Vapour Recovery Unit Operation Energy Management

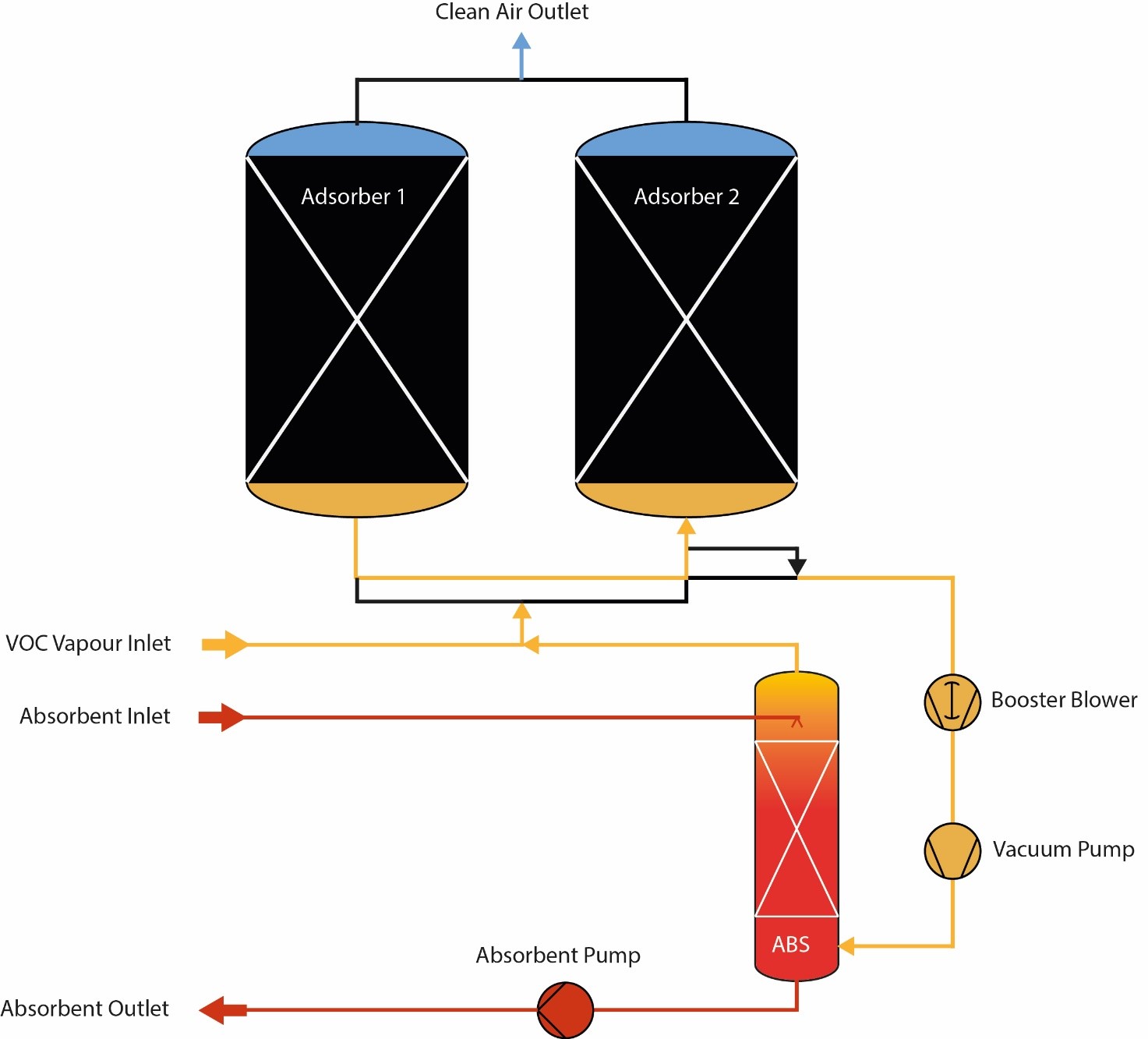

For oil distribution terminals, in which VOC vapour may be returned from loading of ships and/or includes VOC vapour balancing with storage tanks, the DTL VRUs includes a feature for a very high rate of energy saving, called adsorber to adsorber equalisation (ATAE). 20% of the energy usage in a pressure swing VRU, is spent by the vacuum system on evacuating the adsorber vessels from atmospheric pressure down to 50% vacuum. In the DTL VRUs, the adsorber vessel which has finalised the regeneration of the activated carbon and still is at 90% vacuum, is equalised back to a higher pressure from the other adsorber vessel, which is at atmospheric pressure and going into regeneration. The resulting pressure of the two vessels after the equalisation is 45% vacuum.

The evacuation of air or inert gas, from the second adsorber vessel going into regeneration, from atmospheric pressure down to 45% vacuum, comes for free, as the vacuum system does not spend energy on this part of the evacuation. The optimised vacuum systems and the ATAE energy-saving features, built-in as default to the DTL VRUs, reduces the energy consumption of the DTL with 20 – 50% per m3 VOC vapour processed, relative to conventional pressure swing VRUs.

Another energy-saving feature built-in default to the DTL VRUs is the emission control energy manager (ECEM). The ECEM measure the VOC emission in the vent from the VRU, and when the VOC emission reaches a pre-set value, adsorption switches from one adsorber to the other, and start the regeneration of the adsorber which is saturated with VOC. When loading in the terminal is below the design volumes, or loading of products mainly consist of gas oil or diesel, resulting in VOC concentration of the vapours below design figures, the adsorbers will last longer time before saturation, and the vacuum system will rest for a longer period.

As oil distribution terminals typical have peak loading hours and low loading hours throughout the day, the ECEM will show significant energy savings in the low loading hours. Combining the optimised vacuum systems, the ATAE and ECEM energy-saving features of a DTL VRU will obviously save a considerable amount of OPEX in an oil distribution terminal equipped with a VRU, over the year, compared to conventional VRU.

Morten Reimer Hansen

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.