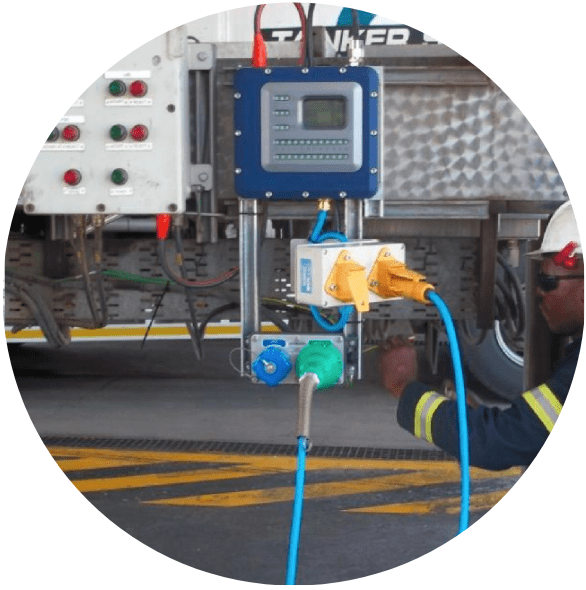

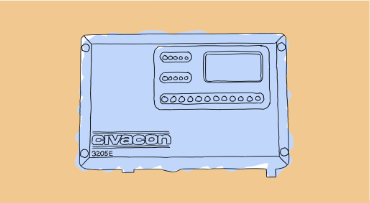

At Assentech Sales Limited, we are proud to offer the OPW CIVACON 8870.

The OPW Civacon 8870 Series Overfill Prevention and Ground Verification Controller is the industry leader. It provides confidence at ground level and safety you can verify.

When it comes to bottom loading operations, safety hinges on one simple question: Is the system safe to load?

The OPW CIVACON 8870E Overfill Prevention and Ground Verification Controller exists to provide a clear, reliable answer before any product moves. Designed for API bottom loading applications on single and multi-compartment tank trucks at storage depots, it combines continuous grounding verification and overfill protection to ensure loading can only proceed when conditions are genuinely safe.

This is not just an overfill monitor. It is a critical control point that protects people, assets, and the environment.

| Comparison: Civacon 8870E vs Popular Competitor | ||

|---|---|---|

| Feature / Capability | OPW Civacon 8870E | Popular Competitor Rack Monitor |

| EN 13922 compliance | Yes – designed to meet the Standard | Model dependent |

| Ground verification | Continuous, self-checking (static bonding) | Basic continuity based |

| Overfill prevention | Yes, fail-safe | Yes |

| Dual circuit fail-safe architecture | Yes – aligned with EN 13922 fail-safe principles | Typically no |

| Redundant output relays | Yes (dual redundant) | Typically single relay |

| Sensor technology support | Automatic recognition of 2-wire and 5-wire Optic Sensor Technology | Usually fixed per unit |

| Fault detection | Open circuit, short circuit, wiring faults | Limited fault visibility |

| Operator interface | Graphic pictogram display | Basic LEDs |

| Event history logging | Yes | No |

| Response time | < 200 milli seconds | Typically slower |

| Operating temperature range | -45°C to +70°C | Narrower range |

| Integration readiness | Terminal automation ready | Limited |

| Safety philosophy | Verified and enforced | Indication based |

Why ground verification matters

The transition to bottom loading eliminated many risks associated with working at height, but it introduced others.

Incorrect grounding, sensor faults, wiring degradation, or bypassed safety systems can turn a routine loading operation into a serious incident involving fire, spill, or exposure.

The 8870E continuously verifies that the tanker, sensors, and system are safe before loading starts and throughout the operation. If any condition is unsafe, loading does not proceed.

No assumptions.

No workarounds.

No silent failures.

Compliance with EN 13922

The CIVACON 8870E is designed and manufactured to comply with EN 13922 — the recognised European Standard for overfill prevention and ground verification systems used during loading and unloading of road tankers carrying flammable liquids.

EN 13922 defines the functional safety requirements for:

- system integrity

- fault detection

- fail-safe operation

- interface compatibility between loading rack and vehicle.

The 8870E aligns with this Standard by:

- verifying correct grounding prior to and during loading

- continuously monitoring overfill sensors and circuit integrity

- detecting short circuits, open circuits, and wiring faults

- preventing loading when unsafe or non-compliant conditions are detected

Compliance with EN 13922 ensures the system is not only operationally effective, but also aligned with recognised best practice for preventing overfill events and ignition risks at loading racks.

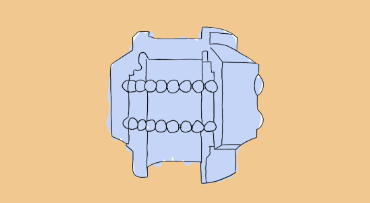

What the 8870E verifies

The CIVACON 8870E controller integrates multiple safety checks into a single robust unit:

- Ground connection verification

- Overfill sensor presence and integrity

- Open/short circuit detection

- Fault condition identification

- Clear visual status and diagnostic indicators

- Fail-safe permissive outputs to rack automation systems

These verifications are ongoing and automatic, removing reliance on human interpretation or intermittent checks.

Designed for real world operations

The 8870E is built for demanding industrial loading environments:

- ATEX compliant for hazardous areas

- Supports multiple sensor configurations

- Automatic recognition of connected sensor types

- Intuitive status indicators for rapid operator understanding

- Operation across wide temperature ranges

These features make it suitable for high throughput terminals where clarity, speed, and

reliability are essential.

Why this matters beyond compliance

Ground verification is not just about ticking a standard.

It is about preventing overfill events before they occur and eliminating unsafe conditions at the point of load initiation.

A properly functioning 8870E:

- reduces reliance on procedural controls alone

- protects operators from exposure and ignition risk

- prevents product loss and environmental impact

- supports defensible safety and compliance positions

When incidents occur, the defining question is seldom what failed — it is what was assumed to be working.

The OPW CIVACON 8870E removes that uncertainty.

Why the OPW Civacon 8870E sets the benchmark

The OPW Civacon 8870E Overfill Prevention and Ground Verification Controller is widely recognised as the benchmark for rack monitoring because it does more than indicate status. It verifies safety, detects faults, and enforces fail safe operation at the point of loading.

Unlike basic rack monitors that rely on continuity checks and permissive signals, the 8870E continuously validates that all critical safety conditions are met before and during loading. If conditions are unsafe, loading simply cannot proceed.

What makes the difference is depth of verification, clarity for operators, and defendable compliance.

What truly sets the OPW Civacon 8870E apart

- True fail safe architectureDual redundant output relays for both overfill prevention and ground verification ensure that any detected fault results in an immediate and safe shutdown.

- Continuous ground verificationIncluding self checking of the cable and plug assembly, rather than a one time continuity check.

- Automatic sensor recognitionSeamlessly supports and switches between 2-wire optic and 5-wire optic sensor technologies without manual configuration.

- Advanced fault detectionIdentifies open circuits, short circuits, wiring faults, and unsafe conditions that basic systems do not detect.

- Clear, multilingual pictogram displayThe graphic LC display uses icons and symbols rather than text, making system status and fault conditions immediately understandable regardless of language, literacy level, or operator experience. This significantly reduces misinterpretation and response delay at busy loading racks.

- Detailed diagnostics and event loggingFaults are visible, recorded, and traceable rather than hidden, supporting investigations, maintenance, and continuous improvement.

- EN 13922 compliant by designFully aligned with the recognised European Standard for overfill prevention and ground verification systems, supporting defendable regulatory compliance.

- Designed for harsh environmentsProven operation from -45°C to +70°C, making it suitable for demanding terminals and high throughput operations.

- Dual circuit fail-safe architecture (in SIL-2 version)Two independent safety circuits must agree before a permissive to load is given. This ensures that a single fault, relay failure, or wiring issue cannot falsely indicate a safe condition, forcing the system into a safe state if any discrepancy is detected.

Why this matters in practice

Most loading incidents do not occur because safety systems are missing. They occur because a system appeared to be working while a fault went undetected. Basic rack monitors indicate. The OPW Civacon 8870E verifies. That distinction reduces the likelihood of overfill events, ignition hazards, and unsafe loading conditions, while giving operators clarity, engineers confidence, and organisations measurable, defendable safety.

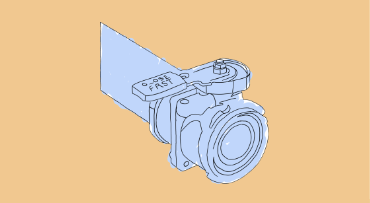

Useful accessory

OPW Civacon 7454E / 7154E Smart Storage Hanger, helps to ensure safe storage of plug and cable assemblies when not connected to the vehicle. Whilst in stored position it verifies the plug is properly seated and the pin connections are intact. Possible cable issues are detected. It protects against dirt and water ingress thus enhancing the life time of the plug. Optionally the AUX-2 relay of the 8870E can be activated at detection of the Smart Storage Hanger for positive identification of parked plug and positive identification of functional plug pins.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Bottom Loading Arms

Top Loading Arms

Swivels

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Couplers and Adaptors

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact