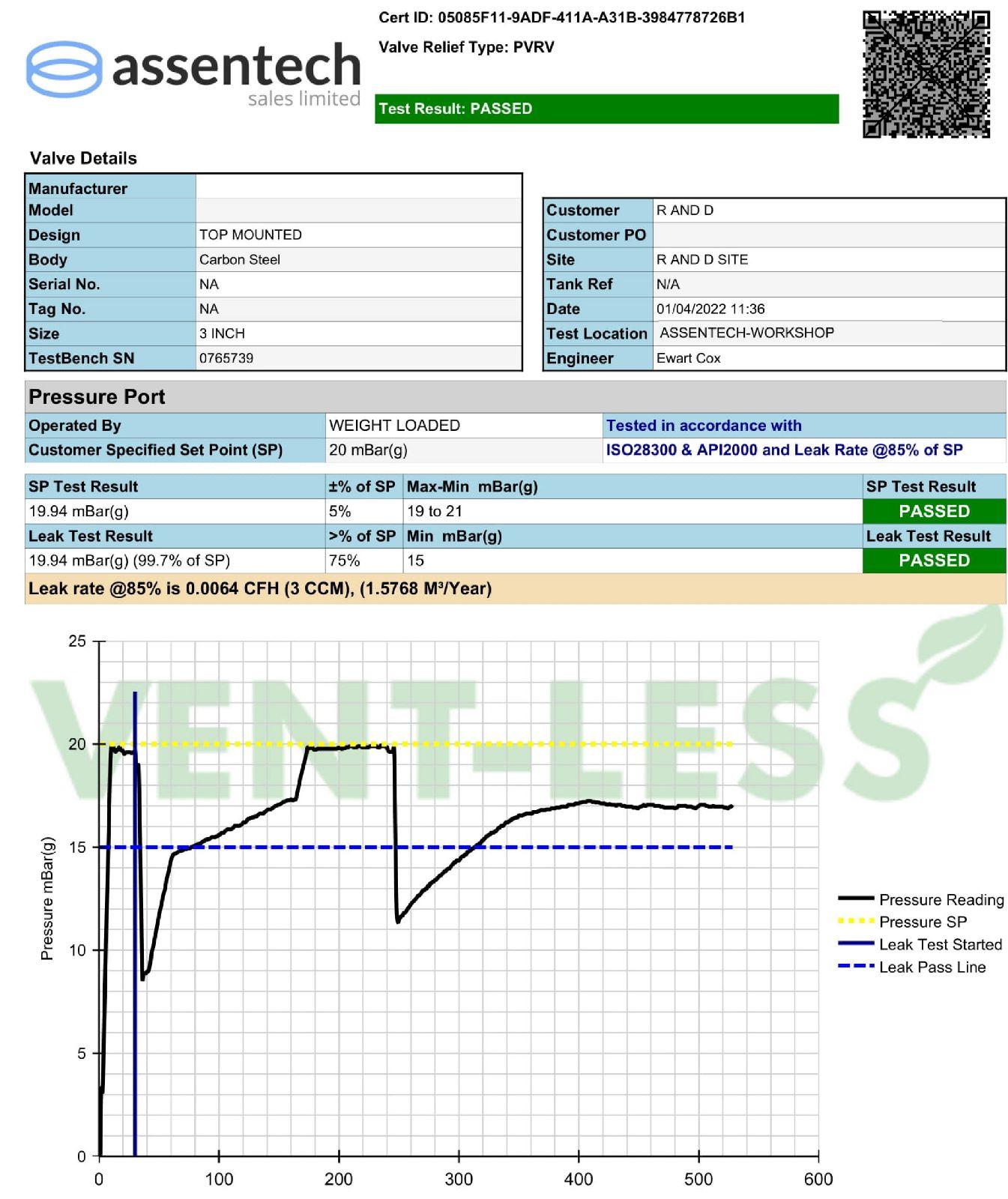

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

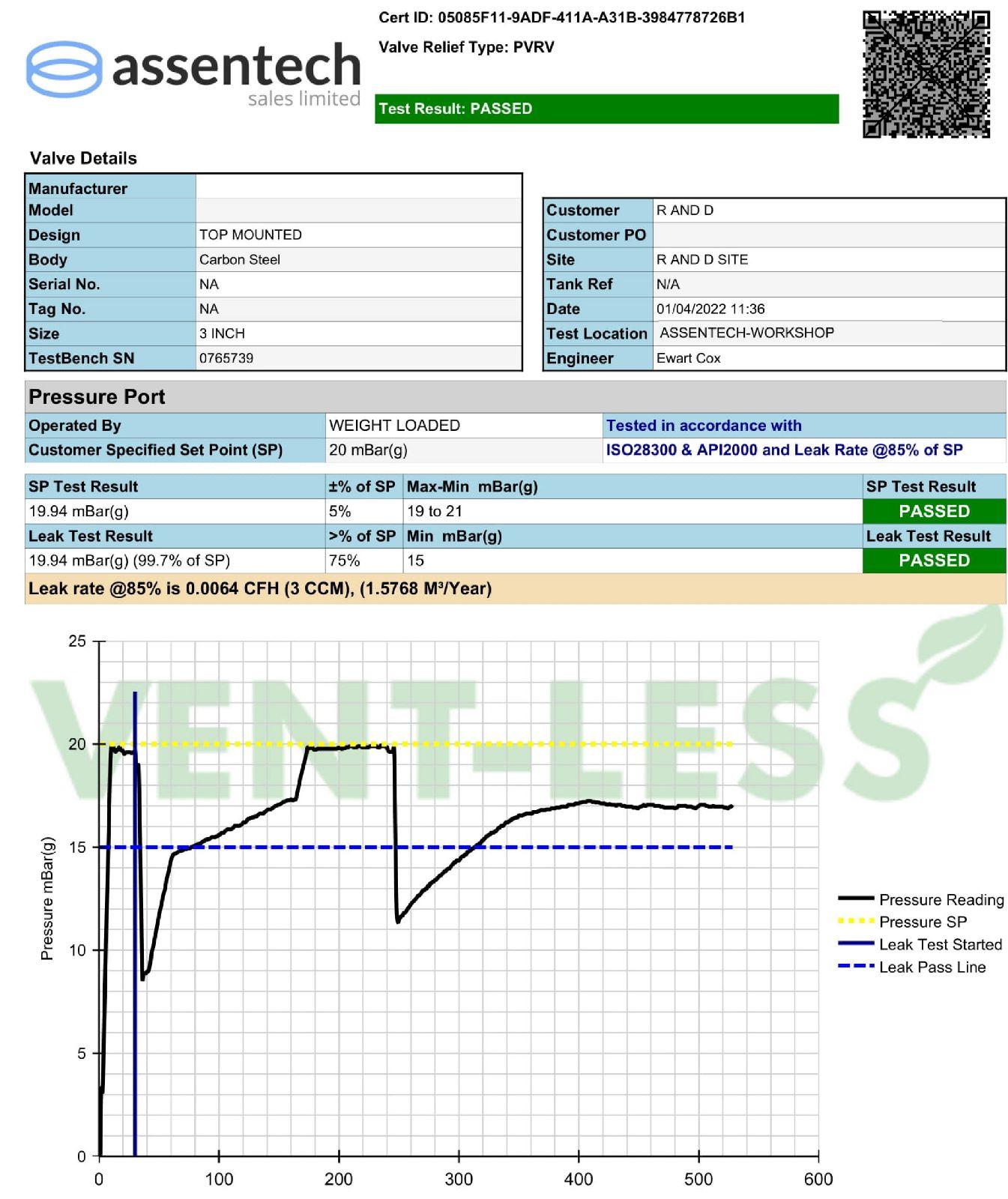

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Top Loading Arms

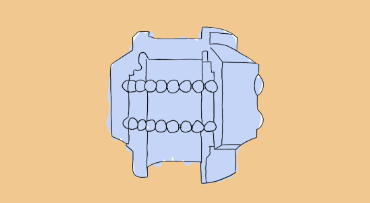

Swivels

Couplers and Adaptors

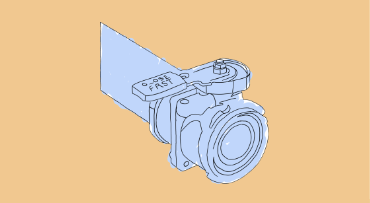

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact