At Assentech Sales Limited, we proudly offer OPW Bottom Loading Arm Systems, an exemplary solution for loading and unloading petroleum products, chemicals, and liquefied gases. These systems provide significant advantages over conventional top-loading methods, including:

- Enhanced safety: With these systems, operators remain on the ground during loading/unloading operations, reducing risk

- Increased efficiency: Quick connections minimise overall loading/unloading time

- Reduced turbulence: Bottom loading causes less agitation in the tank, lowering the risk of static electricity generation

- Minimised vapour emissions: Bottom loading decreases vapour release, and the system can be adapted to recover displaced vapours

- Optimised loading: Tanks can be filled quicker, and multiple compartments can be loaded concurrently

- Cost-effective installation: Bottom-loading islands are simpler and more economical to construct than top-loading racks

Explore the benefits of OPW Bottom Loading Arm Systems with Assentech. We bridge the gap between you and the top-tier solutions in the industry.

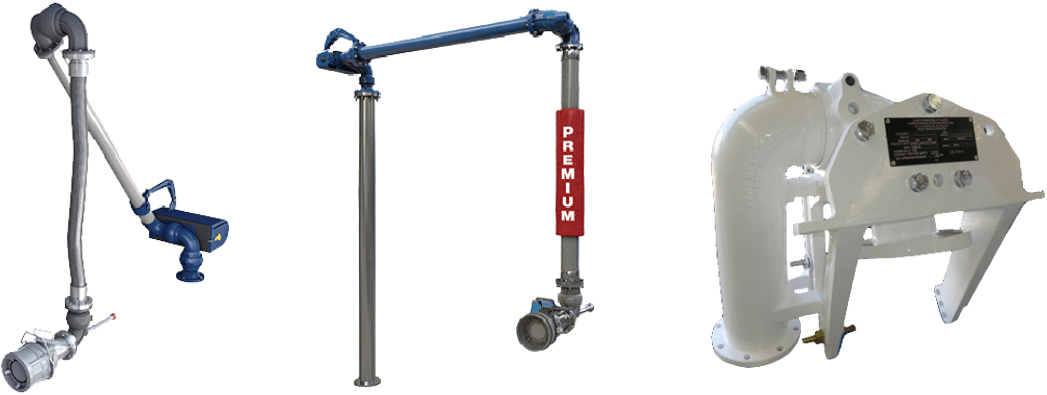

Types of Bottom Loading Arms we Supply

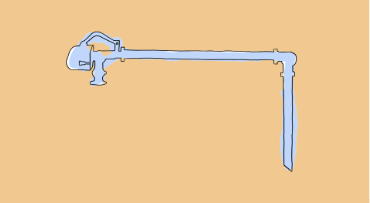

- Unsupported Boom Bottom Loader: A robust, user-friendly design, equipped with a minimum of five swivel rotation planes for flexible long-range operations and offering customisable features for diverse connections, thus easily adapting to changes in elevation, tilting, or different vehicle types, and facilitating compact storage, even in restricted areas.

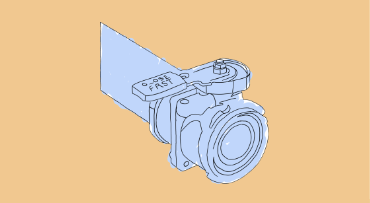

- A Frame Loader: Versatile, user-friendly, and known for its extensive reach, primarily used for bottom loading of tank trucks, but also capable of top-loading or unloading, and adept at handling liquefied petroleum gases, exemplifying its multifunctional value.

- “A” Frame Hose Loader AFH-32-F: Similar to traditional A-Frame Loaders, utilise flexible hose over rigid piping for the secondary/outboard arm, allowing compact storage and set up in close proximity, capable of loading from both sides of a bay, and apart from bottom-loading petroleum, they are also used for vapour recovery, underscoring their versatility.

- CWH Series Counterweighted Hose Loader: Offer easy installation and operation, featuring adjustable counterweights for efficient handling, reliable swivel joints for convenient maintenance, a flexible drop hose, and quality aluminium components, demonstrating their high functionality and superior quality.

- Short Range Hose Loader: Notable for their capability to simultaneously connect and fill up to three product lines, require minimal adjustment for alignment, boasting a proven track record in oil terminals worldwide for their affordability, low-maintenance, user-friendliness, and reliable, cost-efficient solutions.

- Long Range Hose Loader: Mirror the functionality of counterweighted hose loaders with easy alignment to tank truck adaptors and innovative design, the primary distinction being their use of a torsion spring instead of weights for user-friendly operation.

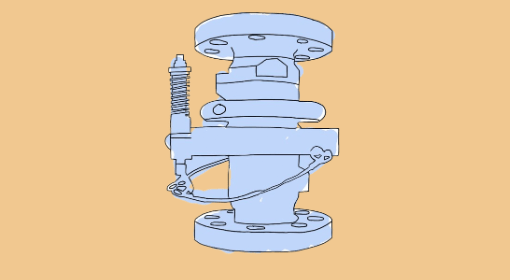

- LBM800 Liquip Balance Mechanism: Offers superior safety, longevity, and minimal maintenance, facilitates effortless bottom loading in petrochemical distribution terminals through its distinctive “Velvet Touch” design, and features 360-degree horizontal rotation and versatile vertical plane swivel, enabling smooth operation and convenient adaptability for servicing vehicles on either side of the loading bay and positioning the coupler at varying heights.

- Velvet Touch MK2 Balance Assembly: Designed for bottom-loading arms in petrochemical-distribution facilities, features a 360-degree horizontal-plane swivel for covering a standard API envelope’s width, a vertical-plane swivel for accommodating varying coupler-height requirements, and synergises with twin lift-O-mat struts, reducing the effort required for API coupler positioning, thereby enhancing user convenience and efficiency.

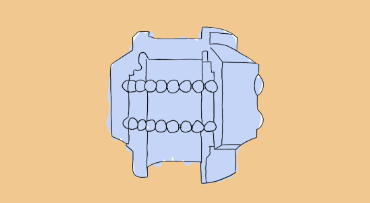

- Compact Torsion Swivel (CTS) Hose Loader: Perfect for tight clearances, feature a fully integrated internal torsion spring for a sleek profile that fits in compact spaces, making it an ideal replacement for current FMC TL Loaders or space-restricted applications, with a design focused on ease of adjustment and maintenance, offering a user-friendly experience.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

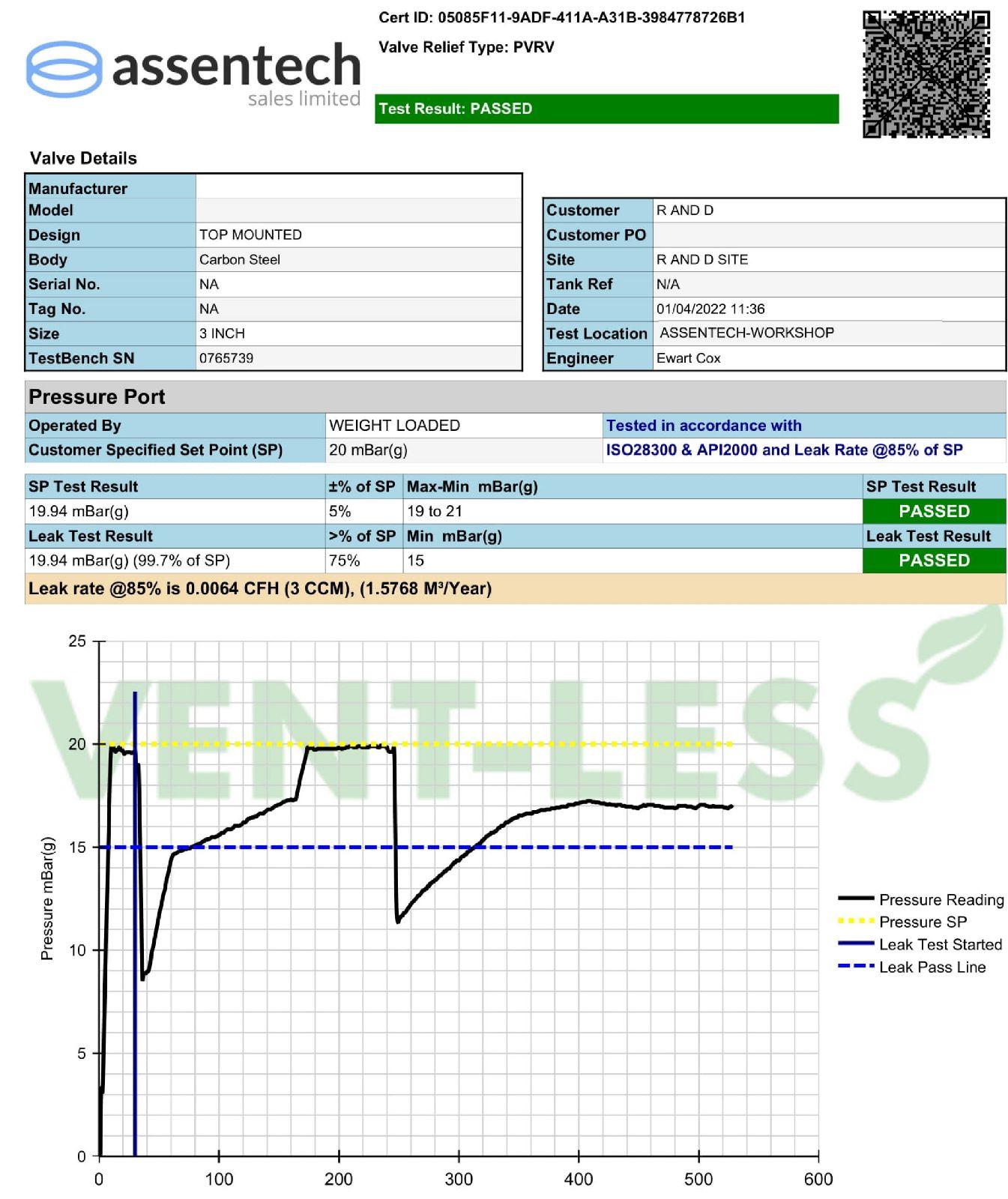

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

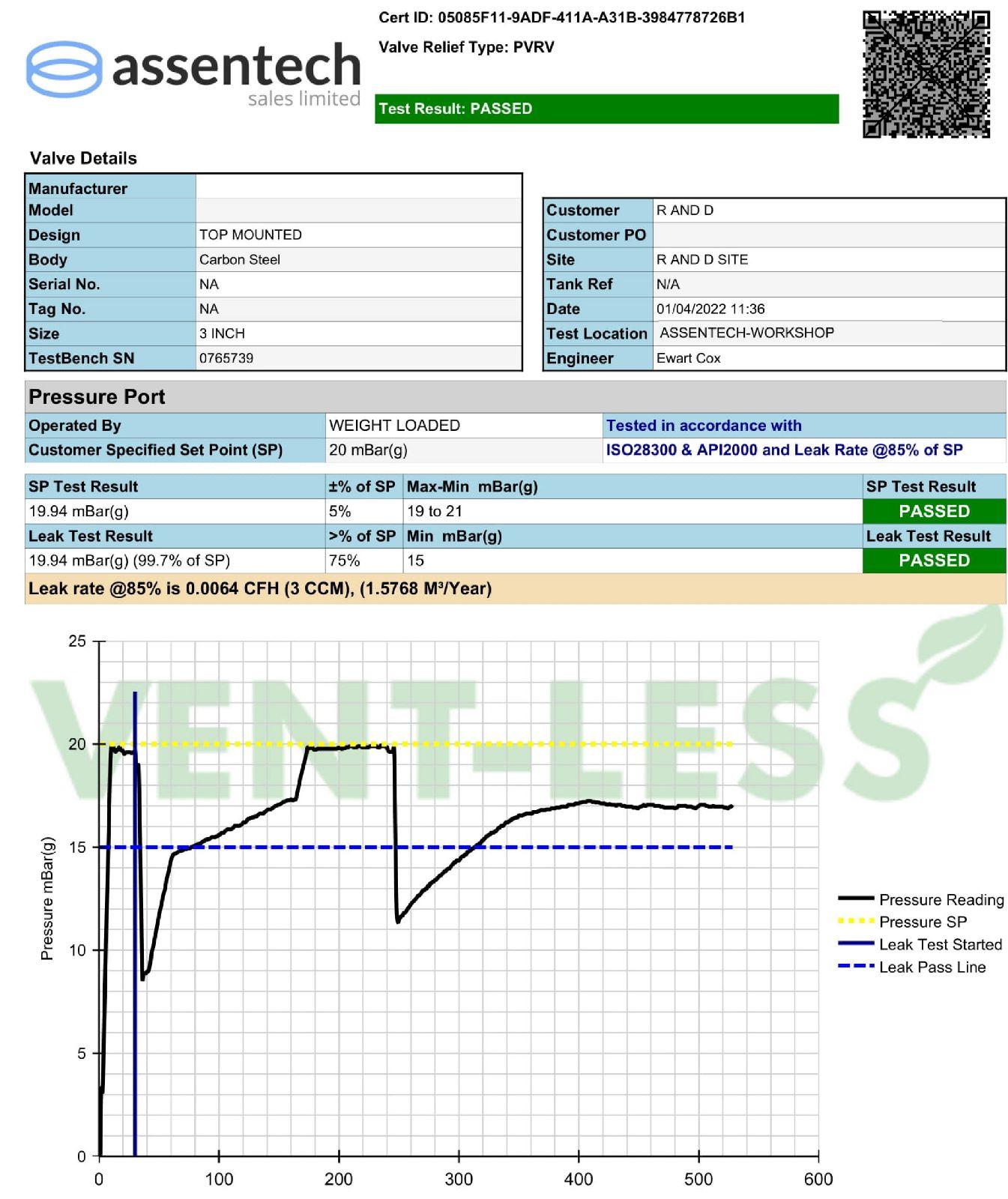

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Top Loading Arms

Swivels

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact