Internal Floating Roofs IFR’s- Pontoon, Full Contact and Suspended Types

What is Internal Floating Roof-IFR?

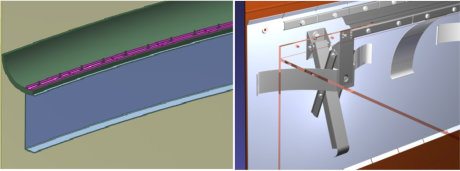

An internal floating roof, or IFR, comprises a steel or aluminium deck, which floats on, or just above the surface of the product within a vertical cylindrical storage tank. This deck has a seal around the outer edge which is tight enough to form a barrier but flexible enough to allow the deck to rise and fall with product level within the tank.

An internal floating roof, or IFR, comprises a steel or aluminium deck, which floats on, or just above the surface of the product within a vertical cylindrical storage tank. This deck has a seal around the outer edge which is tight enough to form a barrier but flexible enough to allow the deck to rise and fall with product level within the tank.

Why?

Because a correctly functioning IFR will prevent vapours from leaving the surface of the product and occupying the vapour space with a storage vessel – with adequate sealing, these vapours will remain below the deck which has a number of key benefits. Firstly, you protect the product from contamination with air and the moisture it contains – this is important with aviation fuels and in marine environments where ingress of air could also mean ingress of salt and moisture. Secondly, when the vapour space is occupied by air rather than a volatile vapour, it makes for a safer installation. Lastly, when a tank fitted with an IFR breathes or fills/empties, it will vent air rather than the valuable/dangerous/odorous/volatile/noxious vapour (product) which sits below the IFR.

In smaller tanks, a nitrogen blanket is often used as an alternative to an IFR. As the tank size increases, blanketing can become expensive unless nitrogen is freely available, making an IFR a cost effective long term solution.

Where?

Usually on large tanks (upwards of 15m diameter), IFRs are used by Fuel Terminals, Airports, Refineries, Fine Chemical Manufacturers, Sewage Works and anywhere where valuable, volatile, safety critical or finely refined product is stored.

IFR technology dates back to the 1950s and has evolved in line with the demands of customers and to keep abreast of legislation. Tank inspections are now routinely performed in 10 – 20 years intervals. Therefore, it is important that the IFR performs effectively throughout this period, without the need for intervention and maintenance. Pressure on profit margins can drive cost-cutting on capital equipment purchases and concurrent pressure to prevent production outages, so inspection schedules are likely to be pushed out even further. It is, therefore, important that any IFR technology meets those demands and performs robustly at an optimum level for longer periods of time than ever before.

Assentech has an enviable reputation for delivering quality at a competitive price. We have now completed many projects on time and on budget with commendations and testimonials from major UK infrastructure companies. Every IFR or Geodesic dome we fit has been engineered to suit the specific tank application. Drawings will be produced with specific details of the deck or dome complete with customer details, tank layout including location of key items such as manways, dip funnels etc. Our customers can’t afford to take risks with this kind of equipment. A failed IFR or collapsed dome is unthinkable so we rightfully question why some customers buy cheap decks and domes that are proposed without any apparent up front engineering or documentation.

IFR’s are fitted for one reason, to stop vapours leaking to the atmosphere. Tank inspection periods run from between 10 years and up to 20 years in some industries so why do customers buy cheap wiper seals that last only 3-5 years. Our stainless steel shoe seals last for at least 25 years. We feel that our fitted IFR’s give the best life cycle cost through sound engineering solutions.

The IFR’s we work with are designed and manufactured by Matrix Applied Technologies. Matrix Applied Technologies have long been the global leader in the design and manufacture of IFR’s, with 25 years practical tank experience and installations in over 80 countries Worldwide.

We primarily offer two types of IFR from Matrix Applied Technologies, their Heavy Duty Aluminium Pontoon Type IFR and the Matrix Applied Technologies Full Contact Aluminium Honeycomb Panel IFR. Each has been designed to overcome the many design problems that exist in other well-known brand IFR’s – offering value for money through low cost of ownership and long term durability.

Internal Floating Roofs Types:

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.