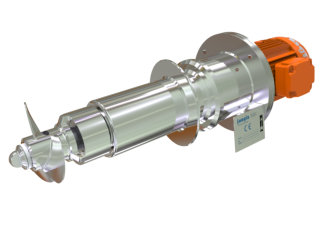

Bottom Entry Agitators/Mixers

Bottom entry mixers are available in three weights; light, medium and heavy. All are for applications of various liquid viscosities.

Light:

- Best for dairy products homogenous and vegetable oil or juice storage.

- Fluids which are easily mixed or kept homogeneous

- Small tank volumes

- Low viscous fluids

- Tanks with low pressure (max. 10 bar g)

- Temperatures from -20 °C to 150 °C

- Generated torque relatively low

Medium:

- Best for vegetable oil storage, dairy products and juice storage.

- Mixing applications where higher forces are required

- Larger tank volumes up to approx. 100 m3

- Viscosities range up to approx. 5000 cP

- Pressurized tanks (max. 16 bar g)

- Temperatures from -20 °C to 170 °C

Heavy:

- Blending (petro)chemical, food or pharmaceutical products for instance in reactors are examples of heavy-duty applications where bottom entry agitators and mixers are selected.

- Mixing applications where extremely high forces are required

- Very large tank volumes where a bottom bearing is not desirable

- Highly viscous fluids exceeding even 100.000 cP

- High-pressure tanks exceeding even 100 bar g

- Temperatures exceeding even 250 °C

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.