In the fast-paced world of loading systems, optimal performance, swift operations, and safety stand at the forefront. When investing in such critical systems, commercial value extends beyond just capital investment—it encompasses on-going operational costs, user-friendliness, and easy maintenance.

At Assentech, we proudly represent OPW Engineered Systems, a global leader in quick and dry disconnect fittings. OPW products offer unparalleled peace of mind, combining decades of experience, superior quality, and value for money over the long term.

OPW’s expertise in mitigating fluid handling risks across diverse industries is internationally recognised. Their products have proven their mettle at major oil loading-unloading terminals globally, making them a trusted choice for an array of applications.

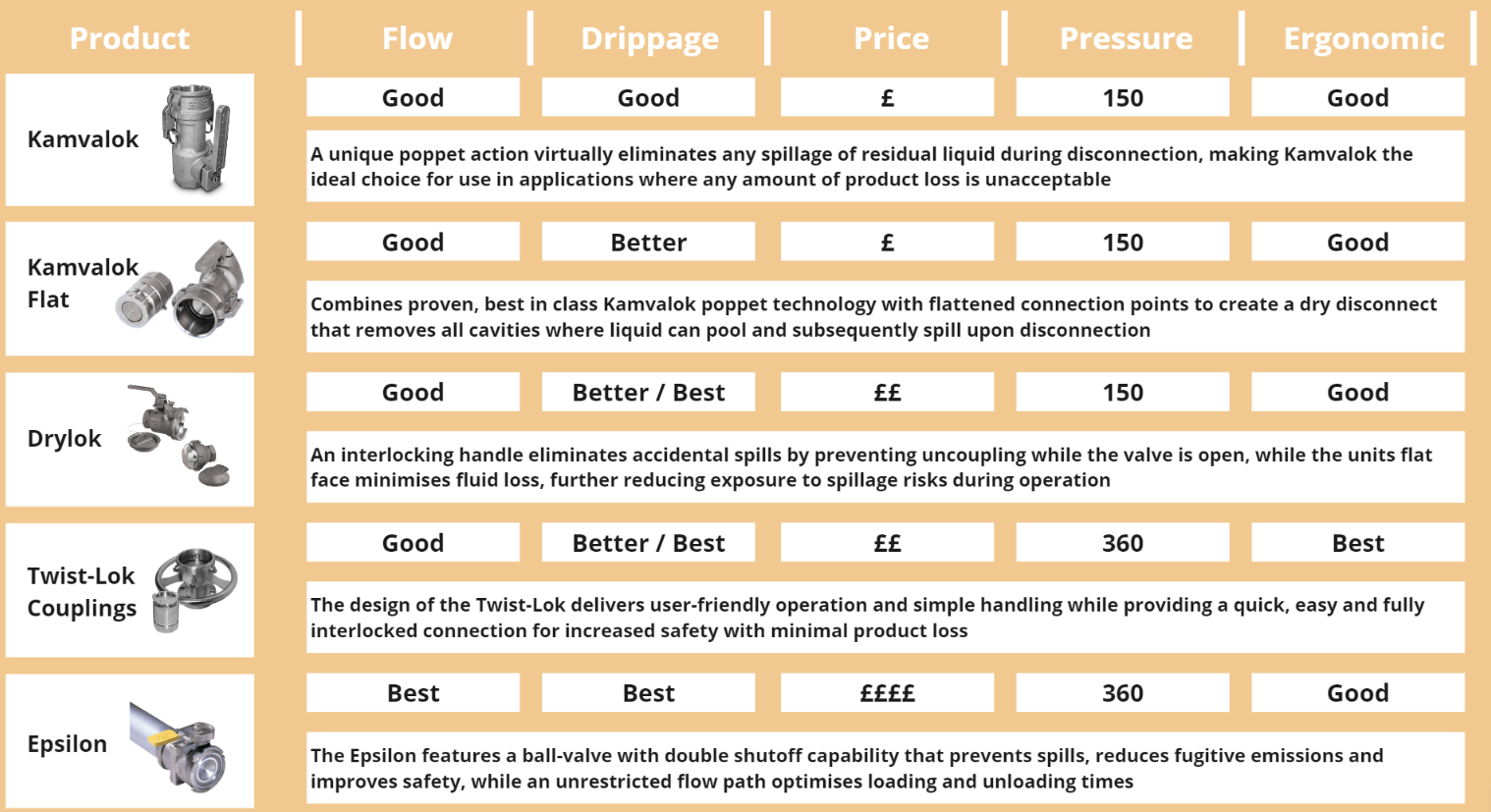

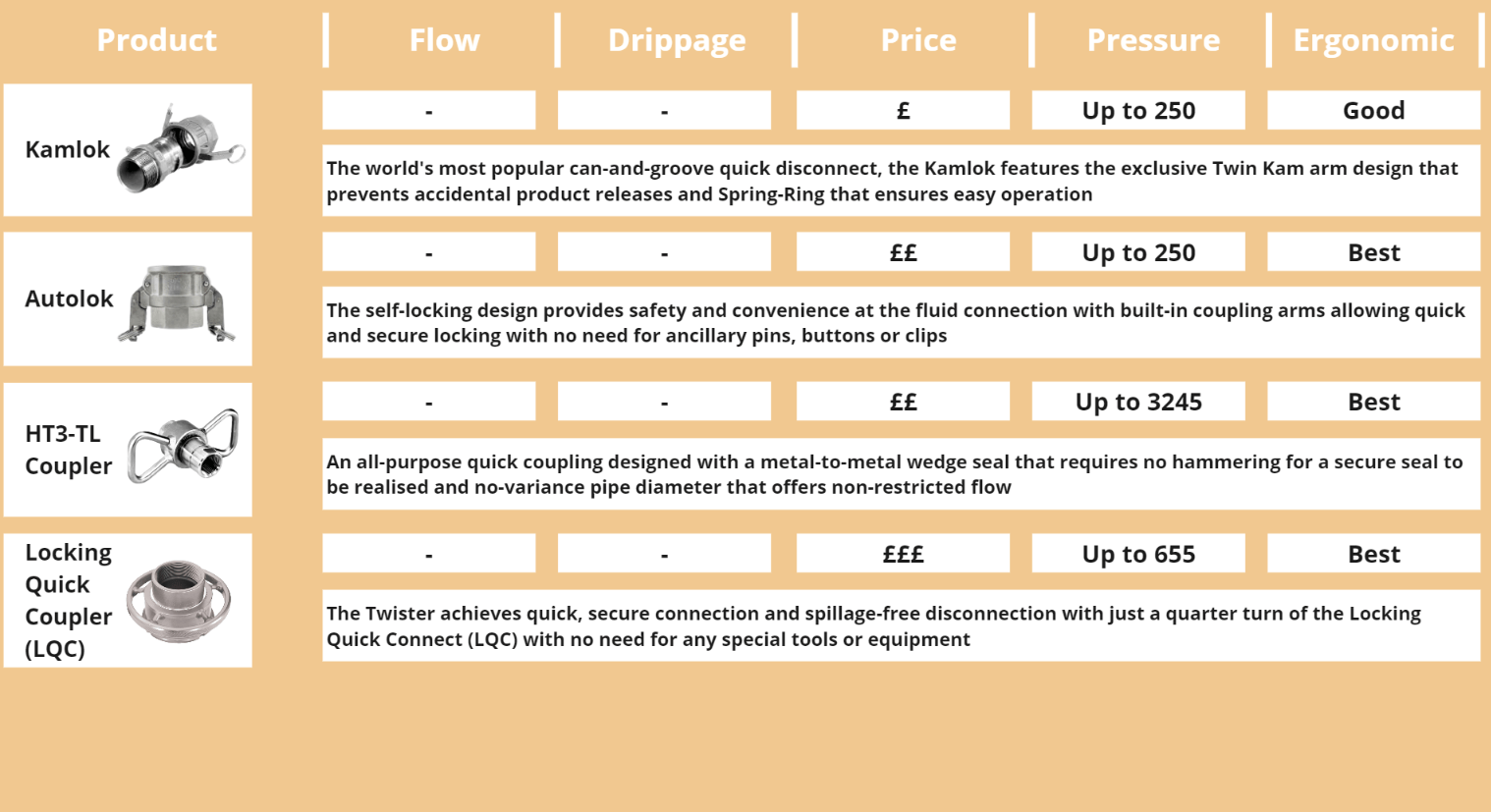

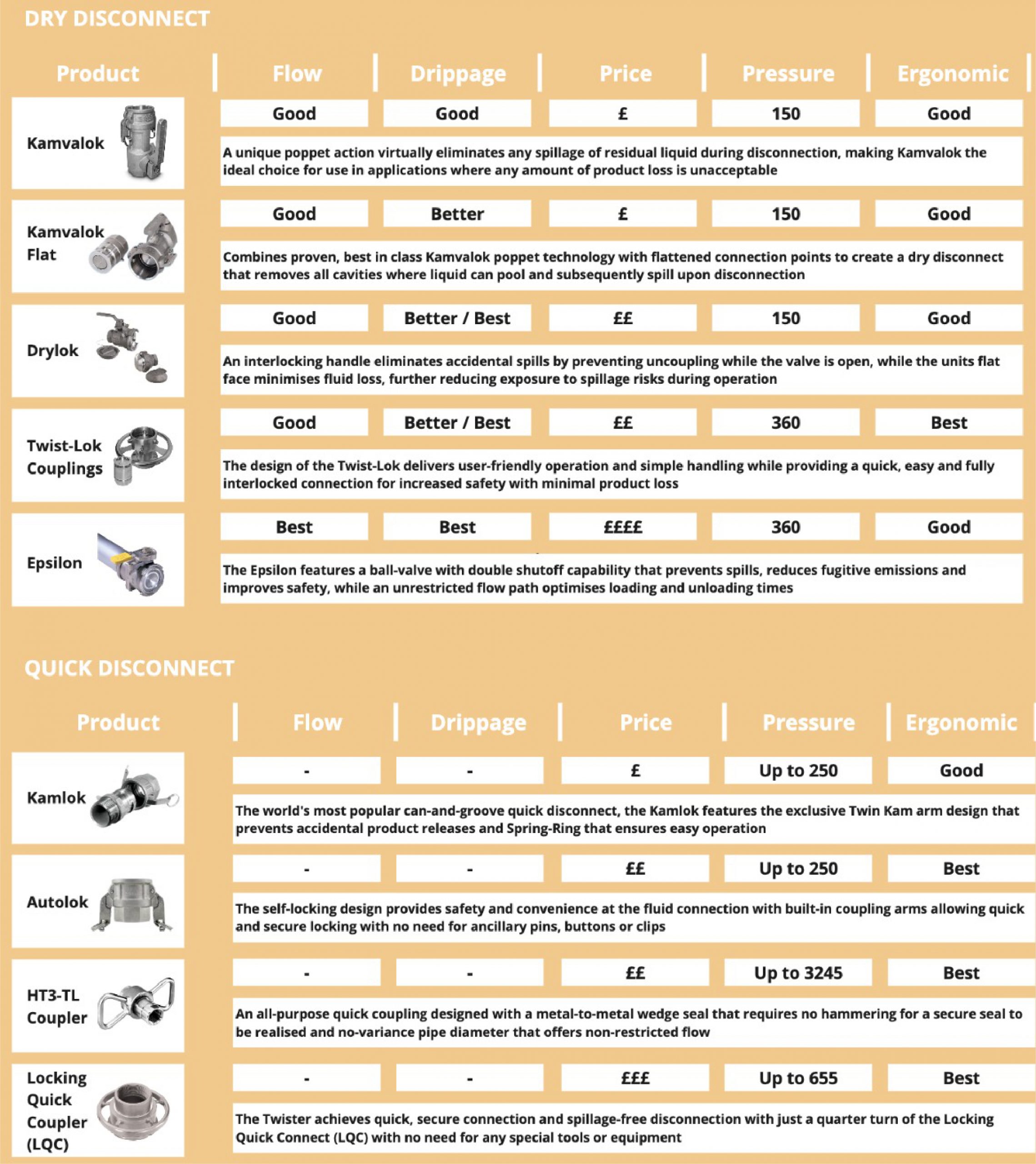

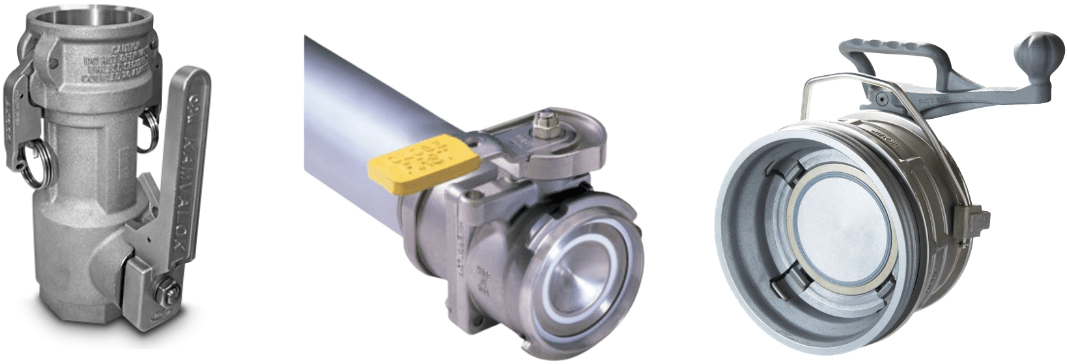

We bring to you an extensive array of connection options. For immediate disengagement needs, the Kamlok® and Autolok® quick disconnects are available. For situations demanding a dry disconnect, we provide options such as Kamvalok®, Drylok™️, and Epsilon®, all adept at handling a wide spectrum of hazardous liquid applications.

For the most demanding sealing requirements involving extreme pressure and temperature, the Hiltap™️ brand offers cutting-edge, high-performance couplings and connectors. Trust in Assentech Sales Limited and OPW Engineered Systems to deliver the highest quality solutions for your fluid handling needs

Types of Couplers we Supply

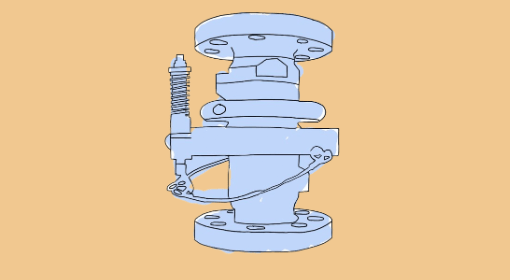

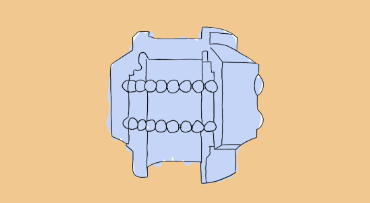

- API Coupler: API Couplers are designed for a safe, spill-free, and effortless bottom loading experience, combining top features of API couplers and incorporating new elements for enhanced user-friendliness, proven successful at major oil terminals worldwide, and they are easily disassembled with just a screwdriver, enabling quick maintenance without special tools.

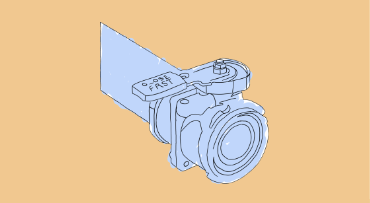

- Kamvalok: The industry standard, are used at liquid-transfer points to reliably prevent product loss and spillage during connection or disconnection.

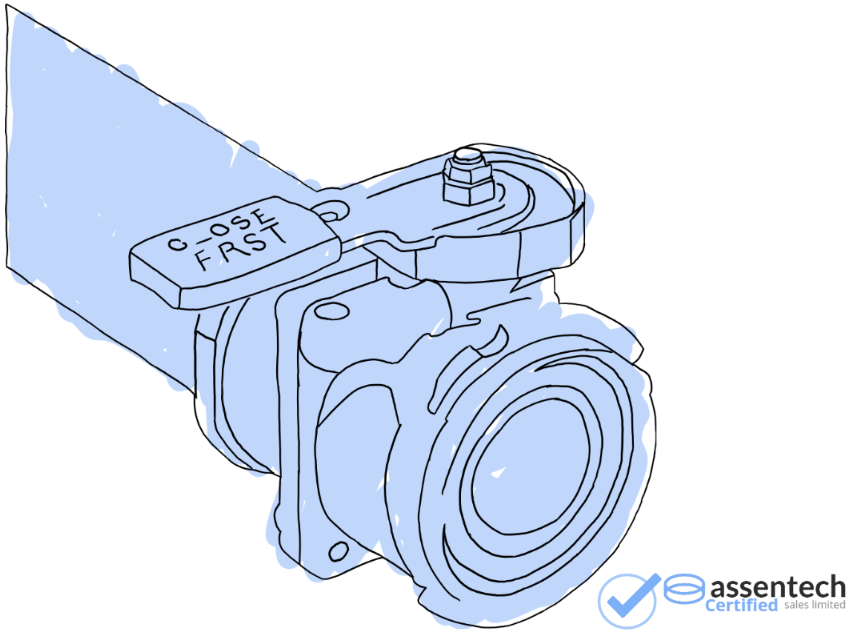

- 🏆 Epsilon Coupler: Features a double ball valve system, aims to prevent chemical spills, reduce emissions, enhance safety and environmental compliance, and cut costs, making it particularly suitable for pharmaceutical and sanitary applications.

- Drylok Dry Disconnect Coupler & Adaptor: Designed to safely transfer hazardous corrosive, volatile liquids like acids, solvents, and petrochemicals, features an interlocking handle to prevent accidental spills and a flat face to minimise fluid loss, making it ideal for handling hazardous fluids where product loss is a problem, such as in high-pressure lines, high flow rates, slurries, and gases.

- Twist-Lok Dry Disconnect Couplings: The latest addition to the Dry Disconnect Couplers range, offers user-friendly operation and simple handling for a quick, easy connection with minimal product loss.

- Stop-Lok Multi-Application Coupler: Available in sizes from 3/4 to 3 inches, is constructed of 316 stainless steel and operates in temperatures ranging from -20oF to 400oF, enabling quick connection of pipe and hose for efficient loading and unloading.

| Epsilons: The Superior Choice and Why |

Epsilons: The Superior Choice and Why

OPW’s Epsilon Couplers are the epitome of innovation and reliability in the fluid transfer technology sector. These couplers are celebrated for their robust construction, unparalleled safety features, and extraordinary leak-tight performance, making them the superior choice in the market.

One of the key unique selling points of Epsilon Couplers is their interlocked dual ball valve full bore design, which allows for maximum flow rate, enhancing productivity. They also feature minimal dead space, ensuring no spillage upon disconnection, a critical feature for maintaining cleanliness and safety in your operations.

These compact and lightweight couplers are the number one product for highly toxic and dangerous applications. This is due to their design, which includes interlocked handles that prevent opening when the couplers are already open, thereby reducing the risk of accidental spillage or exposure to harmful substances.

For additional safety, Epsilon Couplers can be keyed, providing an extra layer of security and preventing unauthorised access or use. They are designed to withstand extremely high pressures of up to 435 psi (30 Bar) and temperatures up to 450°F (230°C), making them suitable for the most demanding industrial applications.

Every Epsilon Coupler comes with a unique serial number, ensuring traceability. This feature is particularly useful for quality control and maintenance purposes, as it allows for easy identification and tracking of each unit.

The durability of Epsilon Couplers, combined with their easy maintenance and serviceability, leads to significant cost savings over time. They are designed to withstand rigorous usage while ensuring maximum productivity, providing seamless operation that’s second to none.

Choose OPW’s Epsilon Couplers for a truly efficient and reliable fluid handling solution. Their innovative design and superior features make them an investment that pays off in safety, efficiency, and long-term cost savings.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

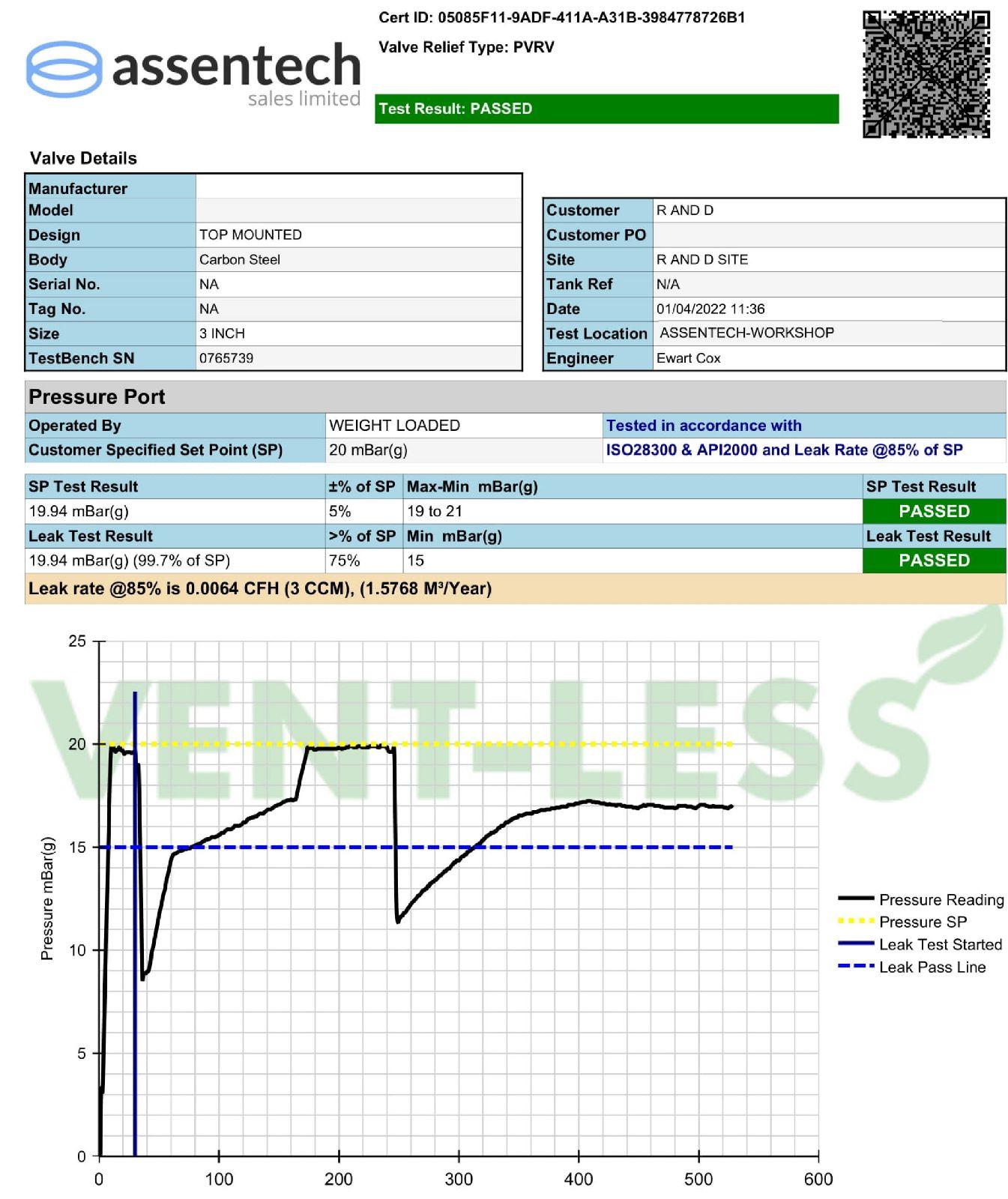

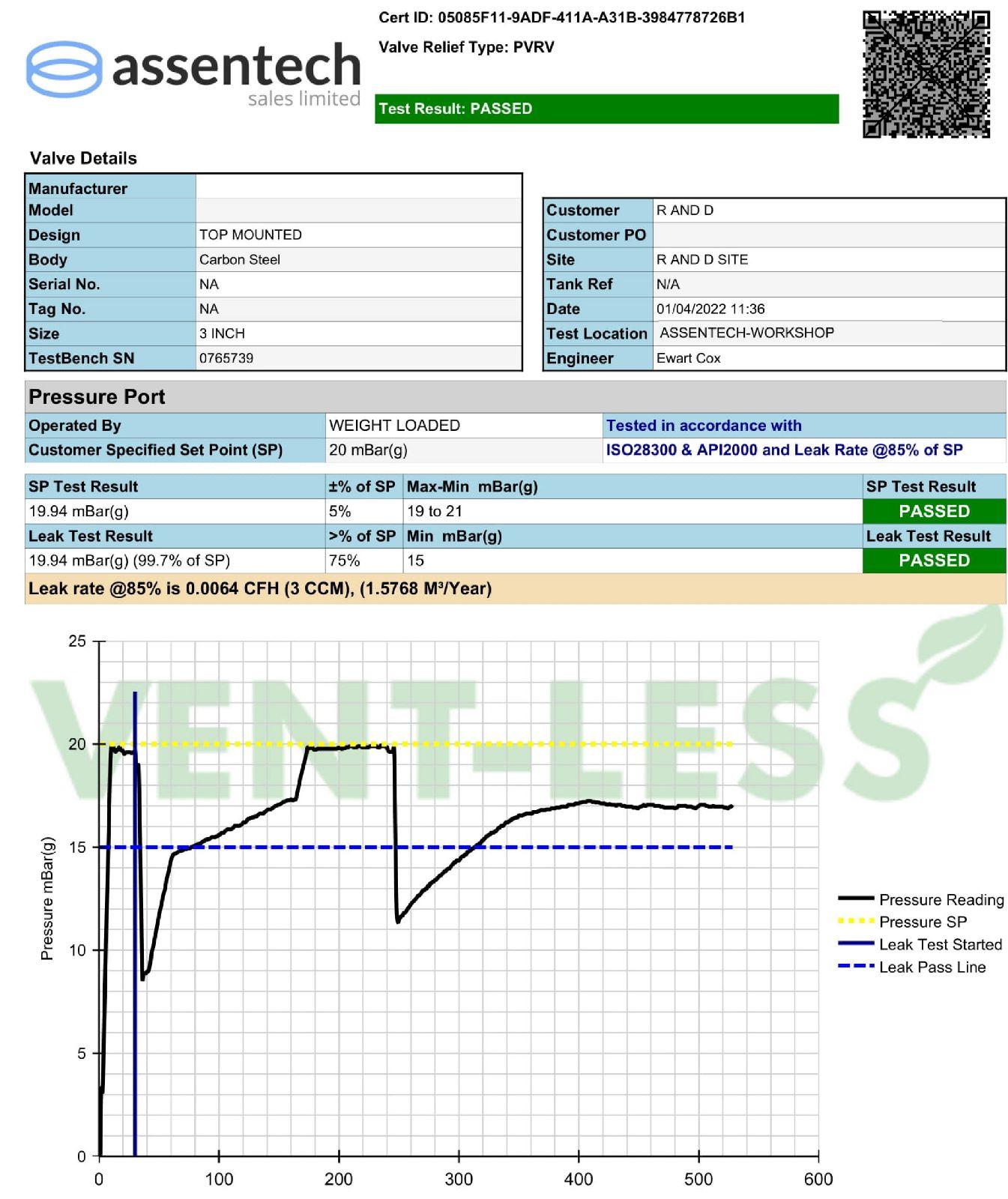

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation’s needs.

Fluid Transfer Equipment Product Range

Top Loading Arms

Swivels

Couplers and Adaptors

Rack monitors

Bottom Loading Arms

Top Loading Arms

Swivels

Assentech Academy – Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact