Fluid transfer equipment plays a crucial role in a wide range of industries, ensuring the safe, efficient, and controlled movement of liquids from one location to another. These systems are integral to operations in sectors such as oil and gas, chemical processing, food and beverage, and more. They not only streamline the production process but also help in maintaining the integrity of the fluids being transferred, preventing contamination and spillage.

At Assentech, we offer a comprehensive range of fluid transfer equipment designed to meet the diverse needs of these industries. Our products are engineered to the highest standards, ensuring reliable performance, durability, and safety.

Quality & Integrity: The Assentech Promise

We only supply top-tier, high-quality equipment. Committed to fulfilling customers’ needs, we ensure all our equipment is of the highest quality and integrity.

Fluid Transfer Equipment Product Range

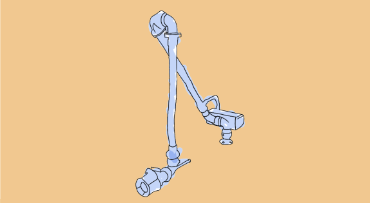

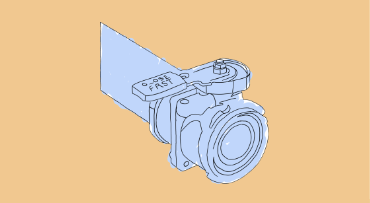

Top Loading Arms

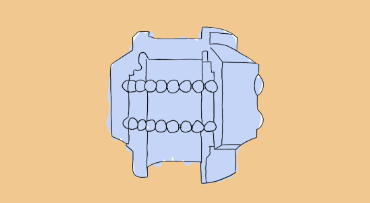

Swivels

Couplers and Adaptors

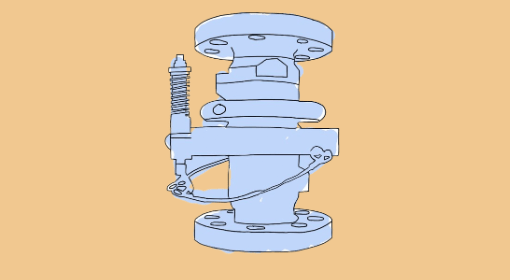

Rack monitors

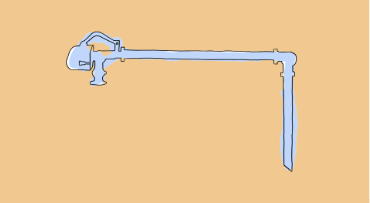

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Why Assentech?

| Factory technical support to ensure application suitability | Innovator of Vent-Less Technology, revolutionising tank breather vent testing to measure, monitor and reduce fugitive emissions | ||

| Accredited to ISO 9001, ISO 14001 and ISO 45001 by a UKAS certified body | Innovative solutions ranging from software to mechanical design | ||

| Fully traceable factory testing and calibration equipment | Manufacturers’ authorised service centre with access to factory technical support and maintenance updates. | ||

| Modular training programs establishes and tracks internal technical competence on task specific service activities | Representation on API2000 and ISO 28300 International Standards Committees | ||

| Tank storage, process safety and fluid transfer troubleshooting and maintenance support | Assentech’s comprehensive Service Reports and Test certification evidences best practice, compliance and duty of care | ||

| Experienced with COMAH sites, handling hazardous substances, RAMS generation and risk mitigation | Over 20 years of engineering expertise in the field of tank venting | ||

| Calibrated testing instrumentation is traceable to national standards | Consultative approach to cater to unique client requirements | ||

| Protected through a comprehensive Professional indemnity and Public Liability Insurance package | Assurance of customised, best-suited equipment for specific needs | ||

| Close collaboration with manufacturers to ensure optimal equipment selection | Capability to provide solutions in a variety of materials, including exotic and fibre reinforced plastics |

Why Assentech?

Advisor to the Environment Agency providing support and maintenance advice on best practice on tank storage applications

Innovator of Vent-Less Technology, revolutionising tank breather vent testing to measure, monitor and reduce fugitive emissions

Accredited to ISO 9001, ISO 14001 and ISO 45001 by a UKAS certified body

Innovative solutions ranging from software to mechanical design

Fully traceable factory testing and calibration equipment

Manufacturers’ authorised service centre with access to factory technical support and maintenance updates.

Modular training programs establishes and tracks internal technical competence on task specific service activities

Representation on API2000 and ISO 28300 International Standards Committees

Tank storage, process safety and fluid transfer troubleshooting and maintenance support

Assentech’s comprehensive Service Reports and Test certification evidences best practice, compliance and duty of care

Experienced with COMAH sites, handling hazardous substances, RAMS generation and risk mitigation

Over 20 years of engineering expertise in the field of tank venting

Calibrated testing instrumentation is traceable to national standards

Consultative approach to cater to unique client requirements

Protected through a comprehensive Professional indemnity and Public Liability Insurance package

Assurance of customised, best-suited equipment for specific needs

Close collaboration with manufacturers to ensure optimal equipment selection

Capability to provide solutions in a variety of materials, including exotic and fibre-reinforced plastics

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.