Stop wasting product and start monetising your vapours. Assentech, in partnership with VOCZero, delivers turnkey Vapour Recovery Systems that capture up to 99 % of volatile organic compounds (VOCs) from storage and loading operations—helping you stay compliant, safer and more profitable.

Why Recover Vapours?

- Recover valuable product: Up to 1 % of hydrocarbon liquids is lost to evaporation without mitigation—worth hundreds of thousands of pounds per year on a typical terminal.

- Rapid ROI: Typical payback on a VRU is just 12–24 months thanks to recovered product and avoided carbon‑credit costs.

- Protect people & planet: VOC capture prevents smog‑forming emissions, reduces odour complaints and eliminates explosive atmospheres.

The Assentech + VOCZero Advantage

- Carbon‑adsorption systems engineered to ASME VIII, B31.3, EN 60079 & EN 1127

- Fully ATEX‑compliant skids, pre‑wired and FAT‑tested for fast installation

- UK‑based service, spares and 24/7 remote monitoring support

Applications & Compatible Vapours

- Petrol, Diesel, E5–E100 Ethanol blends

- Methanol, Benzene, Toluene, Xylene, MTBE/ETBE

- Naphtha, Crude Oil, Gas Condensate

- Truck, rail, barge & ship loading, storage tank venting, pipeline pigging

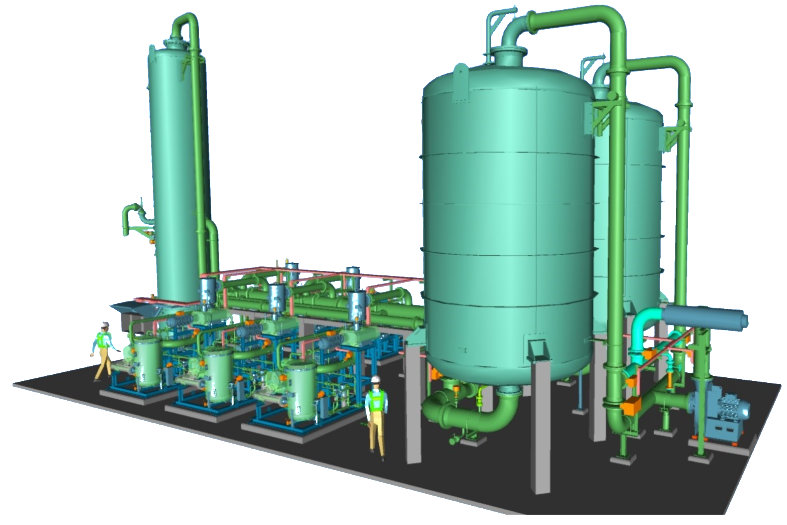

DTL Series – Energy‑Efficient 3‑Bed Technology

Our flagship DTL VRU handles vapour capacities from 100 m³/h to 6,000 m³/h in a single module. The patented Adsorber‑to‑Adsorber Equalisation (ATAE) cycle slashes vacuum energy by 20 %, delivering class‑leading OPEX.

Key Features

- Dual‑bed design with third‑bed energy‑saving cycle

- PLC with auto‑optimisation & remote diagnostics

- Hydrocarbon recovery ≥99 %

TRAC Series – Ultra‑Low VOC Emission (<1 ppm)

Steam‑regenerated activated‑carbon systems for petrochemical sites demanding parts‑per‑billion outlet concentrations.

Removal of Odorous Gasses from Vapour Streams

VZ ActiveVOC activated carbon is manufactured under stringent quality control, from scientifically selected grades of coal-based carbon. It is activated through a comprehensive controlled process, and pre-treated with chemical reagents, specifically for the removal of odorous gasses from vapour streams, in which hydrocarbons are present.

The filter contains VZ ActiveVOC filter material consisting of odorous selective activated carbon, which only is to be replaced when the capacity of the filter material is fully utilised.

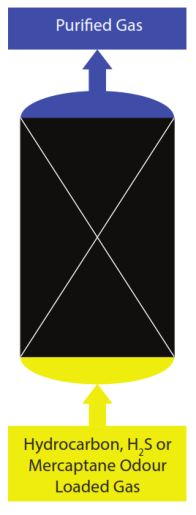

HYDROCARBONS, H2S AND MERCAPTANES ODOUR REMOVAL PROCESS

The Hydrocarbon, H2S or Mercaptane odorous loaded gas is passed into the odour removal unit in the bottom of the reactor vessel. The odorous components will be adsorbed onto the surface of the VZ ActiveVOC filler material, and the purified gas will leave the reactor from the top.

Why Assentech

Technical resource for best practice in tank maintenance

Advisors to both international Standards Committees

Technical advisor for HSE and the Environment Agency

Currently writing an environmental annexe for the International Standard

Authorised service partner with revolutionary testing, ensuring compliance

Technical resource for best practice in tank maintenance

Advisors to both international Standards Committees

Technical advisor for HSE and the Environment Agency

Currently writing an environmental annexe for the International Standard

Authorised service partner with revolutionary testing, ensuring compliance