Go back to News

Reducing methane emissions in the biogas industry to fight climate change

The biogas process is a brilliant source of renewable energy that supplies natural gas to communities. However, is the biogas industry as clean as it could be?

Since its establishment, Assentech has been on a mission to bring awareness to the dangers of gas leakages and support the tank storage industry to mitigate risks posed by inefficient equipment. With the awareness that the biogas industry is a huge contributor to methane pollution, Assentech is focusing on how it can support operators to become more aware of leaks and how to prevent them in the future.

Biogas mainly consists of methane (40–75%) and carbon dioxide (15–60%) which are greenhouse gases (GHG). There are also several other trace gases that usually make up less than 2% in volume. These include hydrogen sulphide (H2S), ammonia (NH3), hydrogen (H2), and nitrogen (N2).

These trace gases also create the potential for air pollution and acid rain, which can adversely impact soils and public health.

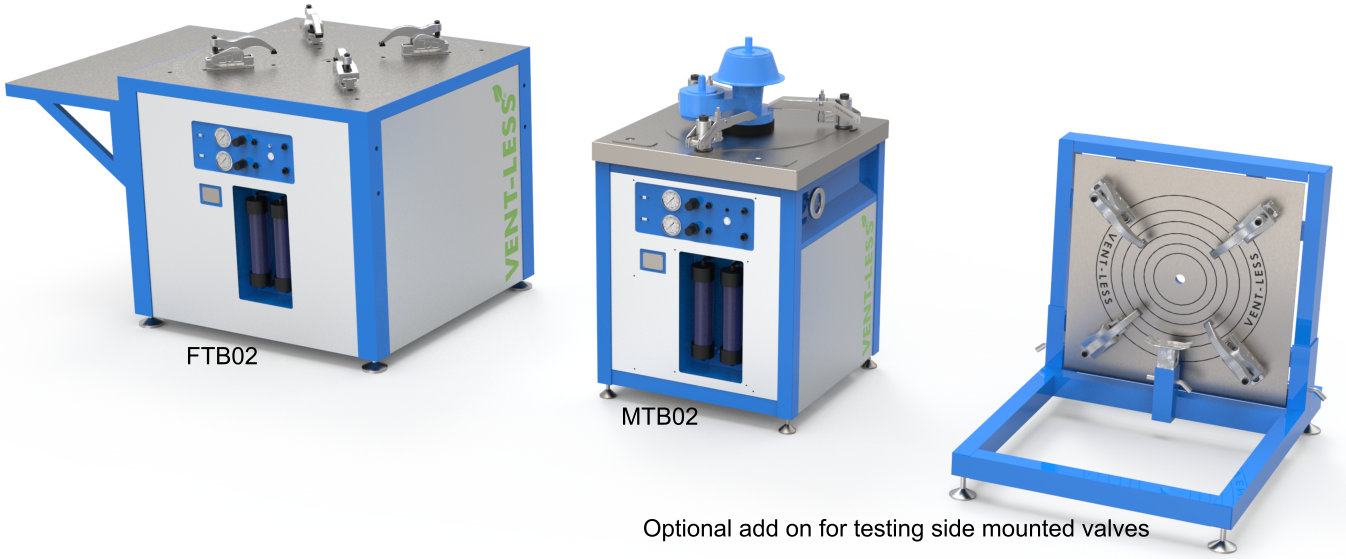

Patented Mobile Test Bench

Management of ageing plants or even checking new devices is important as you will read below. So, the Vent-Less test bench range by Assentech is good news for the industry. It will automatically run a functional test cycle on a tank breather vent and certify the results based on international standards.

Even with crucial equipment like these, the danger of fugitive emissions is still evident if they are not designed or tested in accordance with the international standards; API2000 and ISO28300. To ensure this it is important to insist on an individual leak test certificate. This must specify the serial number, flow recorded, calibrated equipment used and pressure achieved. Keep in mind that a batch certificate of conformance does not represent what functional tests was applied to the vent.

It’s going to require consistency across the biogas industry to ensure that harmful gases are kept inside tanks and utilised as biofuel instead of posing as a health and environmental threat. By understanding and acting upon the issue of fugitive emissions in the biogas industry, we can mitigate the risks and fight climate change.

Following COP21 in 2015 the IPCC drafted the Paris Agreement which set targets to keep global temperatures under 1.5 degrees over pre-industrial levels. This led all of the main accountancy firms to create a common reporting platform defining and declaring company activities affecting Environmental, Social and Governance (ESG) aspects.

Current predictions in 2021 ahead of COP26 indicate that we will exceed this target which will lead to increasingly adverse weather conditions and many other events that will affect all of us.

Mark Carney, UN Envoy for Climate Change has stated that those companies who adopt and invest in technology to reduce emissions will be seen as part of the solution and those that don’t will be seen as part of the problem.

Buyer beware!

The case study below shows actual test results showing the difference between low cost-inefficient valves and quality devices.

A low-cost vent manufacturer claimed leak tightness of less than 1 SCFH (standard cubic feet per hour) at 90% of setpoint (opening pressure). We purchased one of these vents. The manufacturer refused to issue an individual leak test certificate to evidence this claim. We tested the device and found it to be leaking more than 2 SCFH at 90% of the set point. This generated a loss equal to 496 cubic metres per year. That equates to 4.41 double-decker size gas clouds whereas a quality device was also tested and produced a leak rate of less than 0.01 SCFH or 2.4 cubic metres per year and 0.02 double-deckers.

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.