Assentech is the innovator behind the vent-less breather valve test bench, delivering automatic testing to evidence API2000 compliance, provide accurate leak rate data, and support informed decisions. Leading supplier of a diverse range of environmental solutions, technical consultancy and product supply for the tank storage, process safety and fluid transfer industries.

As an active member of 2 international standards committees and a member of ADBA, Assentech is a recognised authority in best practice—offering trusted technical expertise to drive compliance, reduce emissions, enhance safety, and boost profitability.

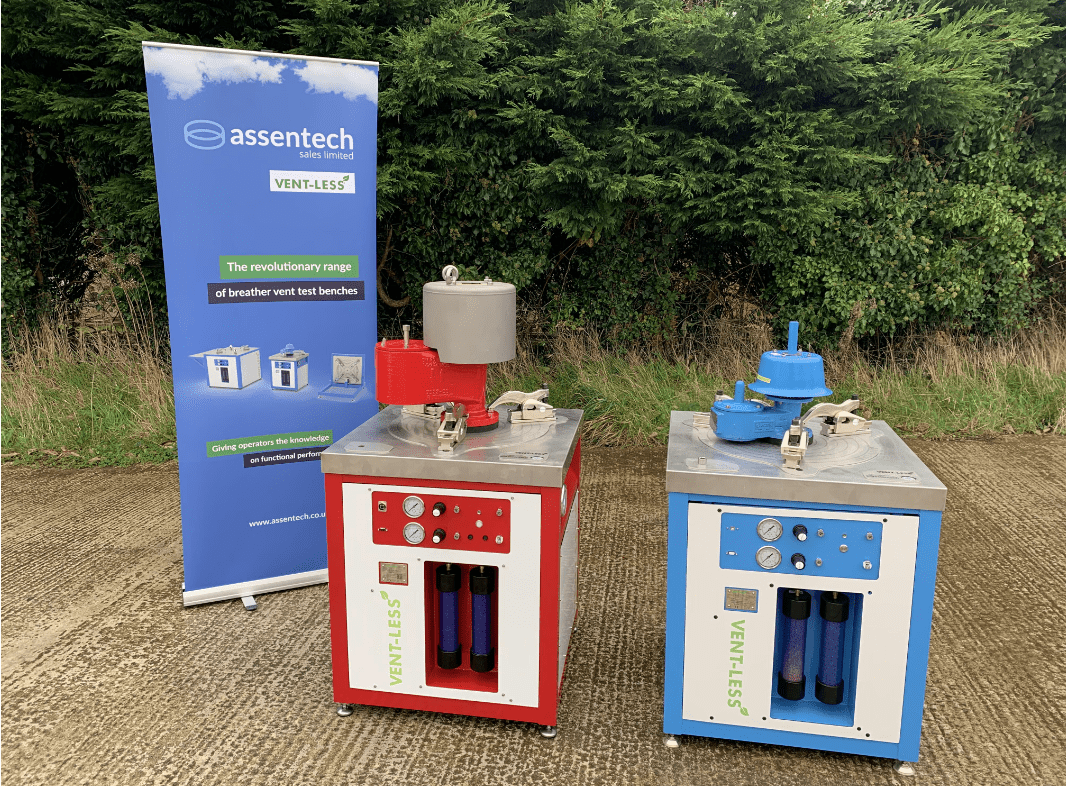

VENT-LESS TEST BENCH RANGE

Test the integrity and performance of breather valves under real-world tank venting scenarios.

Key Features:

- Mobile, fixed and high-volume models

- Fully compliant with API 2000 and ISO 28300; supporting compliance with Environment Agency Appropriate Measures guidance.

- Automatic test including both pressure and vacuum ports.

- Verifies set point and settings.

- Enables proactive valve maintenance and fault detection.

- Facilitates Scope 4 (avoided emissions) reporting.

LEAK RATE CERTIFICATION

Purpose: Provide verifiable data on breather valve emissions performance.

Key Features:

- Each valve we supply includes an API2000 certified test report which includes leak rate.

- Provides evidence of individual leak rate measurement and improvement data.

- Documents compliance for audits, regulators and LDAR compliance.

- Provides information for informed decisions and historical results for individual assets.

- Helps reduce emissions by targeting underperforming valves

VAPOUR RECOVERY UNITS (VRU)

Capture VOC vapours from storage tanks and digesters.

Key Features:

- Vacuum or steam-regenerated VRU systems.

- Custom configurations with or without absorption modules.

- Suitable for methane-rich vapour streams (e.g. cyclohexane, heptane, octane).

- Benefits: Compliant with UK BATC and Industrial Emissions Directive.

- Recovers energy and reduces flaring.

- Prevents uncontrolled vapour loss and odour issues.

LDAR (LEAK DETECTION AND REPAIR)

Identify fugitive emissions and reduce uncontrolled methane loss from critical components.

Key Features:

- OGI (Optical Gas Imaging) surveillance by trained and competent operatives.

- Use of Vent-Less test bench for detailed leak rate quantification.

- Covers breather valves, Emergency Relief Valves (ERVs), and Blanket Gas Regulators Benefits.

- Pinpoints sources of emissions for prioritised maintenance.

- Provides robust evidence for environmental reporting.

- Supports compliance with Appropriate Measures, BAT, and ESG frameworks.

INTERNAL FLOATING ROOFS (IFRS)

Reduce evaporation losses and control emissions in storage tanks.

Key Features:

- Suitable for a wide range of tank diameters and product types.

- Available in aluminium and stainless steel, or composite materials.

- Floating or fixed design.

- Minimises vapour space to reduce breathing losses.

- Enhances safety by lowering flammable atmosphere risk.

- Supports emissions reduction targets and sustainability goals

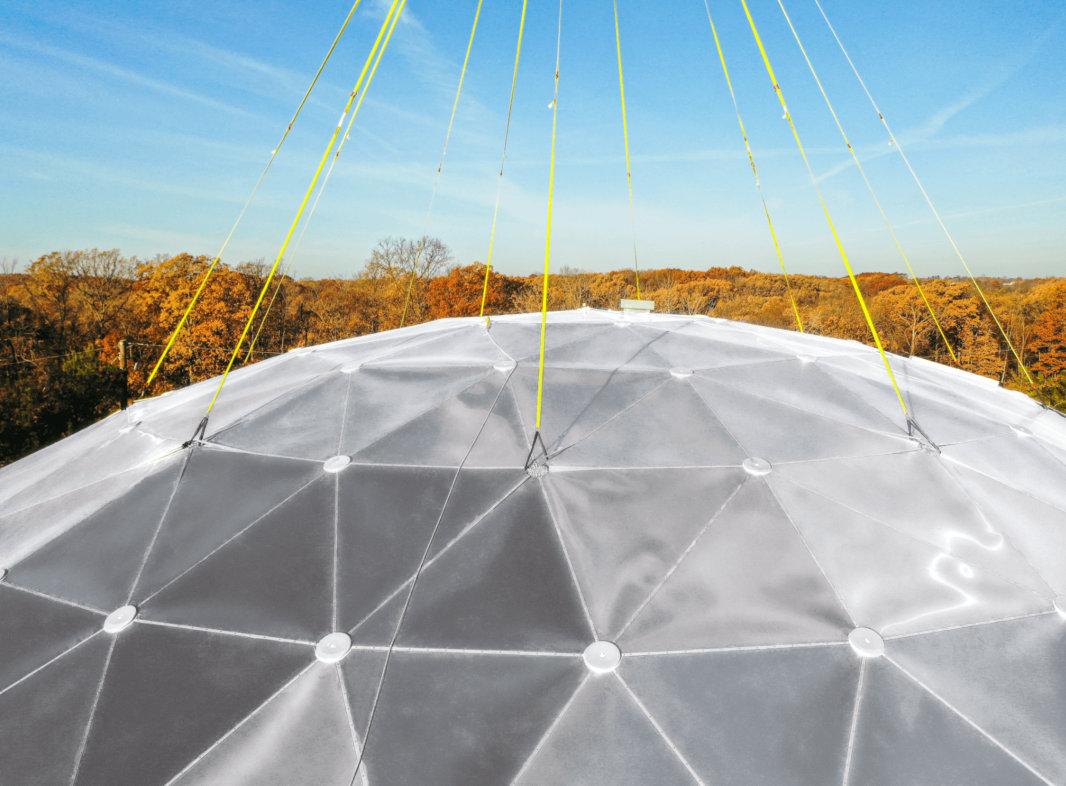

GEODESIC DOMES

Provide a durable, lightweight, and emission-tight cover for aboveground storage tanks.

Key Features:

- Corrosion-resistant aluminium or stainless-steel construction.

- Custom-engineered to fit existing or new tanks with factory design expertise.

- Suitable for use with IFRs to create a closed emission system.

- Reduces rainwater ingress and vapour emissions.

- Low maintenance, long service life.

- Supports long-term compliance with environmental regulations.

🛠 A Smarter Approach to Managing Aging Assets

Effective management of aging plant—particularly breather valves—starts with clear visibility of asset data.

📆 Service Frequencies Aligned to Risk

While annual inspections and three-year servicing are often used as a baseline, the ideal schedule depends on the application and your site-specific risks: media characteristics (viscosity, corrosivity, flammability, toxicity), valve age, historical valve performance, service/maintenance history, location of install, ie, indoors, valve build quality and compliance records.

🔍 Data-Driven Decisions Using Vent-Less Testing

Service frequency can also be refined by analysing Vent-Less test results taken at the pre-service stage. This test determines whether the valve is leaking or out of calibration. At this point, the valve should demonstrate accurate settings, safe functionality, and full compliance with API2000. These insights allow for evidence-based adjustments to service intervals, rather than relying solely on fixed timelines as in order to maintain protection and fulfil their role, they should maintain optimum performance with no dips.

🔁 Swap-In/Swap-Out = Maximum Uptime

For hard-to-reach breather valves and those applications that would be costly and pose a high risk with downtime, a swap-in/swap-out programme enables a spare valve to be with the same settings and spec to be ordinarily stored on site and used as a back up unit.

📦 Note: A critical factor for this model is ensuring store inventory is clearly detailed for asset traceability on management of aging assets records.

📁 Audit-Ready and Easy to Manage

Robust service schedules aid in regulatory compliance, simplify audits, and make it easier to manage maintenance proactively—supporting better outcomes for operators and the environment.

Explore more below.

Vent-Less

ESG – Emissions Calculator

LDAR Leak Detection and Repair

Method 21: Leak Detection and Repair (LDAR)

Innovative Domes for Biosolids Tanks

Sustainability & Environment

Vent-Less

LDAR Leak Detection and Repair

ESG – Emissions Calculator

Innovative Domes for Biosolids Tanks

Method 21: Leak Detection and Repair (LDAR)

Sustainability & Environment

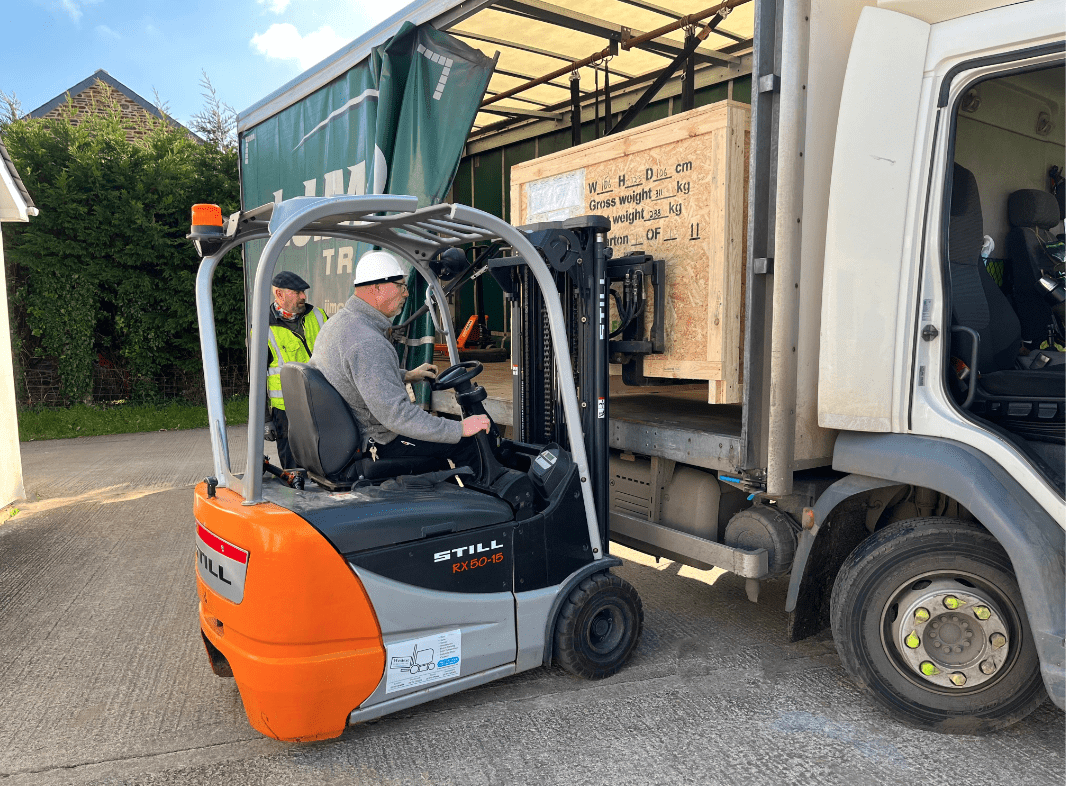

Continuing our commitment to emission control, Assentech also offers breakaway and dry disconnect couplers—engineered to prevent fluid leaks during tanker drive-offs and enable quick, safe disconnection without spillage.

HELPING OPERATORS ADHERE TO REGULATIONS, PLAN TEST SCHEDULES, REDUCE EMISSIONS, AND STRENGTHEN AUDIT READINESS—EMPOWERING BETTER DECISIONS, SUSTAINABILITY REPORTING, AND REGULATORY CONFIDENCE.