BREATHER VALVE SERVICE, SPECIALIST, AND INSPECTION PACKAGES ENSURING COMPLIANCE, PROCESS SAFETY, AND RISK‑BASED ASSET INTEGRITY.

↠ SEE WHAT CAN GO WRONG WITH YOUR BREATHER VALVES

| What Might Go Wrong | What We Do | What It Proves |

|---|---|---|

| Weights added to an installed breather valve pallet in an attempt to reduce leaks and odours | In-situ inspection and verified set point review to confirm true opening pressure and vacuum | Confirms no unauthorised alteration and that the valve lifts at the correct setting |

| The valve being dropped in transit impacting functionality | Pre commissioning functional API2000 testing before installation plus physical inspection | Confirms no hidden mechanical damage, functions in accordance to nameplate and API2000 compliant |

| The valve set incorrectly from the outset | API 2000 testing to verify actual set pressure and vacuum settings. Good pre-commissioning discipline | Confirms settings align with specification and nameplate including API2000 compliance |

| The nameplate not aligned with the specification | API2000 test to cross check of nameplate against design requirement and operating duty | Ensures installed valve matches engineering specification and complies to API2000 |

| The soft goods kit not suitably compatible with the media | Material compatibility review and controlled replacement soft goods kits | Prevents degradation, swelling or poor sealing due to media interaction |

| The breather valve incorrectly sized due to media or duty changes | Health check reviewing fill and empty rates, stored media and vent configuration | Confirms suitability for actual operating conditions. Complies with EEMUA231 |

| The breather valve leaking excessively due to no testing from new, poor ageing asset management or poor design | Leak rate measurement in accordance with API 2000 and performance verification | Provides quantified leak rate and evidence of emission reduction and PASS or FAIL to API2000 |

| The weights package not suitable for the media, for example lead weight in food, drink or pharmaceutical application | Engineering review of materials, compatibility and suitability for service for customer due diligence | Confirms compliance with hygiene, safety and media requirements |

| The pallet imbalanced causing a leak path | Internal inspection and controlled reassembly followed by API2000 testing | Ensures proper seating, sealing integrity and API2000 compliance |

| Poor quality soft goods preventing suitable sealing | Replacement with verified quality components and post service API 2000 testing | Confirms restored sealing performance and API2000 compliance |

| Transit packaging left inside impairing functionality | Internal check plus pre commissioning API2000 testing to check functionality | Confirms valve is obstruction free and fit for service and is safe plus compliant |

| Valve assembled incorrectly from new or after servicing | Physical check and API2000 test to check safe functionality and accurate settings | Confirms mechanical integrity and correct assembly plus API2000 compliance |

| Valve specified incorrectly, wrong size, materials or design | Full health check and application review | Reduces risk of failure, downtime, incidents and non compliance |

| Name plate missing or painted over. This is an automatic FAIL | Verify settings with an API2000 test and full health check, supply new nameplate | Aligned to application and suitability of service. API2000 compliant. Asset tagging for traceability and confirmation of settings |

| Wildlife inhabiting or trapped inside the valve body | Removal of trapped wildlife. Visual inspection of internals. Reassembly followed by API2000 testing. Recommend security improvement. | Management of aging plant. Risk mitigation steps. Proof of retest and API2000 compliance. Wildlife protection. |

| Seals damaged by manual lifting of the pallet to stop sticking | Replace seals with verified quality and same as original specification. Physical inspection. Post service API 2000 testing. More frequent inspection | Evidence of remedial steps, successful management of aging plant and proof of API2000 compliance |

| Seals damaged by chattering pallet caused by oversize valve | Calculate venting requirements to API2000 and recommend changes to stop chattering | Confirms valve repair, competent asset management with evidential API2000 compliance |

Inspection and Verification

- Frequency: Typically annual, but determined by site-specific risk assessments.

- Service: In-situ inspections (valve remains on tank).

- Activities: Inspect for corrosion, deterioration, and tampering; provide advisories, photographic evidence, and detailed observations.

- Verification: Reverse engineering of settings to confirm valve integrity and highlight any historical tampering concerns.

Commissioning Check

- Verify that the breather valve is correctly set before installation on high value or high risk storage tanks.

- Confirm safe and accurate function and proof you have checked.

- Mitigates risk of packaging materials remaining, transit damage or pallet imbalance.

- Verify, measure and prove leak rates are within acceptable limits.

- Document compliance with API 2000 standards to provide evidence for safe installation and regulatory assurance.

TEST BEFORE YOU BUY!

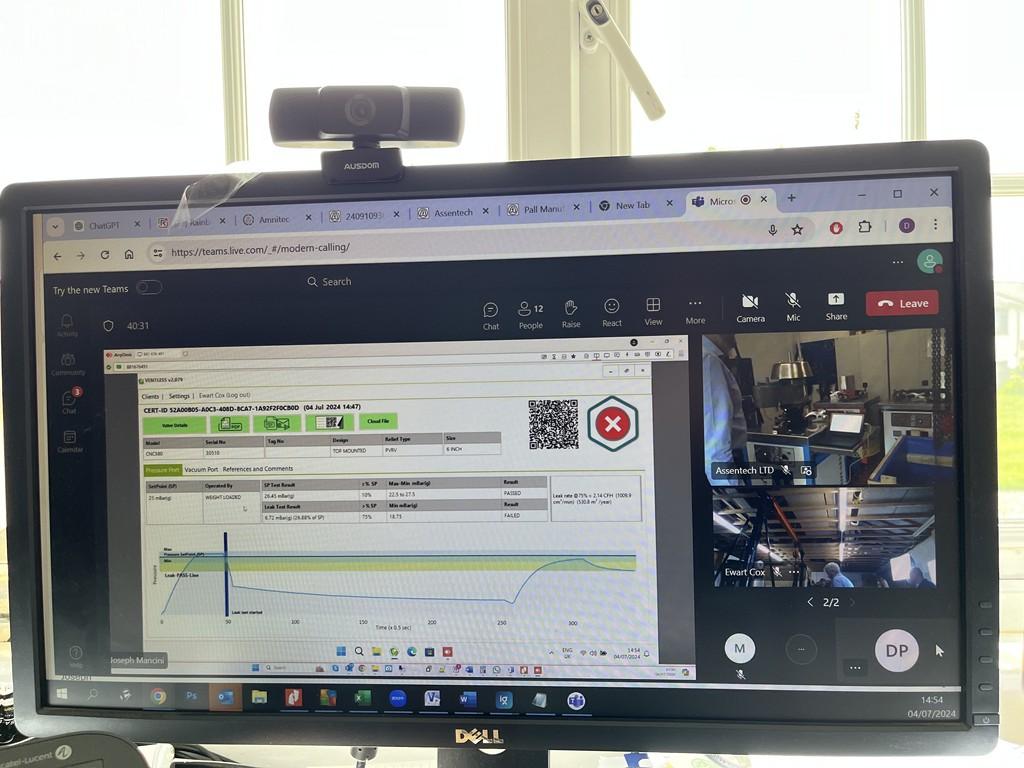

Assentech offers Remote Factory Acceptance Testing (FAT) for your tank or digester breather valves

Customers are seeing the benefit of specifying payment terms in their purchase orders with breather valve manufacturers or suppliers, where payment is only due once the valve successfully passes a Remote Factory Acceptance Test. This test is conducted using a regulatory approved Best Available Technique, Vent Less, to independently verify compliance with API2000 and ISO28300.

How It Works:

You send your breather valve(s) to Assentech, and you witness the entire process remotely. You see the valve being taken out of the crate by our test technician and placed onto the Vent-Less test bench. There are three simultaneous video feeds to ensure full transparency:

- One shows the Vent-Less test bench in operation

- One shows the Vent-Less software screen with live measurement data

- One shows the test technician conducting the test

This setup ensures the results are fully transparent and verifiable, with live data available to you at the same time as our technicians, eliminating any doubt of falsification.

The FAT is conducted using Vent-Less, recognised as Best Available Technique (BAT), and covers:

- Verification of valve settings

- Measured leak rate on both vacuum and pressure ports

- Compliance with API2000 and ISO28300

- Safe operational functionality

- Confirmation that performance matches the valve nameplate

Instantaneous certification is generated at the end of the test, providing detailed evidence of all the above. This certification serves as irrefutable proof for your review, compliance records, and is accepted by Regulators.

This ensures that your valve is compliant, safe, and correctly set before you pay, and provides required data for IED, Appropriate Measures 8.11 & 11.8, Regulation 61, and LDAR, as well as for OGMP, EEMUA 231, Environmental Reporting, and Improvement.

Servicing and API 2000 Testing

- Frequency: Typically every three years, or earlier, determined by site reviewing application risks.

- Process: Valve removed, decontaminated (MSDS provided), serviced with new compatible OEM soft goods kits installed.

- Testing: API 2000 testing to prove and verify settings, leak rate, emission reduction, and safe functionality.

- Evidence: Pre and Post-service API 2000 test demonstrates improvement, confirms compliance, and provides documented proof of due diligence and safe operation.

- Options: Onsite or Assentech workshop service; "swap-in/swap-out" valves available to maintain tank protection continuity.

Breather Valve Health Check (Data Capture)

- Objective: Verify installed pressure/vacuum relief devices are appropriate for actual operating conditions.

- Scope: Evaluates venting equipment against fill/empty rates, stored media, venting configuration, and historical performance.

- Standards Referenced: API 2000, ISO 28300, EEMUA 231, API 650, EN 14015.

- Outcome: Moves beyond assumed compliance, providing documented, evidence-based confirmation of valve performance for safe operation, asset integrity, and regulatory audits.

Specialist Services

- Regulatory and compliance advice.

- Written Scheme of Examination for each valve.

- Valve sizing for operational conditions.

- Multi-product packages for complex applications.

- Breather Valve API 2000 / ISO 28300 Test Reports.

- Supporting compliance with EEMUA 231.

- LDAR Audits: onsite leak source surveillance, reporting, and breather valve repair.

- Tank venting risk assessment and corrective measures.

- Consultancy support for HAZOP reviews.

- Regulation 61 emission source detection surveys with OGI technology (Method 21 compliant).

Vent-Less Test Bench Range (to buy or hire)

- Purpose: High-accuracy API 2000 automatic testing.

- Technology: Proprietary Vent-Less innovation, recognised as Best Available Technique (BAT) with approved test reports; globally installed and award-winning.

- Options: Fixed or mobile benches.

- Fully traceable data.

-

API2000 Testing Protocol (AI-driven):

- Verify valve settings

- Test vacuum and pressure ports

- Measure leak rates

- Confirm safe functionality and emission control

- Efficiency: Single-operator; no prior knowledge necessary, tests as fast as 3 minutes for smaller valves.

- Outputs: Instant photographic certification, documented results, QR code access to secure online portal.

- Benefit: Early identification of at-risk valves or VOC emissions, supporting informed operational decisions, compliance, and best-practice.

SPECIALIST MAINTENANCE

- Onsite/Offsite Technical Advice and Support of Complex and Challenging Tank Storage, Fluid Transfer or Process Safety Applications (Industry Expert)

- Technical Support and Evaluation Specialists

- Internal Floating Roof (IFR) Supply, Supervisor Support, and Installation Packages (Factory Authorised)

- Loading Arm Supply and Maintenance

- Epsilon Coupler Supply , we also provide inspections, pressure testing, full overhauls, seal replacement,condition reporting, and Certification (Factory Authorised)

- Site Asset Registering with Tank Venting Tables

TRAINING COURSES

- Learn how to operate and understand the functionality, features, and measurement controls of the OPGAL OGI Camera, compliant with Method 21. (Industry Expert)

- Learn from Industry Leaders: Hands-On Training in Breather Valve Servicing and Testing in accordance with API2000 Section 5.4 / ISO28300 Section 6.4 to reduce emissions, improve safety and evidence compliance. (Industry Expert)

Authorised Service Centre

Assentech is an authorised service centre with specialist-trained technicians for servicing, testing, and certifying equipment from OPW Fluid Transfer, Protego, 3B, Groth, and Matrix Applied Technologies. We also have access to OEM spares, technical support, and official dealer service procedures.

Project and Installation Experts

We design, supply, install, and service Geodesic Domes, Internal Floating Roofs, and Loading Arms.

Why Customers Choose Assentech

- The innovators, designers and suppliers of the groundbreaking Vent-Less test bench and recognised Best Available Technique for accurate, repeatable API 2000 testing

- Collaborative support to evaluate service frequency as part of Written Scheme of Examination for individual breather valves

- Evidential evidence on performance, function, accuracy and leakage with Irrefutable accuracy with nationally traceable calibration

- Supports compliance to COMAH, DSEAR, IED etc

- Access to factory support, original build specifications and OEM spares

- Historical service records retained for every valve to identify repeat offenders and short longevity

- Expert support for complex or troublesome applications

- Leak rate measurement and emissions quantification for pressure and vacuum ports

- Industry recognised breather valve specialists with a strong record of successful testing

- Clear photographic, accurate data and advisories

- Proven reduction in emissions, risk and product loss

Get in Touch

“An easy way to mitigate exposure, ensure your facility is safe at all times and ease stress with shutdown planning”

How can I Book my Maintenance and Inspection?

Booking a Maintenance and Inspection could not be easier!

Either send your equipment to our workshop, or we can visit your facility.

Complete our contact form, email us on info@assentech.co.uk, or give our friendly team a ring on +441726844707

One of our skilled team will get back to you within 2 working days.