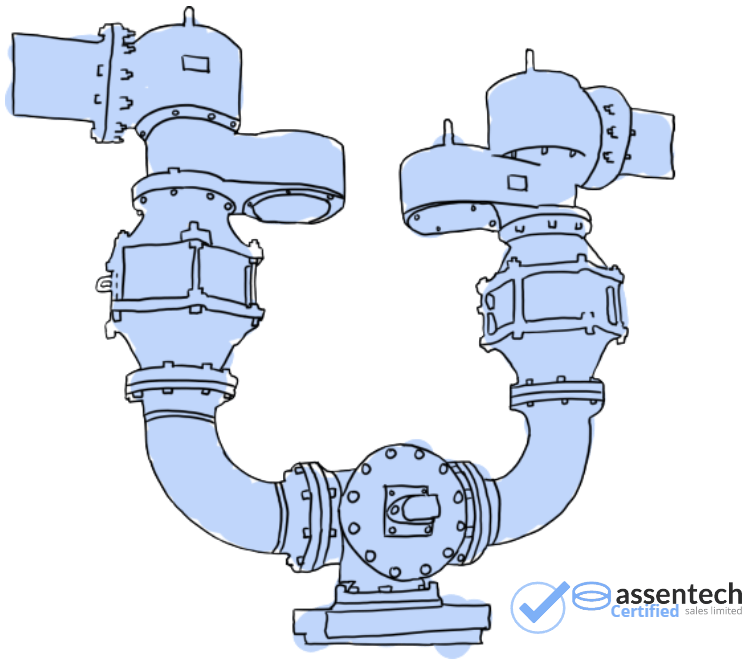

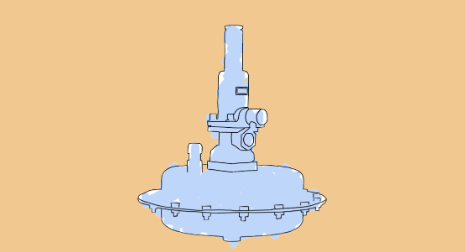

What is a Safety Diverter or Changeover Valve?

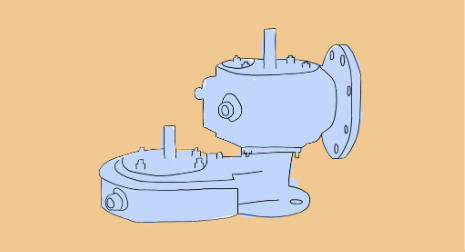

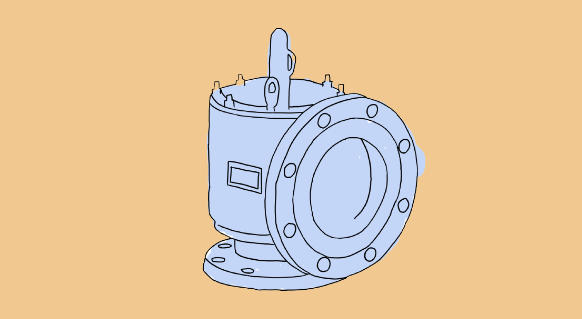

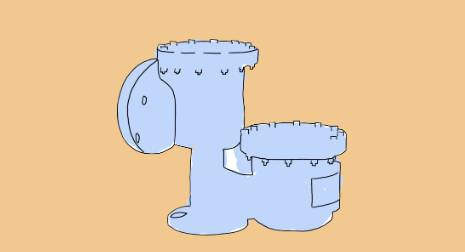

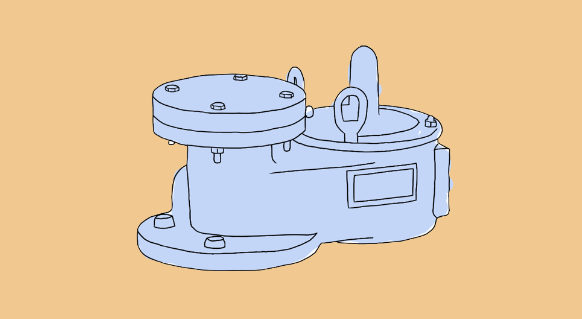

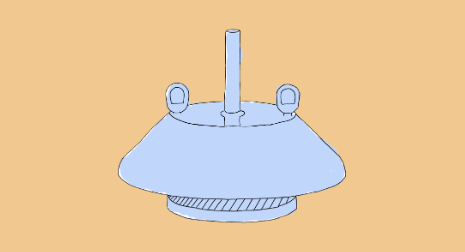

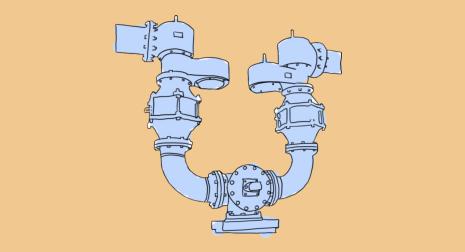

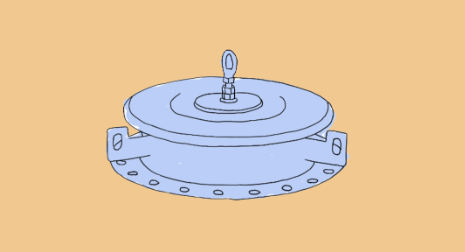

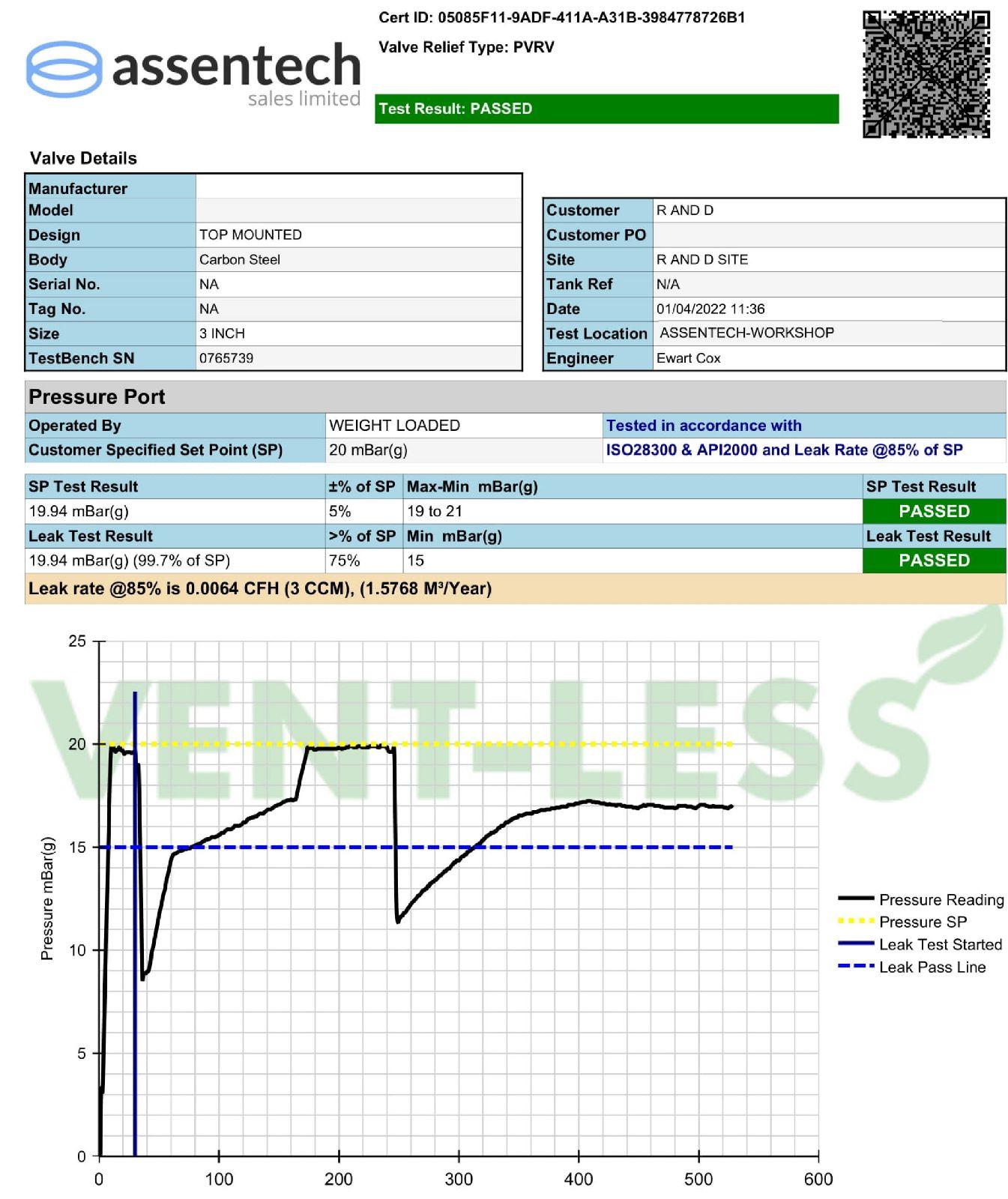

A Safety Diverter Valve (SDV), also known as a Changeover Valve, is a 3 way, multi port ball valve designed to ensure continuous operation of critical assets such as storage tanks, chemical processing units, and bio digesters. It provides a safe, quick, and convenient method of switching between two breather valves or pressure/vacuum relief valves without interrupting the process.

This design allows facilities to isolate one valve for inspection, calibration, or replacement, while the other continues to protect the system. The ability to carry out maintenance without downtime is vital in industries where tank shutdowns are rare, costly, and often operationally impossible.

Why are they needed?

Tanks are typically shut down only once in 10 years or longer. In contrast, breather valves and pressure/vacuum vents are constantly in service, cycling thousands of times as product moves, pumps run, and temperatures fluctuate. Over time, even the highest quality valves can begin to leak due to wear, fouling, or seal degradation.

Without a changeover system, servicing these valves would require process interruption or reliance on untested equipment, exposing operators to risk and increasing costs. Safety Diverter Valves eliminate this issue by providing a controlled, engineered solution for valve changeover.

How do they work?

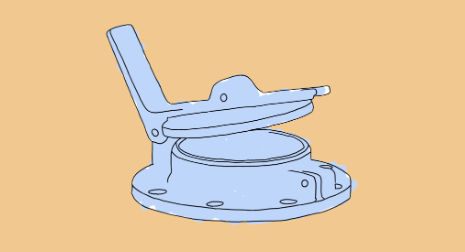

The valve body is engineered with three ports and a precision machined ball. By operating a simple lever, the flow path is instantly redirected from the active breather valve to a standby unit. This ensures:

- No loss of tank protection during maintenance

- Immediate isolation of the out of service valve

- Safe handling of hazardous media such as hydrocarbons, solvents, or H₂S gas

- Rapid return to full capacity once maintenance is complete

Key Benefits

- Unbroken Production – Breather valve maintenance no longer depends on rare and costly shutdown windows. Processes remain fully operational while valves are isolated and serviced.

- Improved Safety – Engineers can isolate a valve without exposure to hazardous vapours. The standby valve ensures the tank remains protected at all times, reducing the risk of overpressure or vacuum collapse.

- Lower Operating Costs – Ultra tight sealing and optimised 10% overpressure settings reduce nitrogen blanketing losses, cut fugitive emissions, and minimise product evaporation. Savings of up to 88% per cycle are possible.

- Regulatory Compliance – Enables facilities to meet Environmental Agency, EPA, and ISO requirements for emissions control by reducing unplanned leaks and ensuring valves remain within certification tolerances.

- Sustainability Gains – Reduced nitrogen use and fewer product losses directly support environmental and sustainability targets while lowering the facility’s carbon footprint.

Fast Return on Investment

For larger valves (up to 12”), facilities typically save around £900 per valve each year on nitrogen alone. When extended valve life, reduced maintenance labour, and freedom from unplanned downtime are factored in, the investment in a changeover valve can often be recovered within the first year of operation.

Applications

- Tank farms handling crude oil, refined fuels, and chemicals

- Biogas plants with digesters producing methane and CO₂ mixtures

- Pharmaceutical and food industries where contamination and emissions must be strictly controlled

- Chemical plants managing aggressive or toxic vapours

Smarter Maintenance

A changeover valve is not just an accessory — it is an enabling technology that transforms breather valve maintenance into a proactive, strategic, and measurable investment. Facilities gain reliability, safety, and compliance while reducing operating expenditure and strengthening their environmental performance.

Sizing Programme for Breather Valves available on request

| Sizing Programme for Breather Valves available on request |  |

- 3-way, multi-port valves are available in L Port or T Port configurations for versatile operation.

- Low-pressure drop-off ensures unrestricted flow, while a blow-out-proof stem maximises safety.

- Live-loaded stem packing ensures positive sealing and the high sphericity of the ball ensures positive shut-off with low torque.

- Equipped with a standard handle lever and optional gear operator, along with a visual indicator for valve activity.

- Standard lock-out mechanism for security, and suitable for mounting two pressure vacuum relief valves.

- Optional threaded ports with manual valves for pressure testing and field calibration.

- 3-way, multi-port valves are available in L Port or T Port configurations for versatile operation.

- Low-pressure drop-off ensures unrestricted flow, while a blow-out-proof stem maximises safety.

- Live-loaded stem packing ensures positive sealing and the high sphericity of the ball ensures positive shut-off with low torque.

- Equipped with a standard handle lever and optional gear operator, along with a visual indicator for valve activity.

- Standard lock-out mechanism for security, and suitable for mounting two pressure vacuum relief valves.

- Optional threaded ports with manual valves for pressure testing and field calibration.

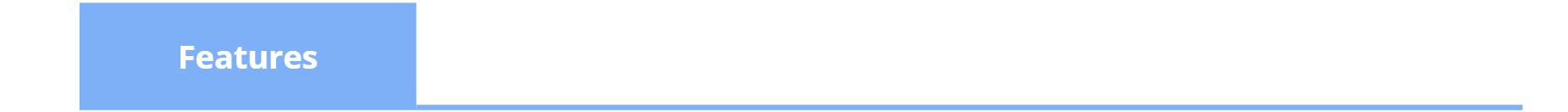

One of the defining features of our Pressure Relief Valves is their leak-tightness. The importance of a leak-tight valve cannot be overstated in industries where even the smallest leak can lead to significant product loss, potential harm to personnel, and environmental pollution. All our valves are supplied with individual leakage and calibration certificates, as per ISO 28300 & API 2000 standards. We believe it’s important to note that while some manufacturers only supply calibration certificates, neglecting leakage tests, we ensure compliance with the aforementioned standards. Each valve we supply is tested meticulously, a process typically requiring at least an hour at the factory. This critical quality assurance step is included in our base price, reflecting our commitment to safety and quality.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation/Certification List

Individual Documentation/Certification can be requested from the following list as applicable

- API2000 Production Functionality Test Report to section 5.4 including Set pressure and leak rate with traceability to EN 10204.3.1. Not available for spare parts

- Volume Leak Rate Test report at customers specified operating pressure between 65% < 90% of set point. Suitable for LDAR reporting.

- Pre-Commissioning Safety and Functionality Report

- Emissions Quantification LDAR Survey and report on installed valves

- Facilitating Inspection and/or witness test

- Certificate of Conformance

- GA Drawing & Parts List for Information

- Certified Drawings

- Material Test Report acc to EN 10204.3.1

- Certificate of Origin (if required - attested by Local Chamber of Commerce).

- Inspection and Test Plan (ITP).

- Manufacturer Record Book

- Works Inspection Certificate 3.1

- Material Inspection Certificate 3.1

- Casing Pressure Test for Integrity

- Installation & Operation Manual

- ATEX certificate of conformity

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.

Venting Equipment Product Range

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Assentech Academy - Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact