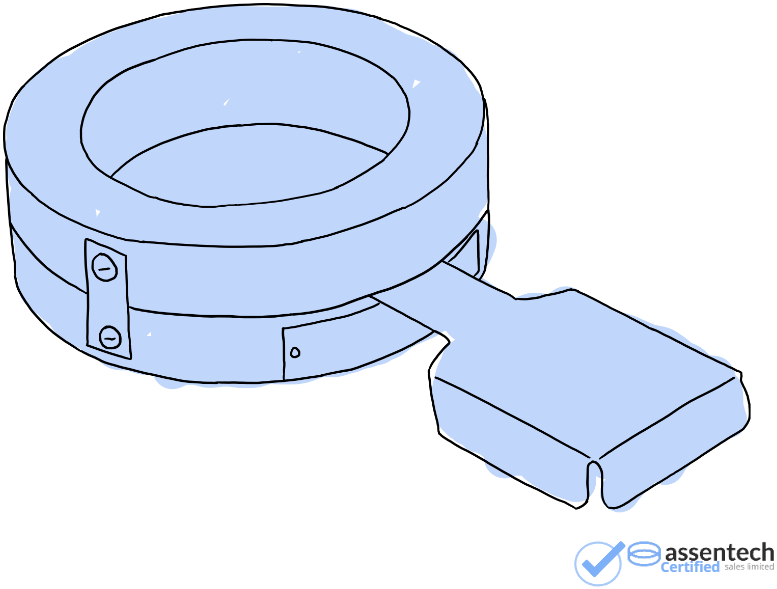

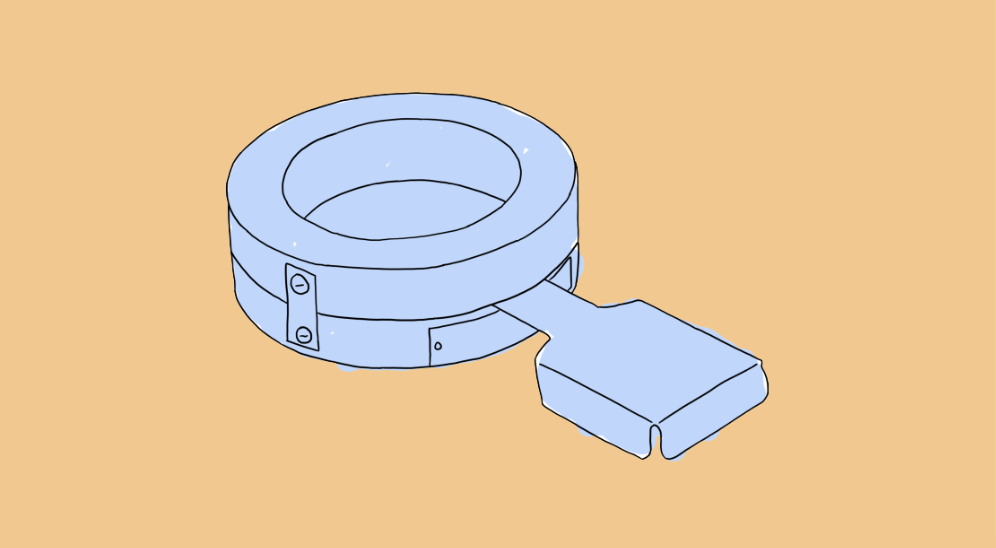

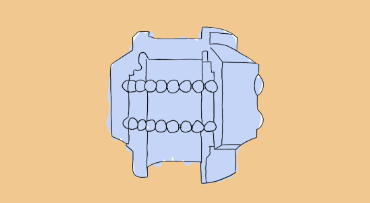

Bursting discs and holders are crucial components in a wide array of pressure and vacuum-related operations, playing a pivotal role in ensuring system integrity and safety under varying operational conditions. These discs, often paired with a holder, are engineered to rupture at a predetermined pressure or vacuum, allowing for immediate pressure relief during critical operations. This functionality is key not only for maintaining internal pressure within safe limits but also for preventing potential damage to system components and mitigating the risk of operational failure.

Moreover, bursting discs play a significant part when pressure adjustment is required due to changes in system or environmental conditions. By offering this dual functionality, bursting discs contribute substantially to the longevity and reliability of various systems, acting as a protective shield against unwanted pressure changes that could otherwise jeopardise both the system’s integrity and the safety of personnel.

Bursting discs and holders, due to their economical, compact, maintenance-free, and bubble-tight characteristics, are a practical and reliable choice for managing your system’s pressure needs. We also offer a selection of accessories to optimise the performance of your bursting disc assembly under different environments. At Assentech Sales Limited, our wide range of holder types, styles, and materials are designed to meet your unique requirements and provide the utmost safety and efficiency.

Types of Bursting Discs we Supply

- Reverse-Acting: Our bursting disc functions optimally in situations where pressure instabilities in the dome lead to its reversal or buckling. Compared to forward-acting designs, it offers a longer cycle life due to the compressive nature of the stresses in reverse-acting discs, which do not promote crack propagation. To ensure stability, the dome is supported on the outlet side, preventing premature movement prior to reversal. Scoring or cutting techniques are employed to facilitate opening after this reversal. The opening technique employed correlates with the energy present during reversal, with vapour reversal being significantly more energetic than liquid reversal.

- Forward-Acting: Functions can be compromised when the most vulnerable part of the disc surpasses its tensile strength. This is because, at higher operating ratios, these functions generally have a limited fatigue life. The primary reason behind this finite life is the tensile nature of the stresses they encounter. Additionally, their capability to withstand vacuum or back pressure is contingent on several factors. These include the inlet diameter that supports the dome, the prominence of the bulge, the material’s thickness, and sometimes, the incorporation of additional vacuum support.

Compliance with International Standards

Our products adhere to leading international standards for pressure relief. At the primary level, they are compliant with EN ISO 4126-2 CE and ASME XIII(UD). Beyond these benchmarks, we abide by varying international standards, highlighting our steadfast commitment to ISO9001. Moreover, we have ensured regional compliance through certifications such as the KOSHA, Canadian Registration Number (CRN), China Safety Notice, Stoomwezen, and TUV. These certifications not only reinforce our dedication to safety but also signify our aim to meet the highest quality standards across the globe.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

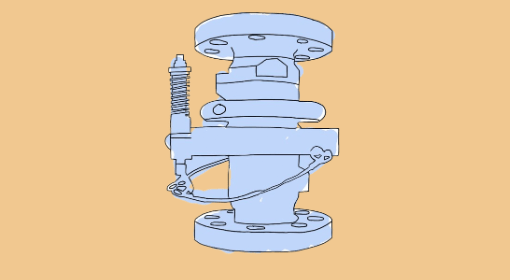

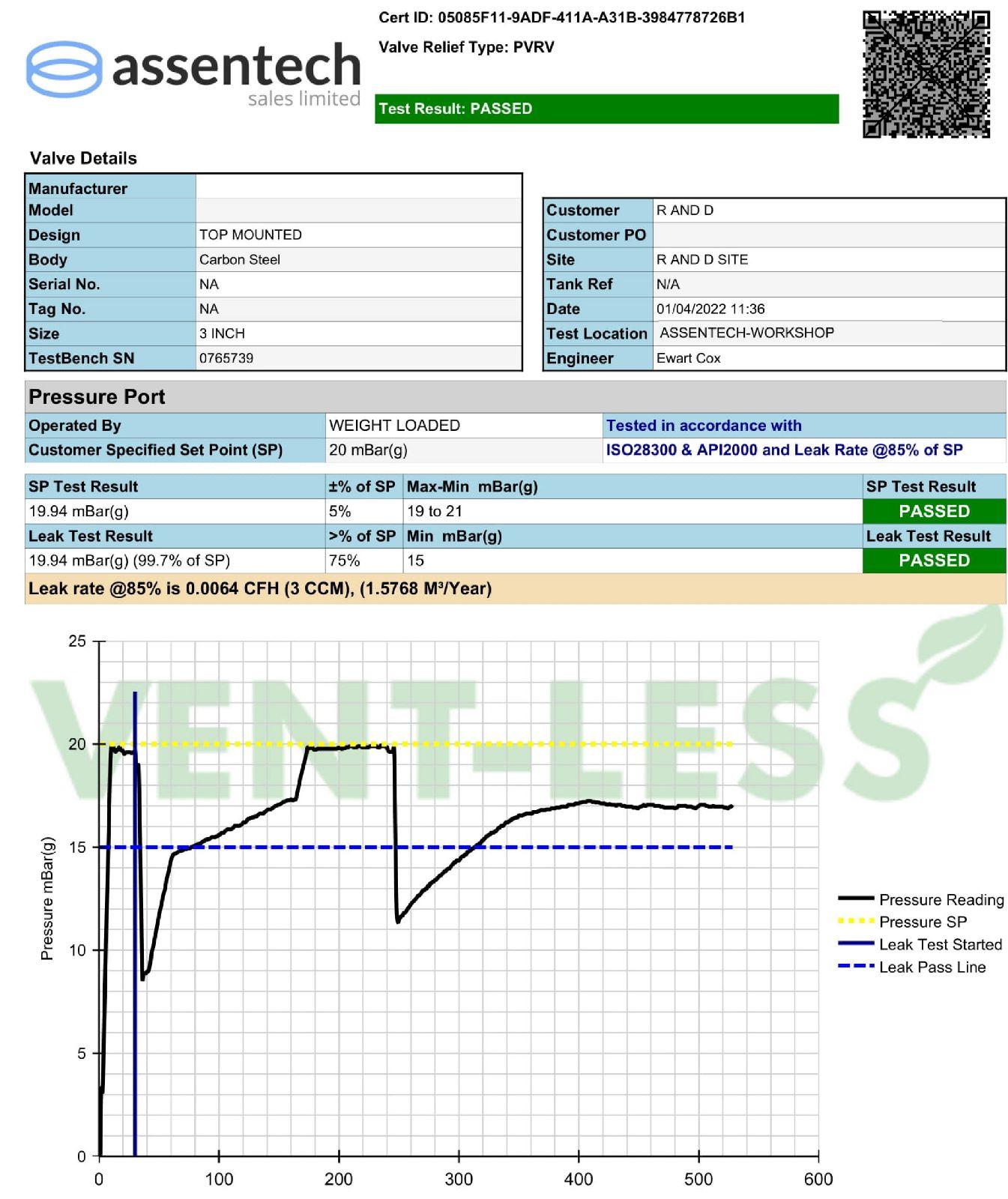

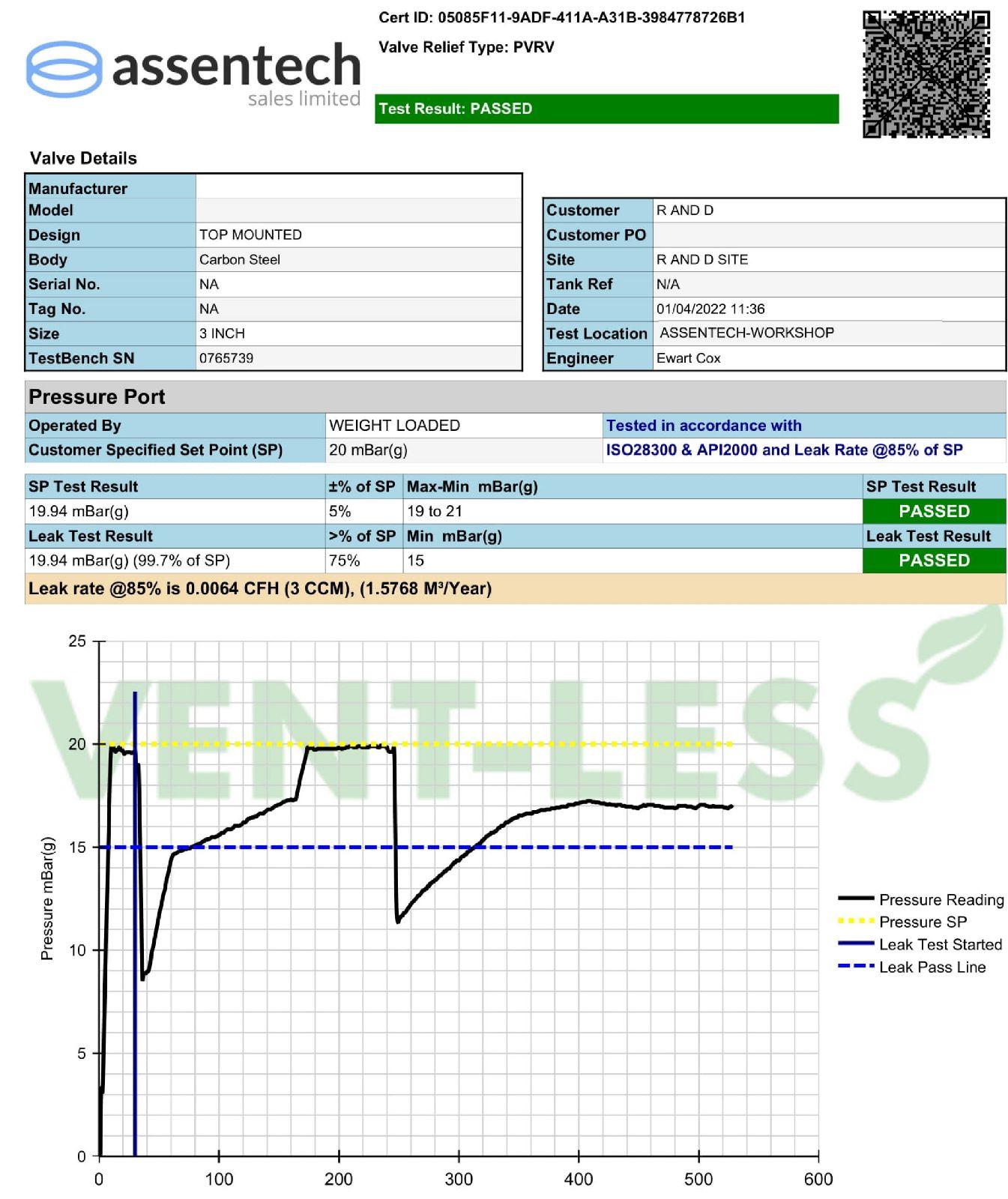

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.

Process Safety Equipment Product Range

Bursting Discs

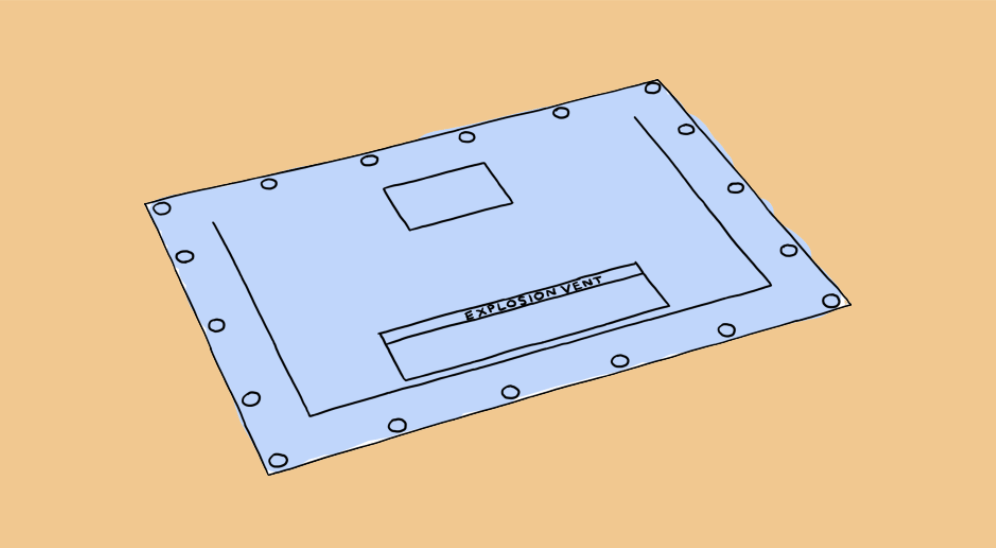

Burst Panels

Swivels

Break-Away Couplers

Rack monitors

Assentech Academy - Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact